Introduction: The hammer crusher is divided into two types: ordinary hammer crusher and ring hammer crusher. The ring hammer is commonly used in industries such as coal and coke. Ordinary hammer crushers are typically indicated by the prefix “PC” in English, while ring hammer crushers are indicated by the prefix “PCH”.

The hammer crusher possesses characteristics such as simple structure, high crushing ratio, and high production efficiency. It can be used for both dry and wet crushing, making it suitable for mining, cement, coal, metallurgy, building materials, highways, combustion departments.

Advantages:

The GUGAO PC hammer crusher’s hammer head is made of high manganese steel with high density and excellent wear resistance.

It has a high production capacity and produces uniform products; the desired discharge granularity can be adjusted according to customer requirements.

The machine body structure is sealed to solve issues related to dust pollution and ash leakage in the crushing workshop.

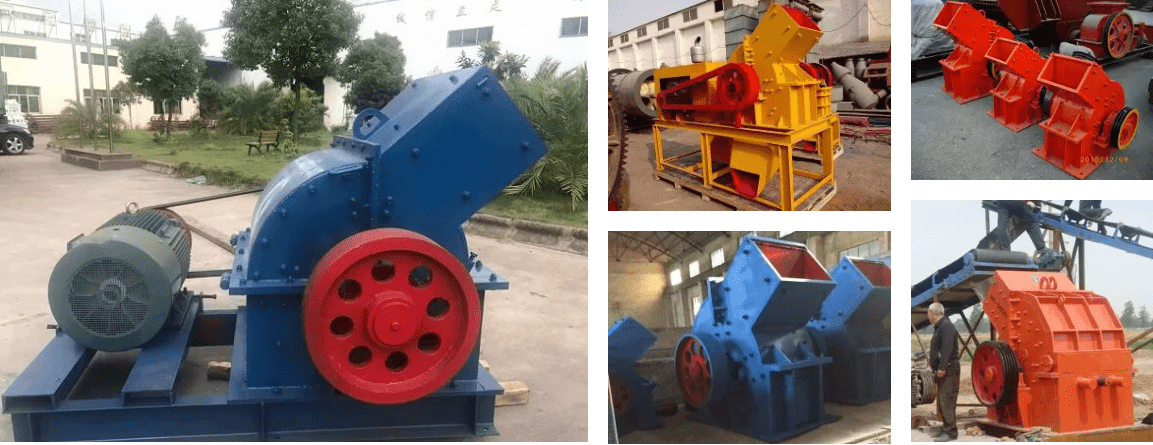

We offer customization options for fixed or mobile types of heavy-duty hammer crushers designed for large-scale crushing production lines.

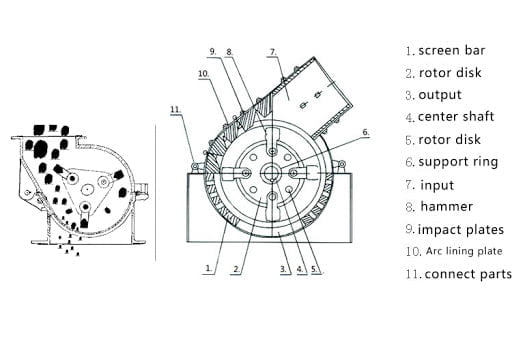

Working Principle Of Hammer Crusher

The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feed port and crushed by the impact, shearing and grinding of the high-speed hammer.

In the lower part of the rotor, there is a sieve plate, the particle size of the crushed material that is smaller than the size of the sieve hole is discharged through the sieve plate, and the coarse particle size larger than the sieve hole size is retained on the sieve plate to continue to be hit and grinded by the hammer, and finally passes the sieve plate out of the machine.

| Model | Speed | Feed size (mm) |

Out-put size (mm) |

Capacity (t/h) |

Weight (T) |

Power (kw) |

| PC-400×300 | 1450 | ≤40 | 0-10 | 1-3 | 0.8 | 11 |

| PC-600×400 | 1000 | ≤220 | 0-15 | 5-25 | 1.5 | 22 |

| PC-800×600 | 980 | ≤350 | 0-15 | 10-50 | 3.1 | 55 |

| PC-800×800 | 980 | ≤350 | 0-15 | 10-60 | 3.5 | 75 |

| PC-1000×800 | 1000 | ≤400 | 0-13 | 20-75 | 7.9 | 115 |

The main working part of a hammer breaker is the rotor, which consists of a main shaft, a disc, a pin, and a hammer (also known as a hammer head). The motor drives the rotor to rotate at high speed within the crushing cavity. Material is fed into the machine through the upper feed port and crushed by the high-speed impact, shearing, and grinding of the hammer. At the lower part of the rotor, there is a sieve plate. During crushing, particles smaller than the sieve hole size are discharged through it. Coarse particles larger than the sieve hole size remain on the sieve plate to be continuously impacted and ground by the hammer until they eventually pass through it and exit from the machine.