A concise overview of the powder grinding production line

The powder grinding production line is extensively used in a variety of industries such as building materials, chemical engineering, chemicals, mining, medical research, construction, and others. It is employed for grinding materials to sizes ranging from 80 to 3000 meshes.

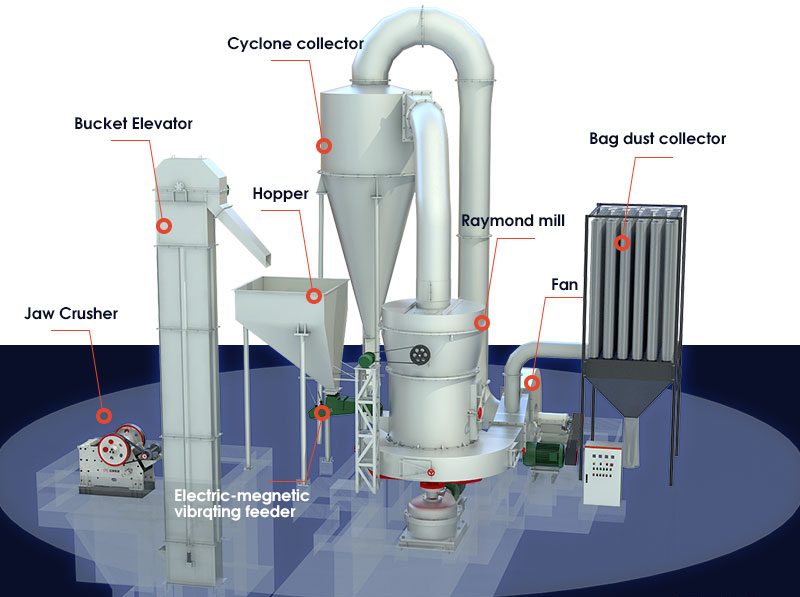

Composition of powder grinding line

The powder grinding line is equipped with various machines such as a jaw crusher, hopper, bucket elevator, classifier, dust collector, high-pressure mill, reducer, vibrating feeder, and air-blower.

It has simple technical procedures and low investment costs. Additionally, it has a profitable market which greatly promotes the grinding business both domestically and internationally.

Handling materials in the powder production line:

It can grind non-flammable and non-explosive minerals with a hardness below grade eight and moisture content below 6%. These minerals include feldspar, calcite, talc, barite, fluorite,rare earths , marble,c eramics , bauxite,manganese ore , phosphate ore,silica sand,and activated carbon.

Applications of powder grinding line

Advantages of powder grinding line:

The grinding technology is advanced, with high-quality and reliable machines that have a cost-effective and durable service life.

The grinding process is simple, with a large ore processing capacity resulting in over 40% increased output.

The efficiency of the entire production line is extremely high, ensuring safe and stable operation with an exceptionally low failure rate.

It has low energy and electricity consumption, minimal resource waste, low investment costs, and high profitability.

It achieves a good grinding effect with a high powder yield. The finished powder has uniform fineness and fewer impurities.

Powder grinding flow:

The powder grinding flow typically consists of three phases: crushing, grinding, and collecting. The main phase involves using a grinding machine for processing. The main technical process is as follows:

1. Crushing

The vibrating feeder sends large stones or minerals to the jaw crusher for primary crushing, reducing them to the required size (below 25 or 30 mm).

Afterwards, the materials are transferred to the stock bin using a bucket elevator.

Equipment used: vibrating feeder, jaw crusher, bucket elevator.

2. Grinding

The materials in the stock bin are evenly transferred to the grinding machine using an electromagnetic vibrating feeder for further grinding (to a size of 80 to 3000 mesh).

The ground materials are then conveyed by airflow and classified by the analyzer.

Related equipment: electromagnetic vibrating feeder, grinding machine, analyzer.

3. Collecting

After being classified, the powder that meets the requirements is collected by a powder collector and sent into another bin through a pipeline.

Related equipment: powder collector, dust collector.

Customer case

20 TPH powder grinding line in Indonesia

Product Details:

| Application | Industrial |

| Material | Marble |

| Capacity | 20 tons per hour |

| Driven Type | Electric |

| Main equipment | Jaw crusher, Raymond grinding machine |

| Feeding size | 30 MM |

| Discharging size | 30-200 meshes |

10 TPH powder grinding line in India

Product Details:

| Application | Industrial |

| Material | Limestone |

| Capacity | 10 tons per hour |

| Driven Type | Electric |

| Main equipment | Raymond grinding machine |

| Feeding size | 50 MM |

| Discharging size | 150 meshes |

2 TPH powder grinding line in Pakistan

Product Details:

| Application | Industrial |

| Material | Gypsum |

| Capacity | 2 tons per hour |

| Driven Type | Electric |

| Main equipment | HGM German high-efficiency powder grinding mill |

| Feeding size | 25 MM |

| Discharging size | 100-200 meshes |

5 TPH powder grinding line in Zambia

Product Details:

| Application | Industrial |

| Material | Talcum |

| Capacity | 5 tons per hour |

| Driven Type | Electric |

| Main equipment | HGM German high-efficiency powder grinding mill |

| Feeding size | 30 MM |

| Discharging size | 300 meshes |

Why choose Fote’s powder grinding plant?

GUOGAO Machinery is a professional manufacturer of powder grinding machines, with decades of experience and a deep understanding of the current state of the powder industry.

By incorporating manufacturing techniques from Germany, Fote Heavy Machinery offers a scientifically designed and efficient powder grinding production line that is customized to meet customers’ specific requirements. It comes with the following advantages and features:

The production line operates smoothly with a small footprint, low investment, high capacity, high efficiency, and wide applicability.

The crushers and grinding mill equipped in the production line are ingeniously designed to ensure normal operation, reduce maintenance frequency, and increase service life by more than three times.

The entire production process has a high degree of automation, allowing for remote operation and reducing labor and time costs.

Machines produced by Fote Heavy Machinery have low energy consumption and dust emissions, achieving ideal energy-saving and environmental protection in production.

The powder grinding production line for sale is affordable yet reliable in quality, making it popular among domestic and international enterprises.

If you are interested in our powder grinding line or have any questions about grinding, please consult us online or via email. Our professional engineers will respond as soon as possible.

FAQs about the powder grinding production line:

What is the optimal humidity for materials processed in the powder grinding production line?

It is best to keep the humidity below 7% to achieve optimal grinding effects. If the material is too wet, it may negatively affect the efficiency and effectiveness of the machine.

What should I do if the grinding fineness does not meet the requirements of finished products?

You can control the grinding fineness by adjusting the speed of both the powder concentrator and fan.

How do I choose a suitable powder grinding production line?

The key machine in a powder grinding line is a powder grinder/mill which affects overall performance. Two factors can be considered when choosing an appropriate mill:

① The choice can be based on desired particle size. In general terms: ball mills produce particles ranging from 150 to 250 meshes; Raymond mills produce particles ranging from 80 to 325 meshes; HGM mills produce particles ranging from 80 to 800 meshes; while three-ring medium-speed micro-powder mills can reach up to 2000 meshes.

② The nature of materials also influences the choice of powder grinding mill. For materials with high hardness, ball mills are recommended; for those with medium hardness, Raymond mills and HGM German high-efficiency powder grinding mills are suitable.

Parameter

| Name | YGM7815 | YGM9517 | YGM4121 | YGM160 | |

| Ring rol number(pcs) | 3 | 4 | 5 | 6 | |

| Major diameter ofroler(mm) | Φ260X150 | Φ310X170 | Φ410X210 | Φ440X270 | |

| Inner diameter ofroller(mm) | Φ780 | Φ950X170 | Φ1280X210 | Φ1600X270 | |

| Revolving Speed(min) | 152 | 130 | 103 | 82 | |

| Max feed size(mmj) | <20 | <25 | <30 | <35 | |

| Final size(mm) | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 | 1.6-0.045 | |

| fineness can reach to 0.038 | fineness can reach to 0.038 | fineness can reach to 0.038 | fineness can reach to 0.038 | ||

| Output(th) | 1~5 | 3~8 | 6~11 | 9~22 | |

| Conmplete physical size(mm) | 4300x3500x5100 | 7100* 5900* 7900 | 9200* 7250*9700 | 12550*5700* 8355 | |

| Main uit motor | Model | Y180M-4 | Y225S-4 | Y280S-4 | Y315M-4 |

| Power(kw) | 18.5 | 37 | 75 | 132 | |

| Rotate speed(min) | 1480 | 1480 | 1480 | 1480 | |

| Centifugalinduced draft fan motor | Model | Y160L-4 | Y225S-4 | Y280S-4 | Y315M-4 |

| Power(kw) | 15 | 37 | 75 | 132 | |

| Rotate speed(min) | 1480 | 1480 | 1480 | 1480 | |

| Classifier speed regulating motor | Model | YCT160-4A | YCT200-4A | YCT200_4B | YCT250-4A |

| Power(kw) | 22 | 5.5 | 7.5 | 18.5 | |

| Rotate speed(min) | 125-1250 | 125-1250 | 125-1250 | 132-1320 | |

| Elevator | Elevator model | TH200*8 | TH200*8 | TH200*8 | TH300*9 |

| Motor model | Y100L2-4 | Y100L2-4 | Y100L2-4 | Y112M-4 | |

| Power(kw) | 3 | 3 | 3 | 4 | |

| Rotate speed(min) | 1430 | 1430 | 1430 | 1440 | |

| Jaw Crusher | Jaw Crusher Model | PEX150x250 | PE200*350 | PE250*400 | PE250* 750 |

| Main umit motor | Y132S-4 | Y160M-6 | Y180L-6 | Y200L2-6 | |

| Power(kw) | 5.5 | 7.5 | 15 | 22 | |

| Rotate speed(min) | 970 | 970 | 970 | 970 | |

| Magnetic vibrating feeder | Main uit motor | GZ1F | GZ2F | GZ3F | GZ3F |

| Power(kw) | 0.06 | 0.15 | 0.2 | 0.2 | |