1. What is a Raymond mill?

The Raymond mill, also known as the Raymond roller mill, combines grinding, classifying, and drying (if necessary) in one machine to produce precisely sized powders that meet specific production specifications. It is an efficient fine grinding machine for large-scale powder production.

Raymond mill: the star of fine powder grinding

2. Wide applications of Raymond mill

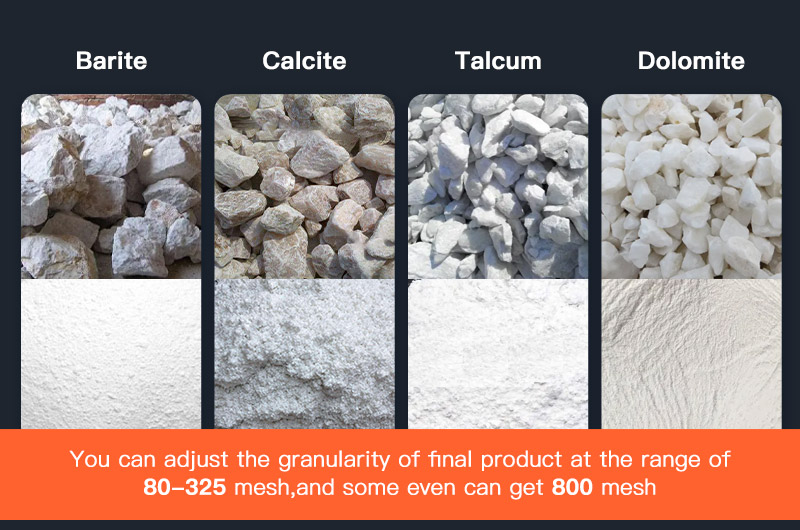

Raymond mill is widely used in the chemical fertilizer, chemical product, and mineral industries for grinding non-combustible and non-explosive non-metallic materials with a Mohs hardness below 9.3 and humidity below 6%.

It is an excellent grinding machine for barite, calcite, calcium carbonate, potassium feldspar, talc, marble, limestone,

dolomite,

fluorite,

lime,

activated clay,

activated carbon,

bentonite,

kaolin,

cement,

phosphate rock,

gypsum

and glass.

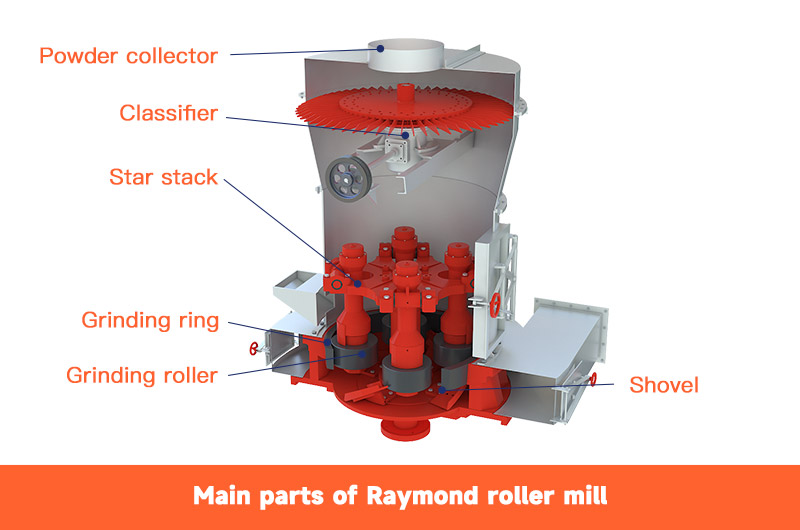

3. Raymond mill parts

Raymond mill mainly consists of rollers,

rings,

shovels,

shovel base,

bearings,

roller bushing,

spring for rollers,

roller hanger,

reducer,

main shaft,

bevel gear & pinion,

classifier,

blower

locking nut

roller assembly

snail shell

motor

elevator

chain

vibrating feeder

crusher

etc.

Main parts of raymond roller mills

Important parts and their functions:

Speed reducer:

Auxiliary speed reducer:

Used to reduce the speed of the rotating motor.

Grinding ring and rollers:

Materials are ground between the rollers and the grinding ring. As wearing parts of Raymond mills they are made from excellent wear-resistant materials to prolong equipment service life.

Blower:

Blows powder towards upper classifier for classification.

Classifier:

Classifies ground powders. The speed determines fineness of finished product.

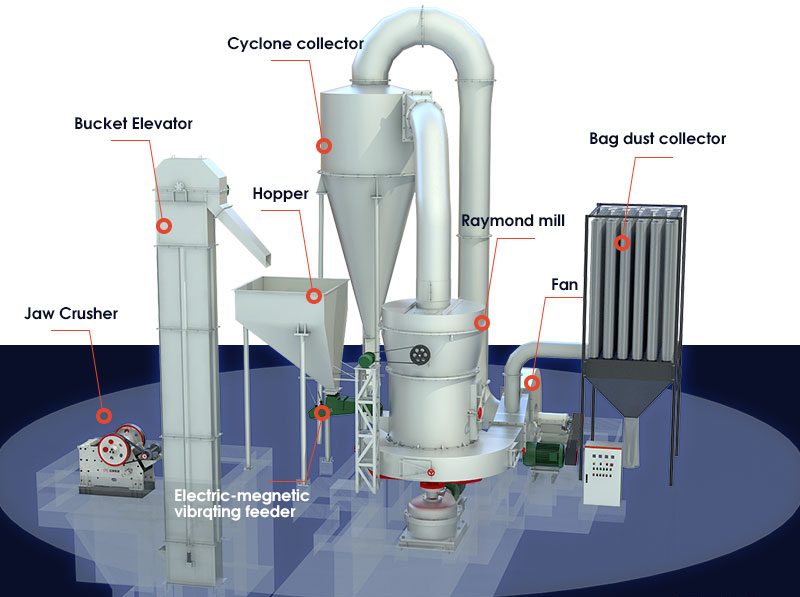

4. Raymond mill plant working principle

Step 1: Raw materials are crushed into specified particle size by a jaw crusher, lifted to the hopper by a bucket elevator, and then quantitatively sent into the grinding chamber by a feeding machine.

Step 2: Rotating shovels scoop up raw materials and project them between the rollers and the ring where grinding takes place.

Step 3: The pulverized powder is blown to the classifier by blower airflow for classification. Oversized particles fall back into the grinding chamber for regrinding. Qualified powders flow into cyclone collector through classifier and are collected as end products.

Step 4: To ensure that Raymond mill works under negative pressure, increased airflow enters pulse dust collector through pipe and is discharged into atmosphere after purification. Pulse collector enables dust-free operation in workshop.

5. Features of Ftmmachinery Raymond mill

1. Large output and high grinding efficiency:

Outputs range from 8 to176 tons per shift (8 hours). Finished powder has uniform fineness with passing rate as high as 99%.

2. Ability to produce powders of different particle sizes:

Different uses require different particle sizes of powder. Therefore, fineness of Raymond mill can be adjusted arbitrarily between 0.173mm and 0.044mm with achievable upper particle size of 800 mesh.

3.Low energy consumption:

Raymond pendulum mill achieves high requirements for grain size distribution easily and extremely energy efficiently even when highest demands regarding fineness need to be met.

4.Extremely robust and durable design:

Less vibration due to integral gearbox increasing mass of mill along with specially designed anti-vibration device.

Vibration reduction prevents cracking or damage caused by long-term vibration fatigue on frame or return box.

Important parts made from high-quality steel while wearing parts made from excellent wear-resistant materials improve wear resistance.

5.Environmental protection:

Good sealing performance ensures dust removal rate of 99% with full-pulse dust collector.

6.Automatic control:

Electrical system adopts centralized control, enabling grinding workshop to achieve unmanned operation.

Features of Ftmmachinery Raymond mill

6. Customer cases

Gypsum grinding plant in India

Output: 10-15 t/h

Finished particle size: 80 mesh-340 mesh (0.173 mm-0.044 mm)

Raw material: Gypsum

Raw material hardness: Soft

Feeding size: ≤100 mm

Production line type: Fixed

Purchasing equipment: PE-250 × 400 jaw crusher, 4525 Raymond mill, vibrating screen, conveyor, dust collector

Coal slag grinding plant in Thailand

Output: 300 kilotons per year

Finished particle size: 360 mesh (0.04 mm)

Raw material: ore slag

Raw material hardness: soft

Feeding size: ≤100 mm

Production line type: stationary/fixed

Equipment purchased: PE-250 × 400 jaw crusher, 4525 Raymond mill, vibrating screen, conveyor, dust collector

Quartz stone grinding plant in Pakistan

Output: 300 t/h

Finished particle size: 400 (0.038 mm)

Raw material: Quartz stone

Hardness of raw material: Hard

Feeding size: ≤25 mm

Type of production line: Fixed

Equipment purchased: CJ96 jaw crusher, 4119 Raymond mill, vibrating screen, conveyor, dust collector

Parameter

| Name | YGM7815 | YGM9517 | YGM4121 | YGM160 | |

| Ring rol number(pcs) | 3 | 4 | 5 | 6 | |

| Major diameter ofroler(mm) | Φ260X150 | Φ310X170 | Φ410X210 | Φ440X270 | |

| Inner diameter ofroller(mm) | Φ780 | Φ950X170 | Φ1280X210 | Φ1600X270 | |

| Revolving Speed(min) | 152 | 130 | 103 | 82 | |

| Max feed size(mmj) | <20 | <25 | <30 | <35 | |

| Final size(mm) | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 | |

| fineness can reach to 0.038 | fineness can reach to 0.038 | fineness can reach to 0.038 | fineness can reach to 0.038 | ||

| Output(th) | 1~5 | 3~8 | 6~11 | 9~22 | |

| Conmplete physical size(mm) | 4300x3500x5100 | 7100* 5900* 7900 | 9200* 7250*9700 | 12550*5700* 8355 | |

| Main uit motor | Model | Y180M-4 | Y225S-4 | Y280S-4 | Y315M-4 |

| Power(kw) | 18.5 | 37 | 75 | 132 | |

| Rotate speed(min) | 1480 | 1480 | 1480 | 1480 | |

| Centifugalinduced draft fan motor | Model | Y160L-4 | Y225S-4 | Y280S-4 | Y315M-4 |

| Power(kw) | 15 | 37 | 75 | 132 | |

| Rotate speed(min) | 1480 | 1480 | 1480 | 1480 | |

| Classifier speed regulating motor | Model | YCT160-4A | YCT200-4A | YCT200_4B | YCT250-4A |

| Power(kw) | 22 | 5.5 | 7.5 | 18.5 | |

| Rotate speed(min) | 125-1250 | 125-1250 | 125-1250 | 132-1320 | |

| Elevator | Elevator model | TH200*8 | TH200*8 | TH200*8 | TH300*9 |

| Motor model | Y100L2-4 | Y100L2-4 | Y100L2-4 | Y112M-4 | |

| Power(kw) | 3 | 3 | 3 | 4 | |

| Rotate speed(min) | 1430 | 1430 | 1430 | 1440 | |

| Jaw Crusher | Jaw Crusher Model | PEX150x250 | PE200*350 | PE250*400 | PE250* 750 |

| Main umit motor | Y132S-4 | Y160M-6 | Y180L-6 | Y200L2-6 | |

| Power(kw) | 5.5 | 7.5 | 15 | 22 | |

| Rotate speed(min) | 970 | 970 | 970 | 970 | |

| Magnetic vibrating feeder | Main uit motor | GZ1F | GZ2F | GZ3F | GZ3F |

| Power(kw) | 0.06 | 0.15 | 0.2 | 0.2 | |