A cone crusher reduces the size of rocks, stones, ores, and other materials between the mantle and concave through steady compression force.

The cone crusher has evolved from the initial spring cone crusher (often called Symons cone crusher) to hydraulic cone crushers with continuous improvement. Hydraulic cone crushers include single-cylinder and multi-cylinder types. Ftmmachinery offers these three types of cone crushers.

This article will introduce a single-cylinder cone crusher, referred to as a cone crusher for short.

GUOGAO machinery’s single-cylinder cone crushers have gained favor among customers in industries such as mining, recycling, and construction due to their optimized performance, automation system, minimal downtime, easy maintenance, and reliable operation.

Features of GUOGAO machinery’s single cylinder cone crushers:

Optimized performance

The single cylinder cone crusher combines speed, throw, crushing forces, and cavity design to provide higher capacity and superior end-product quality in secondary,

tertiary,

and quaternary applications.

Its unique crushing chamber and interparticle crushing principle result in excellent product shape,

high reduction ratio,

and high capacity.

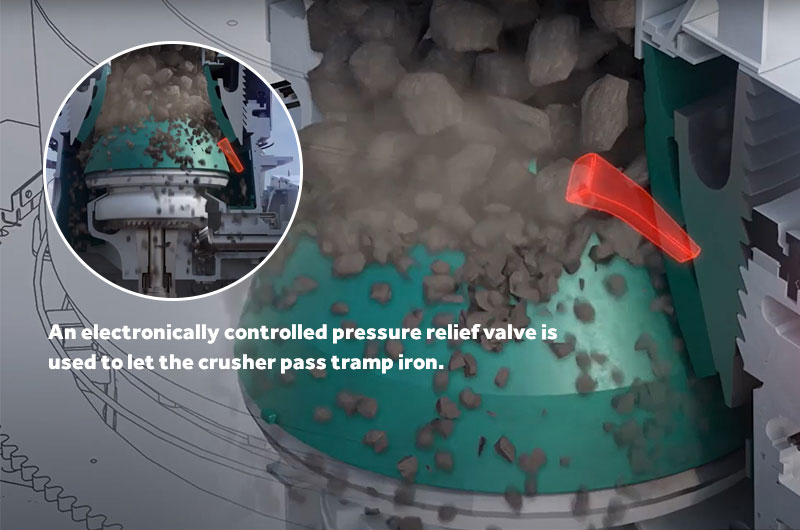

Automation system

The crusher automation system allows you to start or stop the equipment using the start/stop button. It also enables adjustment of key parameters based on your plant characteristics from the control room. Additionally,

it alerts you to harmful conditions like sudden changes in feed size or parts that require replacement.

Are made of high-quality materials, ensuring reliable performance and long service life.

The outer parts are designed with a streamlined appearance, making them easy to clean and maintain.

Easy maintenance for Ftmmachinery cone crushers

High efficiency

GUOGAO machinery cone crushers are equipped with advanced technology and optimized design, resulting in high crushing efficiency.

The unique crushing chamber design improves the utilization rate of materials and reduces energy consumption.

High-efficiency Ftmmachinery cone crushers

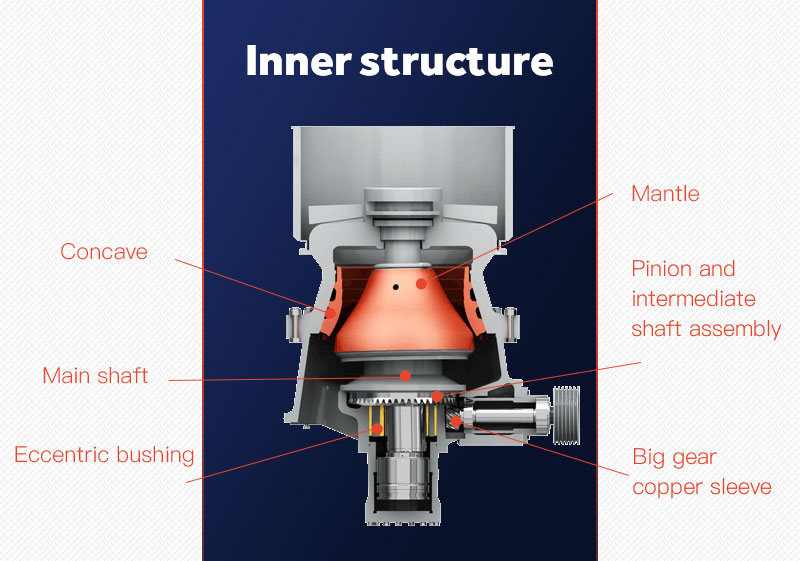

The main components of the cone crusher include concave, mantle, bowl-type bearing, copper bush, and main shaft.

Main Shaft

It is supported by a self-aligning bearing designed to accommodate the eccentric movement generated by the swing shaft. The feed materials are crushed by the eccentric movement of the main shaft.

Eccentric Drive and Bushing

The eccentric movement is generated from the lower eccentric bushing and the driving device located at the bottom of the main shaft.

The eccentric bushing is made of high-carbon steel with a bronze inner wear-resistant sleeve. The eccentric throw can be adjusted by installing sleeves of different sizes.

Concave

Also known as the fixed cone in a single-cylinder cone crusher. It is made of new composite material with features such as high anti-abrasion, high quality, reasonable prices, and wide application field.

Mantle

Also known as the movable cone. When a single-cylinder cone crusher operates, it closes or leaves the surface of concave to squeeze and crush materials.

Pinion and Intermediate Shaft Assembly

The alloy steel pinion is mounted on the pinion drive shaft. The external motor pulley provides power to rotate through gears between pinions and crown gear devices.

Big Gear Copper Sleeve

Used for sliding in conjunction with straight copper bush inside large gear assembly. Clearance available should be less than 5mm.

The main shaft inserts into cone copper bush creating gaps measuring approximately 3mm thick fuse during installation process.

Wearing Parts of Cone Crusher

The primary wearing parts are:

Mantle

Bowl lining

Concave

Feed cone

Main frame liner

Protection cone

Bushing

Pinions and gears

Adjustment rings and bowls

After long-term use, these wearing parts will inevitably wear out. Regular repair or replacement is necessary to maintain stable production and avoid unexpected downtime.

The main components of the cone crusher are the concave, mantle, bowl-type bearing, copper bush, and main shaft.

Main Shaft

It is supported by a self-aligning bearing designed to accommodate the eccentric movement generated by the swing shaft. The feed materials are crushed by the eccentric movement of the main shaft.

Eccentric Drive and Bushing

The eccentric movement is generated from the lower eccentric bushing and the driving device located at the bottom of the main shaft.

The eccentric bushing is made of high-carbon steel with a bronze inner wear-resistant sleeve. The eccentric throw can be adjusted by installing sleeves of different sizes.

Concave

Also known as the fixed cone in a single-cylinder cone crusher. It is made of new composite material with features such as high anti-abrasion, high quality, reasonable prices, and wide application field.

Mantle

Also known as the movable cone. When a single-cylinder cone crusher operates, it closes or leaves the surface of concave to squeeze and crush materials.

Pinion and Intermediate Shaft Assembly

The alloy steel pinion is mounted on the pinion drive shaft. The external motor pulley provides power to rotate through gears between pinions and crown gear devices.

Big Gear Copper Sleeve

Used for sliding in conjunction with straight copper bush inside large gear assembly. Clearance available should be less than 5mm.

The main shaft inserts into cone copper bush creating gaps measuring approximately 3mm thick fuse during installation process.

Wearing Parts of Cone Crusher

The primary wearing parts are:

Mantle

Bowl lining

Concave

Feed cone

Main frame liner

Protection cone

Bushing

Pinions and gears

Adjustment rings and bowls

After long-term use, these wearing parts will inevitably wear out. Regular repair or replacement is necessary to maintain stable production and avoid unexpected downtime.

Cone crushers are suitable for multiple stages of crushing. They can be used in secondary and tertiary stages, and sometimes even quaternary stages. The wide range of discharging sizes, such as 4-41mm in GUOGAO machinery cone crusher, allows for flexibility. In some cases, they can also be used in the first crushing stage if the material is small enough to fit through the feed opening.

Limitations of cone crushers

Although cone rock crushers are versatile, their feed opening size restricts them. They cannot crush material that is too large to fit through the feed opening. Hence, it is crucial for you to accurately determine the size distribution of the raw material and the feed size of the cone crusher.

Cone crushers are ideal for medium to hard mineral rocks and stones, but they are not suitable for softer materials like clay or shale as they can cause the machine to jam.

For sale: Cone crusher

GUOGAO machinery, a professional mining equipment manufacturer, offers durable cone crusher machines at factory prices starting from $5,000 per set.

We also assist customers in designing crushing plants with reasonable configurations and stable production.

Basalt crushing plant producing 300 tons per hour

Finished products: basalt gravel and sand

Applications: highway pavement, airport runways, port construction, expressways, railway ballast

Equipment configuration: jaw crusher, single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher

Parameter

Technical parameters of SC series single cylinder hydraulic cone crusher:

| Model | Cavities | Feeding Size (mm) | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Power (kw) | Capacity(t/h) |

| SC100S | C1 | 250 | 200 | 22 | 90 | 85-170 |

| C2 | 200 | 160 | 19 | 70-130 | ||

| SC160S | C1 | 360 | 290 | 25 | 160 | 125-345 |

| C2 | 300 | 240 | 22 | 108-305 | ||

| SC250S | C1 | 450 | 360 | 35 | 250 | 267-605 |

| C2 | 400 | 320 | 29 | 225-515 | ||

| SC315S | C1 | 560 | 450 | 41 | 315 | 349-1050 |

| C2 | 500 | 400 | 38 | 318-892 |

Technical parameters of SC series single cylinder hydraulic cone crusher:

| Model | Cavities | Feeding Size (mm) | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Power(kw) | Capacity (t/h) |

| SC100 | F1 | 150 | 120 | 10 | 90 | 45-135 |

| F2 | 90 | 70 | 10 | 43-118 | ||

| F3 | 38 | 30 | 4 | 25-40 | ||

| SC160 | F1 | 200 | 160 | 13 | 160 | 69-215 |

| F2 | 115 | 90 | 10 | 57-184 | ||

| F3 | 35 | 25 | 70-90 | |||

| SC250 | F1 | 240 | 190 | 16 | 250 | 116-396 |

| F2 | 140 | 110 | 13 | 97-346 | ||

| F3 | 70 | 55 | 9 | 90-251 | ||

| SC315 | F1 | 275 | 220 | 32 | 315 | 177-662 |

| F2 | 215 | 170 | 29 | 209-643 | ||

| F3 | 175 | 140 | 29 | 162-552 | ||

| F4 | 85 | 70 | 19 | 175-325 | ||

| SC560 | F1 | 300 | 240 | 22 | 560 | 448-1512 |

| F2 | 195 | 155 | 19 | 380-1373 | ||

| F3 | 90 | 70 | 13 | 357-912 | ||

| SC750 | F1 | 370 | 295 | 25 | 750 | 394-2181 |

| F2 | 300 | 240 | 19 | 342-2020 | ||

| F3 | 230 | 185 | 16 | 267-1814 | ||

| F4 | 120 | 95 | 13 | 248-1165 | ||

| F5 | 85 | 70 | 10 | 185-1170 |