What is a portable crusher?

A portable rock crusher, also known as a wheeled mobile crusher or wheeled crushing plant, can be easily transported during the mining process. The most notable characteristic of the portable crusher is its ability to be moved from one location to another using vehicle traction.

The wheeled crushing station is a large-scale mobile crushing equipment designed by GUOGAO Machinery. It can accommodate various types of main engines and is commonly used in building materials, metallurgy, aggregate mining, and recycling. This portable crusher is particularly useful in areas like roads, railways, and construction waste management where the relocation of processed materials is necessary.

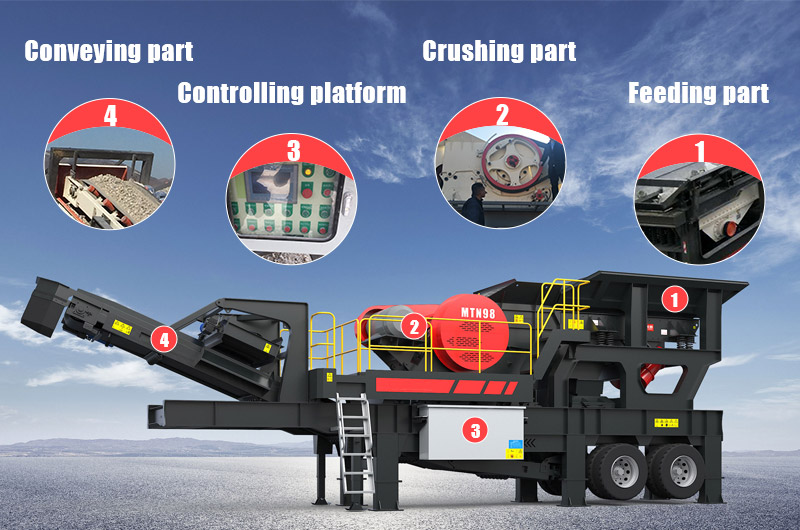

1. Feeding Section

The feeding section is responsible for delivering raw materials to the crusher chamber for processing. It typically consists of a vibrating feeder that extracts and regulates the flow of material into the crusher.

2. Crushing Section

The main equipment in the crushing platform is the crusher machine, which determines the processing capacity of the crushing system. The type of crusher used in portable machines can vary depending on specific applications and desired final products.

3. Control Platform

In the control room, PLC technology is used to control the operation of the crusher, feeder, and conveyor. Operators can monitor operating voltage and current for each drive device, as well as oversee material crushing processes in real-time.

4. Conveying Section

The conveying section is responsible for transporting crushed materials to subsequent crushing stages or hoppers. It includes components such as conveyor belts, belt pulleys, and drive systems.

Types of Portable Rock Crushers

1. Portable Jaw Crusher

A portable jaw crusher is used for coarse crushing materials; it’s also known as a wheeled jaw crusher plant. It features a large crushing ratio and deep cavity design primarily suited for crushing large rocks.

Matching Method: Jaw Crusher + Feeder + Conveyor Belt + Vehicle Body

Common jaw crusher models:HD86, HD98, HD110, HD125

Maximum feed size:≤800 mm

Output size:50-225 mm

Capacity:85-650 t/h

2. Portable Cone Crusher

A portable cone crusher, also known as a wheeled cone crusher plant, is used for medium and fine crushing of materials. It is suitable for crushing materials with small particle sizes and high hardness, often serving as a secondary crusher after the jaw crusher.

Matching Method: Cone Crusher + Vibrating Screening Machine + Conveyor Belt + Vehicle Body

Commonly cone crusher models:GYS300, GYS400, HP300

Maximum feed size:≤190 mm

Output size:3-51 mm

Capacity:36-445 t/h

3. Portable Impact Crusher

A portable impact crusher, also known as a wheeled impact crusher plant, is a secondary crushing equipment. Its primary application is the recycling of construction waste, offering both high output and a certain plastic effect.

Matching method: Impact crusher + vibrating screening machine + conveyor belt + vehicle body

Common impact crusher models:PF1210, PF1214, PF1315, HD1110, HD1315

Maximum feed size:≤700 mm

Capacity:70-280 t/h

Weight:39-62 t

Portable sand maker is a professional equipment for making sand, also known as a wheeled vertical shaft impact crusher. It is used for fine crushing in the final stage of the crushing process, producing a precisely shaped cubic end product.

Matching method: Sand making machine + vibrating screening machine + conveyor belt + vehicle body

Common sand maker models:HVI0815, HVI0922, HVI1032

Maximum feed size:<45 mm

Capacity:60-585 t/h

Weight:31-49 t

Why choose GUOGAO Machinery’s portable crushers?

Portable rock crusher machines offer the following performance advantages:

Modular design: It features a modular and universal design, with each part being independent. The main unit can be replaced to switch between different models, reducing delivery time.

Unique integration: The fully automatic wheel mobile crushing station integrates feeding, crushing, screening, conveying, and other systems for seamless production.

Foundation-free installation: Vehicle-mounted mobile units do not require extensive concrete foundations, saving labor and reducing work site requirements.

Fully intelligent control: The equipment utilizes centralized PLC control and a touchscreen display to monitor machine operation at any time. Equipped with an independent electronic control system for easy operation.

Convenient mobility: With a length of 12-16 meters, the equipment is easily movable. The conveyor belt can retract and fold to minimize material transportation costs.

GUOGAO Machinery’s portable crusher machines can help you minimize your investment.

1. Cut transportation costs

A portable rock crusher can freely access the crushing site and move flexibly based on the progress of raw material mining. This allows for on-site crushing, resulting in savings of 50% to 70% in transportation costs.

2. Decrease labor expenses

With a small footprint, low labor intensity, and an intelligent control platform, only a few people are needed for the project, significantly reducing labor costs.

3. Lower spare parts expenses

By eliminating the need for extensive piling and large-scale foundations, the cost of spare parts is greatly reduced.

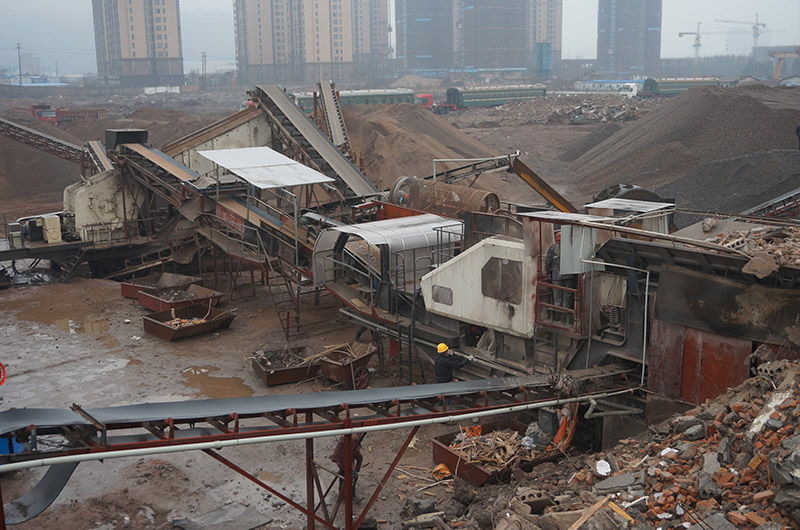

Successful cases of GUOGAO Machinery customers include the installation of a portable crusher for construction waste in the Philippines, with a capacity of 80-100 t/h.

Customer feedback:

“The portable construction waste crusher from GUOGAO Machinery ensured efficient production and consistently reduced operating costs.”

“I was delighted to observe the absence of dust throughout the entire production process. Additionally, its mobility resulted in decreased cement consumption costs, saving me a significant amount on overall production expenses.”

300 t/h limestone portable rock crusher in Australia