Diamond mining

Kimberlite is less resistant to weathering, so when it reaches the earth’s surface, natural forces like wind, rain, and fluviation erode it. Over thousands of years, eroded kimberlite carries rough diamonds downstream and enriches in the middle and lower reaches of rivers, seashores, and offshore continental areas, forming alluvial diamond deposits. The first diamond found in South Africa came from an alluvial deposit.

Alluvial mining is the world’s main source of diamonds, accounting for 40 percent of the world’s total diamond reserves but 70 percent of its production. Many primary mines are discovered by tracing back placer deposits.

1. River alluvial deposit

Based on their location, alluvial deposits can be divided into existing rivers (wet deposit mining) and ancient rivers (dry land diamond deposit mining).

Mining wet alluvial diamond deposits generally involves two methods: excavation dredging and river diversion.

Excavation method: A suction dredger equipped with a heavy-duty suction pump simultaneously pumps gravel, mud, ore while discharging water. The diamond ores are then picked out from this mixture. This excavation dredge method is used not only in river mines but also for marine diamond mines.

River diversion method: A large dam is built in an area to drain the river water and collect the layer of river gravel. Once collected, the gravel is hauled to the surface for processing as diamonds are often found within them.

2. Marine mining

Marine diamond mines can be categorized into three types: ancient beach mines, existing beach mines,and offshore mines that can be mined at depths of at least 200m.

The earliest form of marine mining was coastal diving where swimmers collected diamond-containing gravel from shallow sea bottoms. Nowadays with advancements in underwater mining technology specialized mine dredgers have been developed to carry out deep-sea operations for diamonds.

Namibia’s coast is well-known for its marine diamond minerals, and the Debmarine Namibia mining ship is currently the largest diamond mining ship in the world. It measures 170 meters long, 33 meters tall, has a crew of 98 members, and produces almost half of Debmarine Namibia’s total annual diamond production.

Diamond beneficiation process

Main factors influencing diamond processing flow:

1. Raw ore mineral composition and properties.

2. Disseminated grain size.

3. Ore argillization property.

4. Surrounding rock fragmentation.

5. Content of clay in raw ore.

6. Value minerals content.

7. Diamond processing plant scale.

8. Requirements of diamond concentrate.

Diamonds processing flow:

Stage 1 – Crushing: Once the diamond-bearing ore and gravel are collected, they are transported to a primary crusher where their size is reduced into smaller pieces or chunks measuring no larger than 150mm. A secondary crusher known as a roll-crusher may also be used to further reduce the size of the ore if necessary.In order to protect the integrity of the crystals during dissociation, a multi-stage crushing and sorting process is often employed to separate individual diamonds that have been separated from their host rocks.

Stage 2 – Scrubbing: In this stage, the ore is scrubbed to remove loose excess material and then screened.The material smaller than 1.5mm is discarded as it would be too costly to extract diamonds from such small pieces of ore.

Stage 3 – Cyclonic separation plant: During this stage, the diamond-bearing ore is mixed with a solution consisting of ferrosilicon powder and water which gives it a specific relative density.This solution is fed into a cyclone which tumbles the material and causes separation.Materials with high density sink to bottom forming layers rich in diamonds known as concentrates.

Stage 4 – Recovery: Here,the diamond-rich concentrate undergoes processes involving magnetic susceptibility, X-ray luminescence, and crystallographic laser fluorescence.These processes are designed to separate the rough diamonds from any other heavy density materials collected by the cyclonic separation plant.For example, diamond’s fluorescence when exposed to an X-ray is detected by sensors which then trigger a blast of air that separates the diamond and directs it into a collection box.

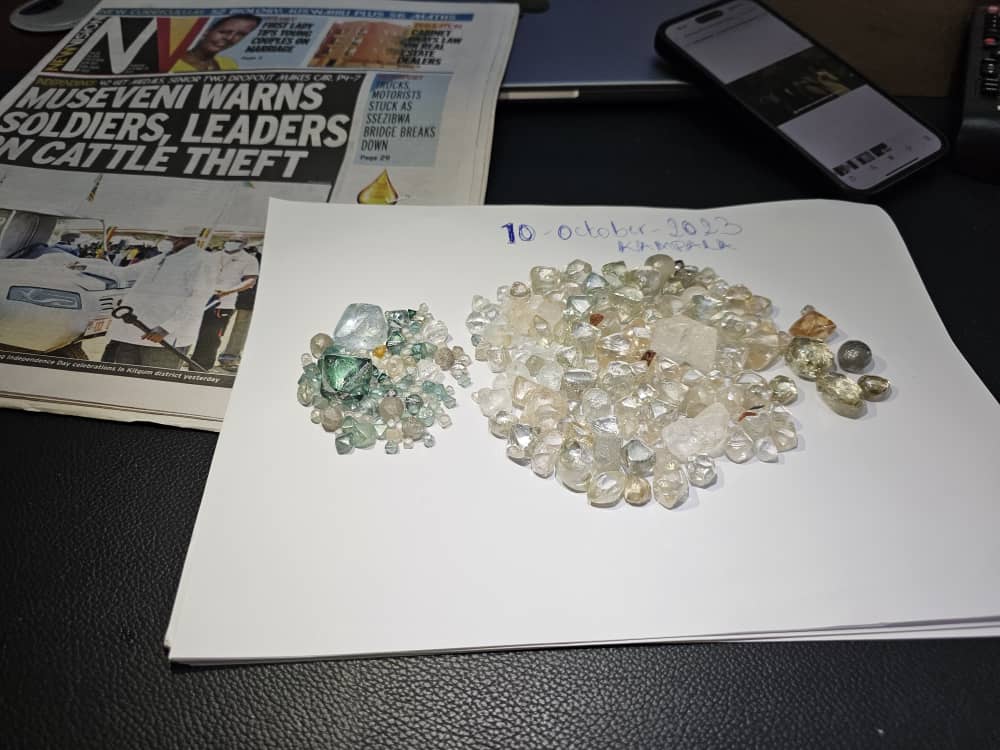

Stage 5 – Cleaning, weighing, and packaging: The diamonds collected in the recovery process are cleaned in an acid solution,washed, weighed,and packaged in sealed containers for transportation. In accordance with the Kimberley Process,the containers are sealed with tamper-resistant seals numbered on-site,and a certificate of origin is issued.