Placer gold washing plant sand mix rock stone together

Placer Gold Mining Process

The goal of placer/alluvial gold mining is to maximize the recovery of gold and associated heavy minerals from gangue.

Placer gold washing:

This crucial step precedes the separation of placer gold. Its primary objective is to separate gravel, sand, and granular soil while also removing fine mud adhering to the gravel and any mixed-in gold ore.

Placer gold Screening:

The main purpose here is to screen the placer gold ore after washing in order to eliminate large pieces of non-gold-bearing gravel and enhance the efficiency of gold recovery.

Gravity separation: Since placer gold exists in a free state and has a noticeable difference in specific gravity compared to sand, using gravity separation is an ideal method for extracting gold from placer ore.

Concentrate processing:

In cases where gold contains various metal minerals or impurities, additional processes such as gravity separation, magnetic separation, flotation, electric separation or their combination can be utilized for mutual isolation. These processes further improve the grade of extracted gold.

50tons/hour Sand + Rock gold washing&crushing extract plant, equiplist list

Washing Unit Model: MGT50, Capacity 50tons/h, Power 70kw,

Fine crusher PC600x400, 22KW

water supply 130m3/h,wheels 4nos, Recovery Rate 98% ,

Size 7000*2500*3000mm

Detail list:

Fedder Hopper size 2000*1500mm

Clay Scrubber size 1000*1500mm

Trommel Screen size 1300*2500mm

Gold Centrifuge concentrator 1 set

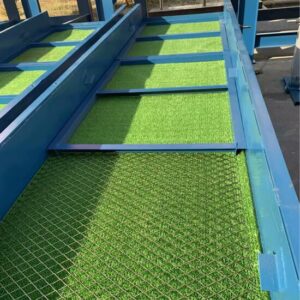

Sluice Box 3 sets

Mercury Amalgamator&gold smelting fumace 1sets

Water supply system 1set

Electric control cabinet 1set

Shaking table 2set

Pipes and Accessories

100tons/hour Sand + Rock gold washing&crushing extract plant, equiplist list

Washing Unit Model: MGT100, Capacity 100tons/h, Power 120kw,

Fine crusher PC800x600, 55KW

water supply 240m3/h,wheels 10nos, Recovery Rate 98% ,

Size 8300*2400*4700mm

Detail list:

Fedder Hopper size 3000*2000mm

Clay Scrubber size 1200*3000mm

Trommel Screen size 1500*3500mm

Gold Centrifuge concentrator 2 set

Sluice Box 4 sets

Mercury Amalgamator&gold smelting fumace 1sets

Water supply system 1set

Electric control cabinet 1set

Shaking table 4sets

Pipes and Accessories

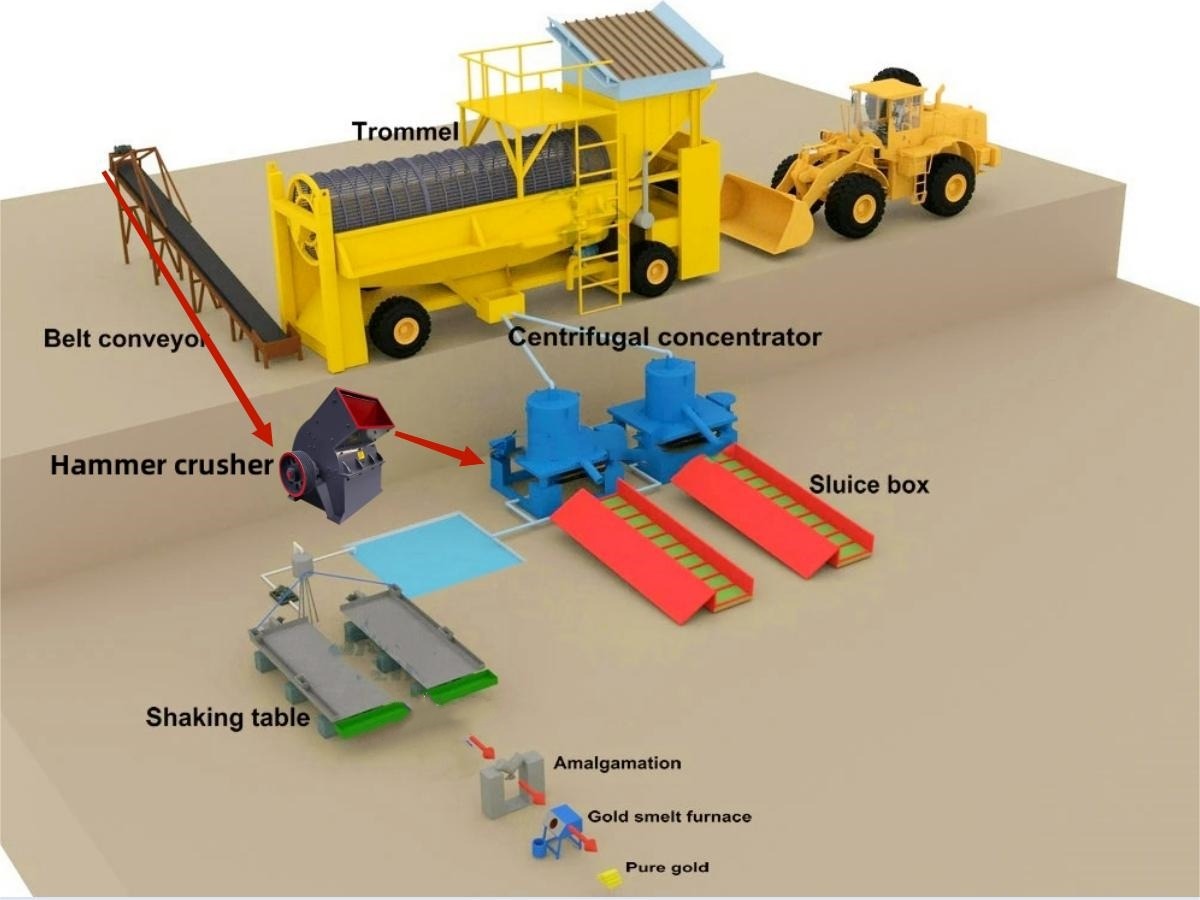

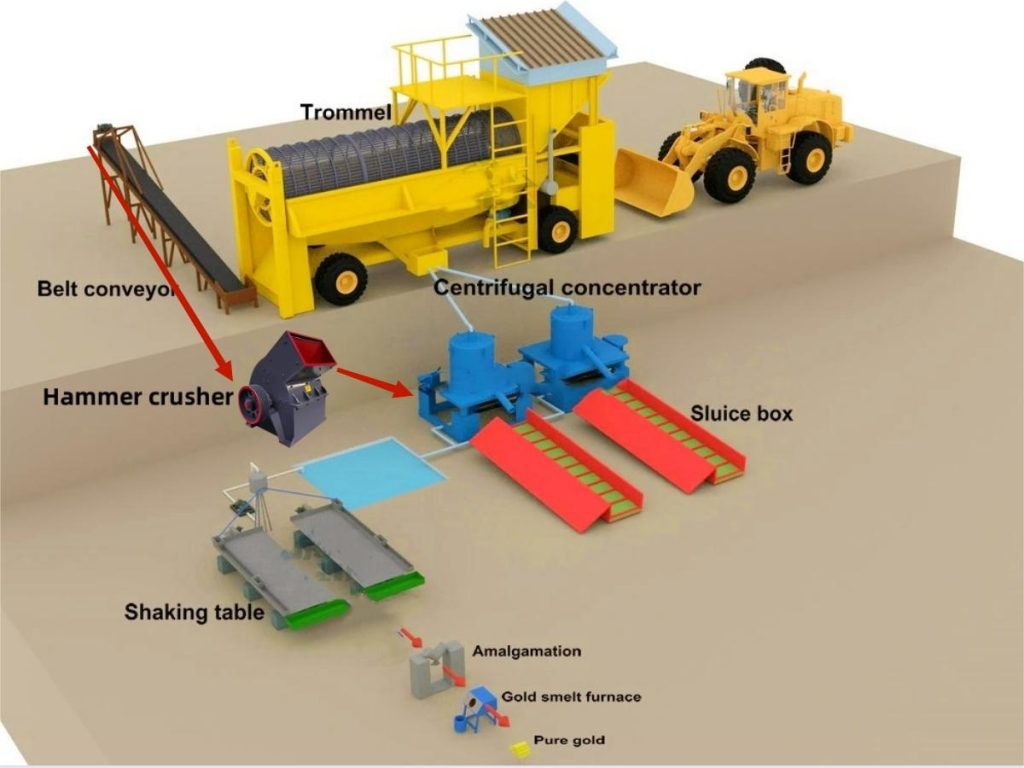

Process diagram

washing and Concentrate unit

Fine cuhser for rock stone

shaking table for gold extraction

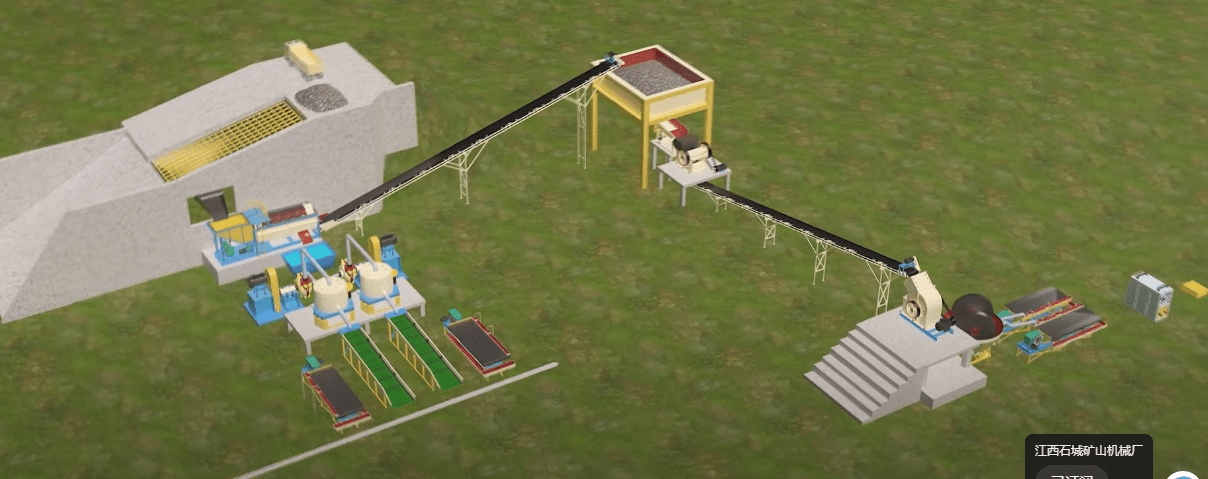

Blow is viedo of Mobile Placer gold washing plant sand mix rock mining

Added Gold Centrifuge concentrator in reality

Blow is viedo of Fixed Placer gold washing plant sand mix rock mining

gold centrifuge ,fine cruser, wet pan mill

If you are interested in ordering, please contact us

PHONE NUMBER

+86-15836546239(WhatsApp)