Placer Gold Mining Process

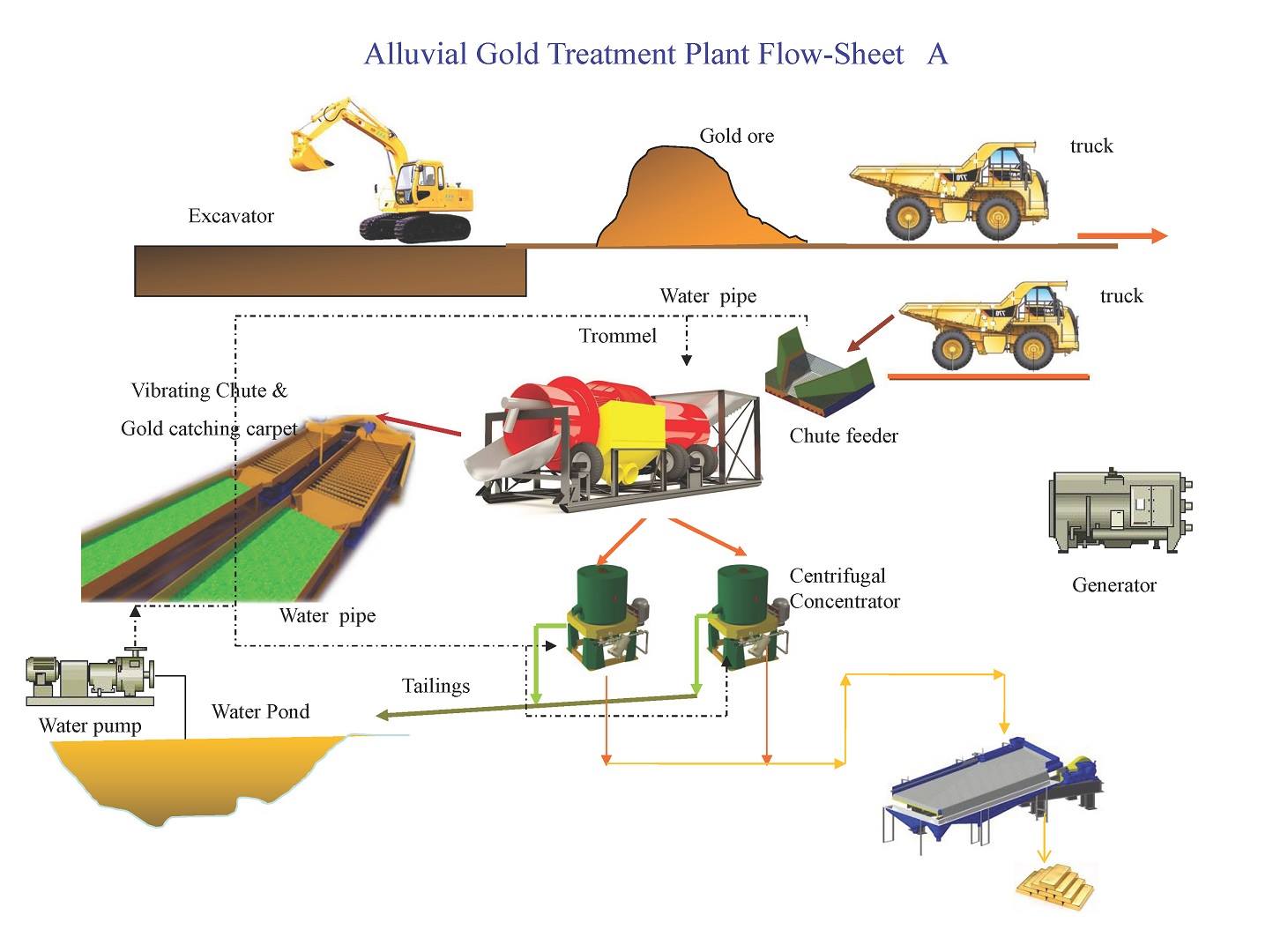

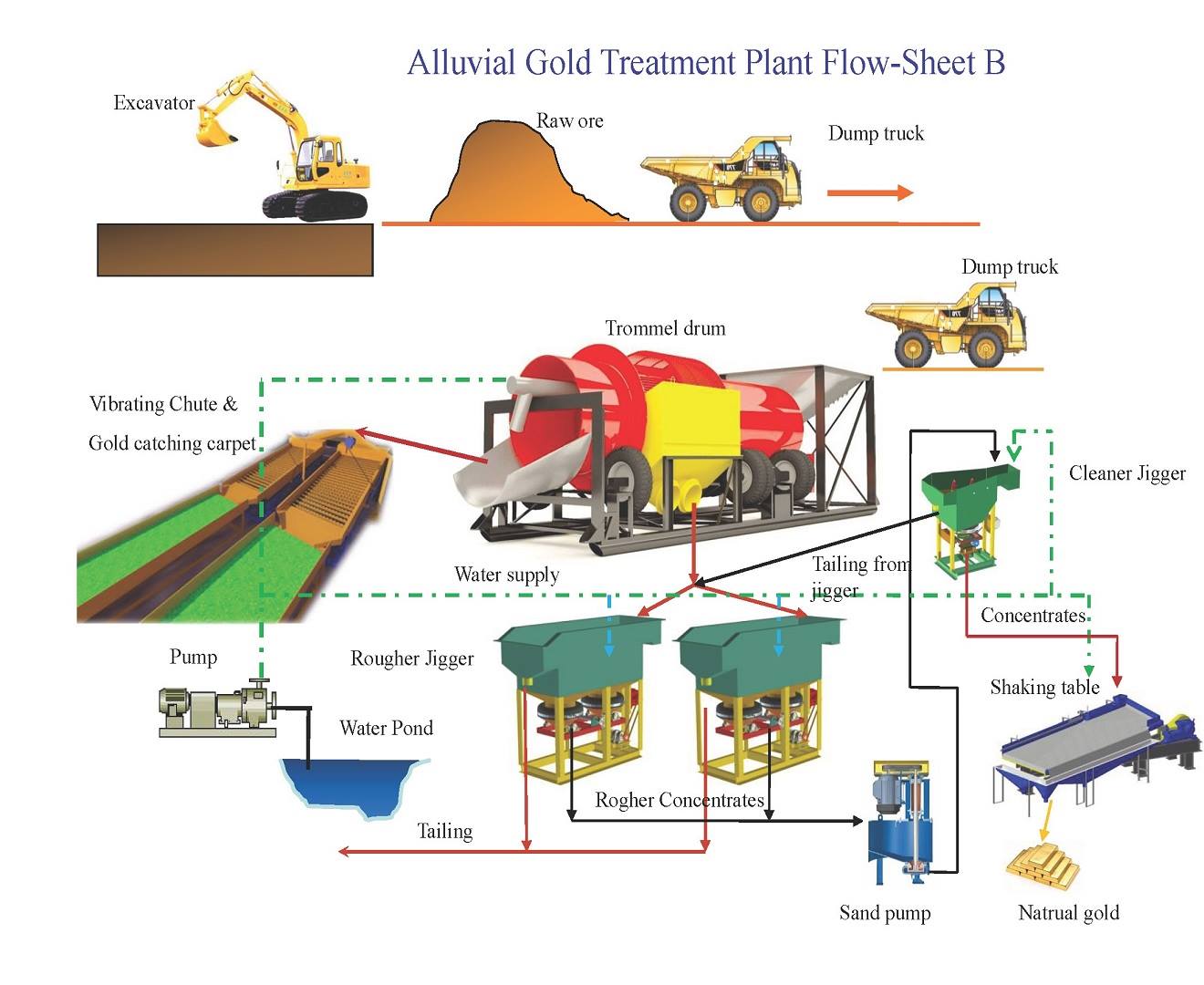

The process of placer/alluvial gold mining aims to maximize the recovery of gold and associated heavy minerals from gangue. Subsequently,

A combined mining scheme involving gravity, flotation, magnetic, and electrostatic separation is employed to separate gold from the associated heavy minerals.

Ore washing: This crucial step precedes the separation of placer gold. Its primary objective is to separate gravel, sand, and granular soil while also removing fine mud adhering to the gravel and any mixed-in gold ore.

Screening: The main purpose here is to screen the placer gold ore after washing in order to eliminate large pieces of non-gold-bearing gravel and enhance the efficiency of gold recovery.

Gravity separation: Given that placer gold exists in a free state and exhibits an obvious difference in specific gravity compared to sand, employing gravity separation is an ideal method for extracting gold from placer ore.

Concentrate processing: In cases where gold contains various metal minerals or impurities, additional processes such as gravity separation, magnetic separation, flotation, electric separation or their combination can be utilized for mutual isolation. These processes further improve the grade of extracted gold.

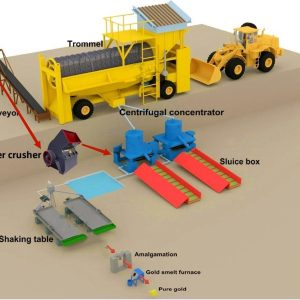

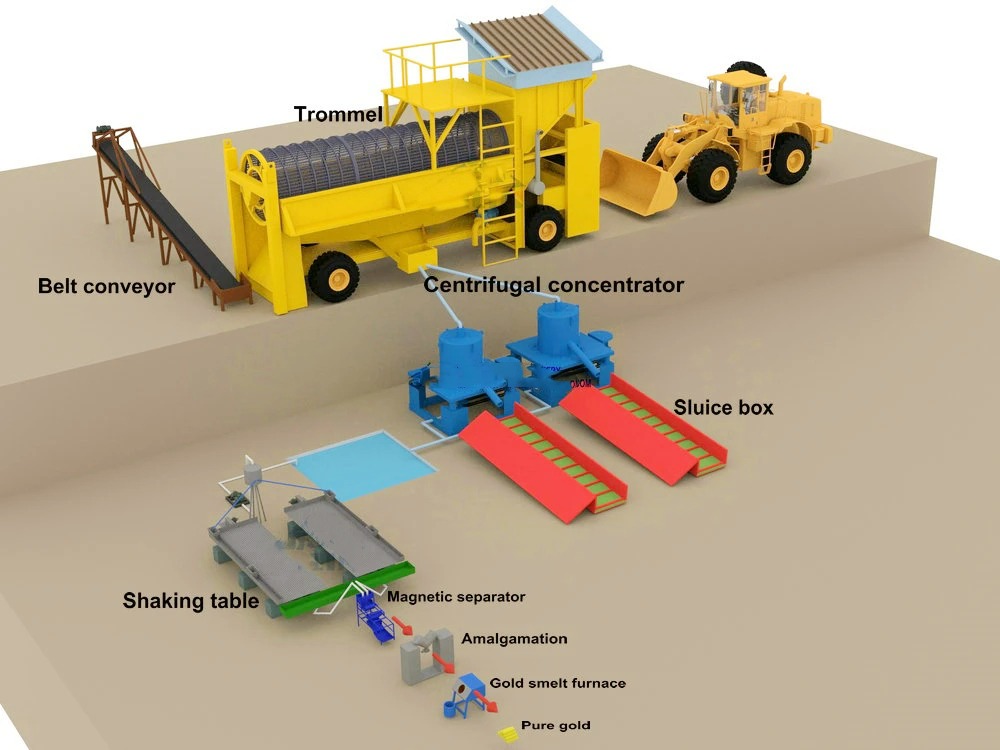

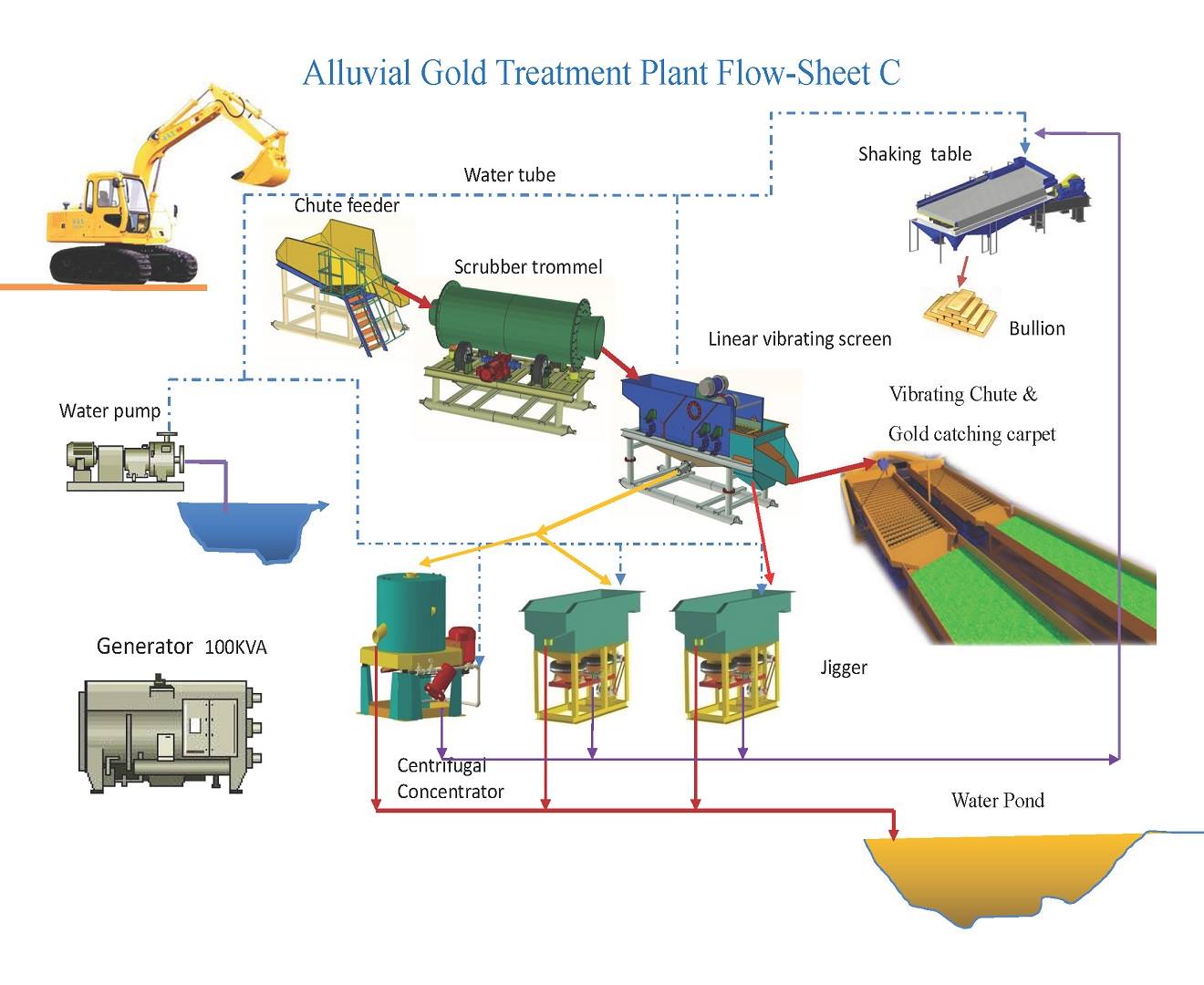

This setup is a 100tph complete alluvial gold processing plant

The main equipment and process details are as follows:

Trommel scrubber

Drum magnetic separator

Centrifugal concentrator

Shaking table

Gold sluice box

Gold melting furnace

Raw ore information:

The raw material is alluvial gold ore with clay, ranging from 0-150mm in size. The gold nuggets are approximately 0-10mm in size and contain some magnetic ores.

1. Feeding stage:

The truck unloads the material into the hopper, which then enters the vibrating feeder from below. The vibrating feeder grate separates out waste materials larger than 100mm, which are transferred to the stockyard via a belt conveyor.

2. Washing stage:

The vibrating feeder evenly feeds the material smaller than 100mm into the trommel scrubber for washing. The trommel scrubber has two layers of screens with mesh sizes of 2mm and 10mm.

3. Gravity Separation:

Material sized between 2-10mm flows into a gold sluice box to capture particles of gold within that range. Material larger than 10mm is sent to a waste pile.

Meanwhile, material between 0-2mm in the slurry pool is pumped from there to a centrifuge concentrator where it undergoes further processing.

Tailings from this process flow back into the gold sluice box for concentration purposes. Finally, concentrated gold flows onto a shaking table for further refinement and can be smelted in a melting furnace to obtain gold nuggets.

This process offers environmental protection benefits as tailings can be directly discharged, significantly reducing construction costs for processing plants overall. We also offer fixed and mobile gold wash plants suitable for small/medium-scale processing plants at low cost but high recovery efficiency.

Welcome to order and contact us

If you are interested in ordering, please contact us

PHONE NUMBER

+86-15836546239(WhatsApp)