Advantages

The Spiral Chute is the most effective equipment for mining and mineral processing. It combines the features of a spiral concentrator, shaking table, and centrifugal concentrator. Made of fiberglass with a wear-resistant polyurethane lining and corundum cover, it is lightweight, moisture-proof, and rust-resistant.

The spiral separator offers several advantages: it requires minimal space, consumes little water or energy, has a simple structure, high capacity, easy installation and operation, as well as low investment.

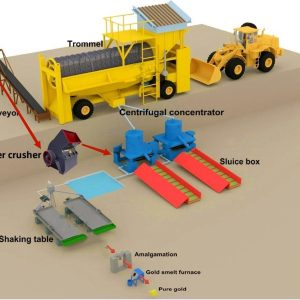

We offer various types of gravity separation equipment including gold centrifugal concentrators, shaking tables, and wet spiral concentrators (refer to our Mining Equipment List). The spiral classifier can be applied in different extraction processes such as dense media separation. Additionally, we provide customized designs for the spiral chute. Contact us via email to inquire about the price of the spiral classifier.

The Spiral separator, also known as the spiral chute, is an early mining machine used to classify fine-grained materials such as iron, tin, tungsten, tantalum-niobium, gold ore, coal mine, monazite, rutile, zircon and other metals. It can also separate non-metallic minerals with significant differences in specific gravity.

【Spiral chute principle】To operate the spiral chute: raise it and secure it in the correct position. The sand pump sends the ore to the feed inlet while adding water to adjust the slurry concentration. The slurry naturally swirls from high to low due to its rotating bevel flow rate. This generates an inertial centrifugal force that separates minerals from sand based on their specific gravity difference and grain size/shape. The concentrate flows into a designated bucket through a connected pipeline. Meanwhile, tailing sand flows into another bucket which is then connected to a sand pool via a pipeline. Finally, using a sand pump for drainage completes the entire beneficiation process.

Technical Parameters

| Model | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

| Outside Dia (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 |

| Pitch (mm) | 1200 | 540, 720 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 |

| Pitch Dia Ratio | 0.6 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 |

| Lateral Slope | 9° | 9° | 9° | 9° | 9° | 9° |

| Maximum Starts Per Column | 2 | 4-2 | 4-2 | 4-2 | 2 | 2 |

| Feeding Size (mm) | 2-0.04 | 0.3-0.02 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 |

| Feeding Density(%) | 30-55 | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 |

| Capacity (T/H) | 7-10 | 6-8 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 |

| Length (mm) | 2120 | 1560 | 1360 | 1060 | 700 | 460 |

| Size Width (mm) | 2120 | 1560 | 1360 | 1060 | 700 | 460 |

| Height (mm) | 5600 | 5230 | 5230 | 4000 | 2600 | 1500 |

| Weight (Kg) | 1200 | 800 | 600 | 400 | 150 | 50 |