Heap Leaching is a process used to treat low-grade gold mines.

It has the following features:

– Simple process

– Easy operation

– Low energy consumption

– Cost-effective and efficient

– Scalable, with a maximum capacity of one million tons per day.

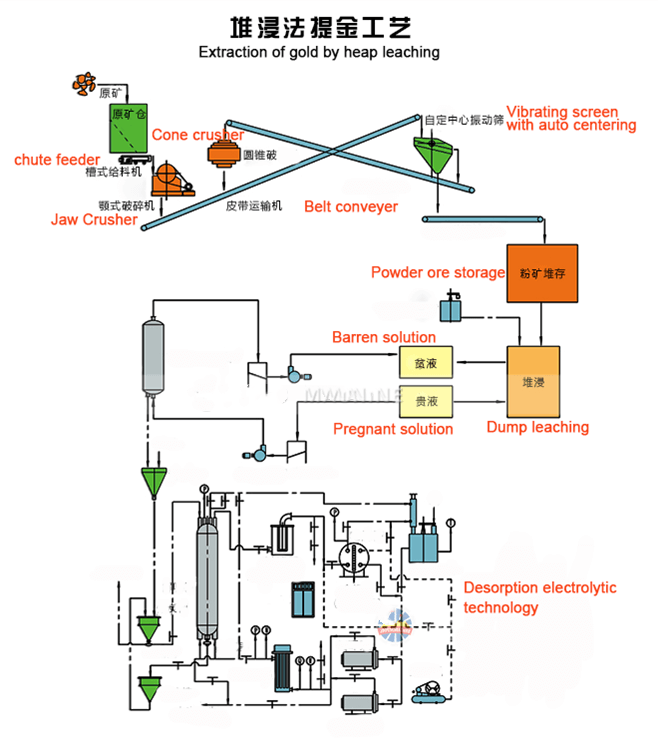

Technology Process

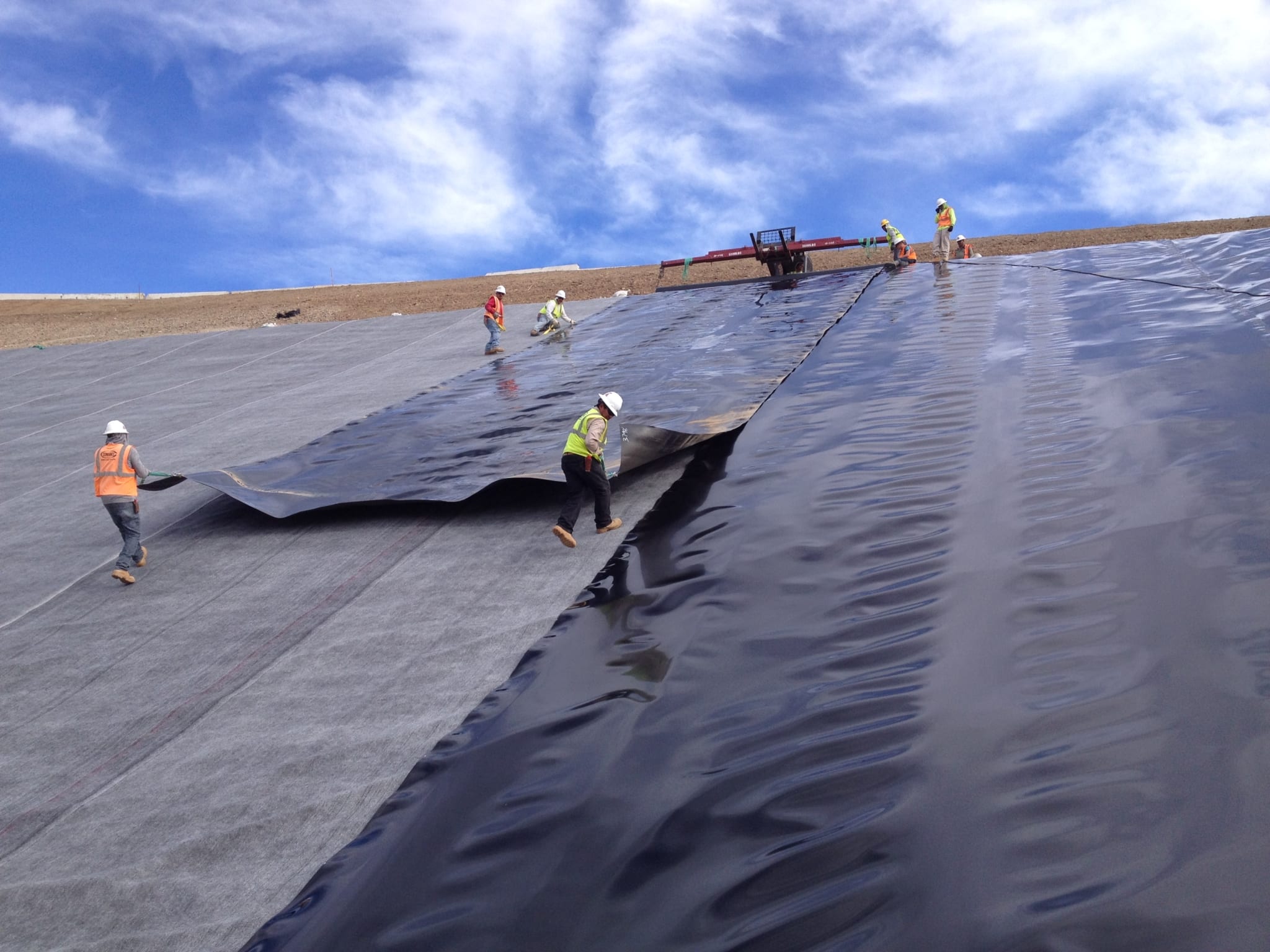

The heap leaching process involves the following steps: site preparation, ore pre-processing (crushing or production), concrete heap construction, spray leaching, disinfection, and recovery of gold from pregnant solution.

Raw Ore Processing

After being crushed by a jaw crusher and cone crusher, the raw ore particles become 30-50mm in size and are directly placed into concrete. Fine particles need to be produced first (converting them into coarse particles) before being transported to the concrete heap using a forklift truck.

Spray System

A spray system is installed above the heap. After reacting with cyanide solution, the pregnant solution seeps out from the heap and flows into a tank. From there, it infiltrates into an absorption column through a pump dedicated to pregnant solutions. The remaining solution is considered barren and returned to the spray system for recycling.

Desorption and Electrowinning

Under high temperature and pressure conditions during desorption and electrowinning processes, gold pulp is extracted. After smelting, it becomes gold bullion. The main equipment used in heap leaching includes jaw crushers, cone crushers, spray devices, desorption/electrowinning units,and smelting devices.

The primary equipment used in heap leaching consists of a jaw crusher, cone crusher, spray device, desorption and electrowinning system, smelting device, and more. Heap leaching is an industrial mining process that extracts precious metals, copper, uranium, and other compounds from ores. It employs a sequence of chemical reactions to absorb specific minerals and separate them from other soil materials.