A Small Processing Plant Can Afford It

GUOGAO machinery offers a variety of stone crushing equipment at affordable prices for mining companies of all sizes, including artisanal miners, junior miners, and amateur mining enthusiasts.

GUOGAO machinery stone crushers can process most ores, such as iron ore, gold ore, limestone, quartz, river pebble, granite, bauxite, molybdenum ore, talc, silica sandstone gypsum dolomite manganese ore clay nickel ore etc.

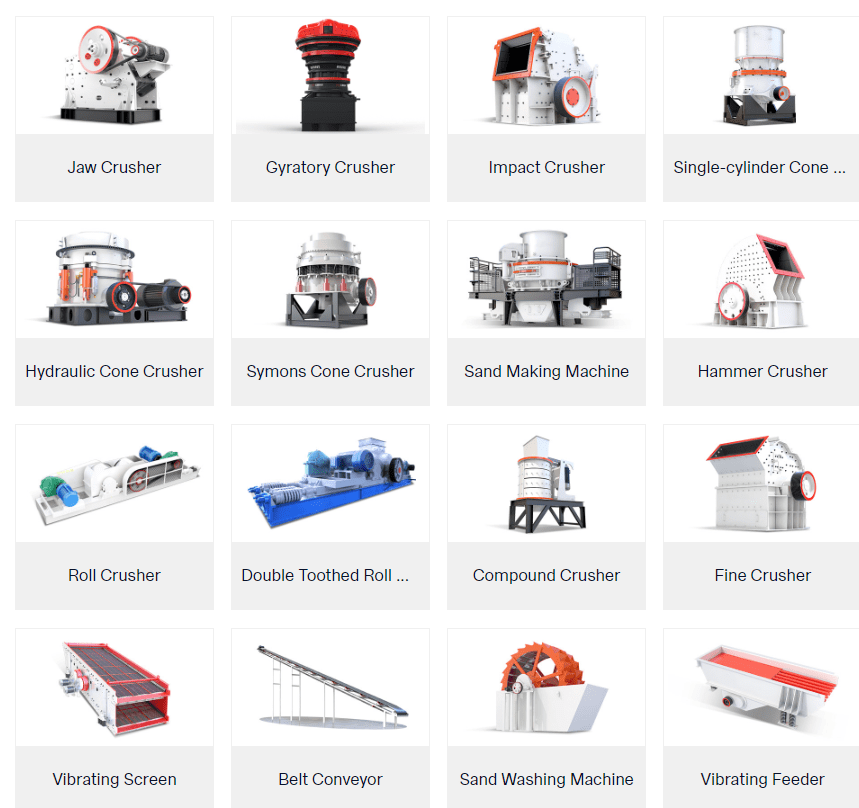

GUOGAO machinery Stone Crushing Equipment for Sale

You can customize your crushing machines at an affordable price based on different materials and particle sizes.

Even with a small budget many of our crushing machines allow you to process just a few kilos (pounds) each day and run your own small production line.

Before starting the beneficiation process, mineral testing should be conducted. Mineral testing helps determine the most suitable beneficiation method and select the appropriate equipment to achieve optimal product quality and maximum recovery rate.

1. Transportation Distribution Equipment

For very small-scale mining, manual or shovel-based transportation can be used.

① Vibrating Feeder: $1,000 per set (lowest price)

The vibrating feeder evenly feeds materials into crushing equipment.

Feed size: 300 mm-1,500 mm

Capacity: 80-1,500 t/h

② Belt Conveyor: $100 per set (lowest price)

2. Crushing Equipment

① Jaw Crusher: $1,000 per set (lowest price)

Used for coarse crushing (primary crushing) of rocks with any hardness.

Key component: jaw plates made of high-manganese steel.

Maximum feed size: 1,200 mm

Capacity: 1-2,200 t/h

② Cone Crusher: $5,000 per set (lowest price)

Used for medium and fine crushing. Maximum feed size is 480 mm. Maximum capacity is 2,020 t/h.

Single-cylinder Cone Crusher: Cost-effective option.

Symons Cone Crusher: Most popular choice, especially in Africa.

Hydraulic Cone Crusher: Best high-end option. Ideal for large crushing plants as it produces high-quality products with fewer needle-shaped stones and more uniform particle levels.

③ Impact Crusher: $1,000 per set (lowest price)

Used for primary, secondary and tertiary crushing.

Applicable materials include ores such as dolomite,

calcite,

limestone,

concrete asphalt,

and construction waste; can process materials with high moisture content.

Maximum feed size:

800 mm

Maximum capacity:

2,000 t/h

④ Hammer Crusher:

$976/ Set (the lowest price)

Used for medium and fine crushing of medium-hard and brittle materials.

One-time crushing without secondary crushing and shaping process. Produces small, uniform, and cubic output with minimal over-crushing.

Suitable for large-scale and high-yield production lines.

PCX Hammer Crusher: Maximum feed size is 300 mm. Maximum capacity is 1,200 t/h.

PCZ Heavy Hammer Crusher: Maximum feed size is 1,000 mm. Maximum capacity is 3,000 t/h.

⑤ Roller Crusher:

$3500/ Set (the lowest price)

One of the most economical and practical crushers.

Can handle first and second crushing of friable,

wet or sticky materials such as coal,

clay,

limestone,

slag,

and cement clinkers.

Maximum capacity: 110 t/h

⑥ Double Toothed Roll Crusher:

$6,500/ Set (the lowest price)

Used for medium and fine crushing of wet and viscous materials with medium hardness.

Crushed product size should not be less than 20 mm.

Maximum feed size: 120 mm

Maximum capacity: 390 t/h

Compared to other crushers, it has low noise levels and power consumption while being environmentally friendly.

⑦ Compound Crusher:

$1,000 per set (lowest price)

Ideal machine for crushing high-moisture materials.

Produces desired materials as feed for ball mills in raw cement meal production.

Capacity: 5-100 t/h

⑧ Fine Crusher

Used for fine to medium crushing purposes.

Can crush brittle materials with a hardness below 9 such as cement,

limestone,

marble,

talcum powder,

calcite,dolomite fluorite kaolin coal gypsum.

3. Screening Equipment

Vibrating Screen:

$1,000 per set (lowest price)

4. Sand Making and Washing Machine

① Sand Making Machine:

$1,000 per set (lowest price)

For high-quality finished products with sufficient budget: HVI Sand Making Machine.

For mobile operations: Mobile Sand Making Machine.

For cost-effective performance: VSI Sand Making Machine.

② Sand Washing Machine:

$6,000 per set (lowest price)

Removes impurities, recovers fine sand, and washes and dehydrates materials.

Essential for sand production lines, beneficiation processes, and building material production.

Machine models include Wheel-type Sand Washing Machine and Spiral Sand Washing Machine. Both machines effectively improve the quality of sand but operate differently.