Cathode copper production line

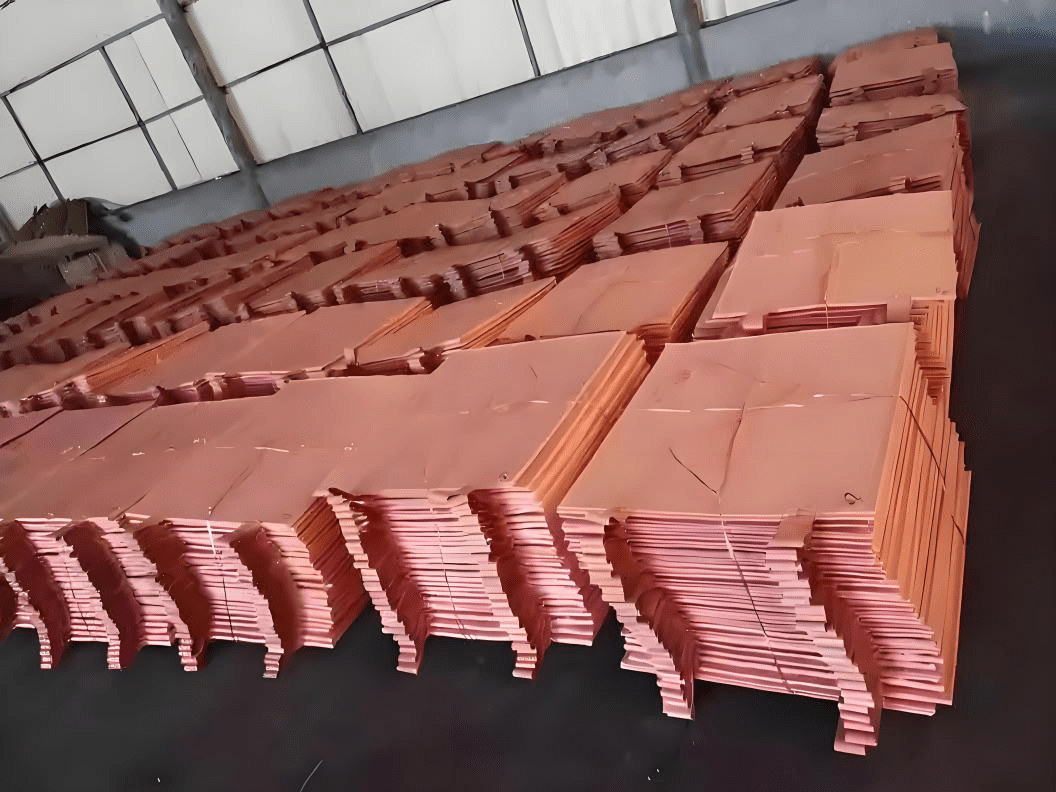

In contemporary manufacturing, copper electrolysis plays a crucial role in creating high-purity copper cathode plates. These plates are extensively utilized in electrical engineering, electronics, and various industrial sectors due to their superior electrical conductivity and minimal impurity content. Guogao will present the technology and equipment associated with the production line for copper electrolytic cathode plates.

The production line for copper electrolytic cathode plates primarily includes an anode plate forming unit, an electrolyzer, a cathode plate stripping unit, a residual electrode cleaning unit, a fully automated traveling car, and a traveling car guide frame. These components work in unison to ensure an efficient and continuous production process.

In the industry, this process is conducted on a large scale. The production of electrolytic copper takes place in large electrolytic tanks filled with a copper electrolytic solution. Although even the most effective chemical methods cannot eliminate all impurities from copper, electrolytic refining can achieve a purity level of 99.99% (regardless of the method used to extract copper from its ore, the final purification is done through electrolysis).

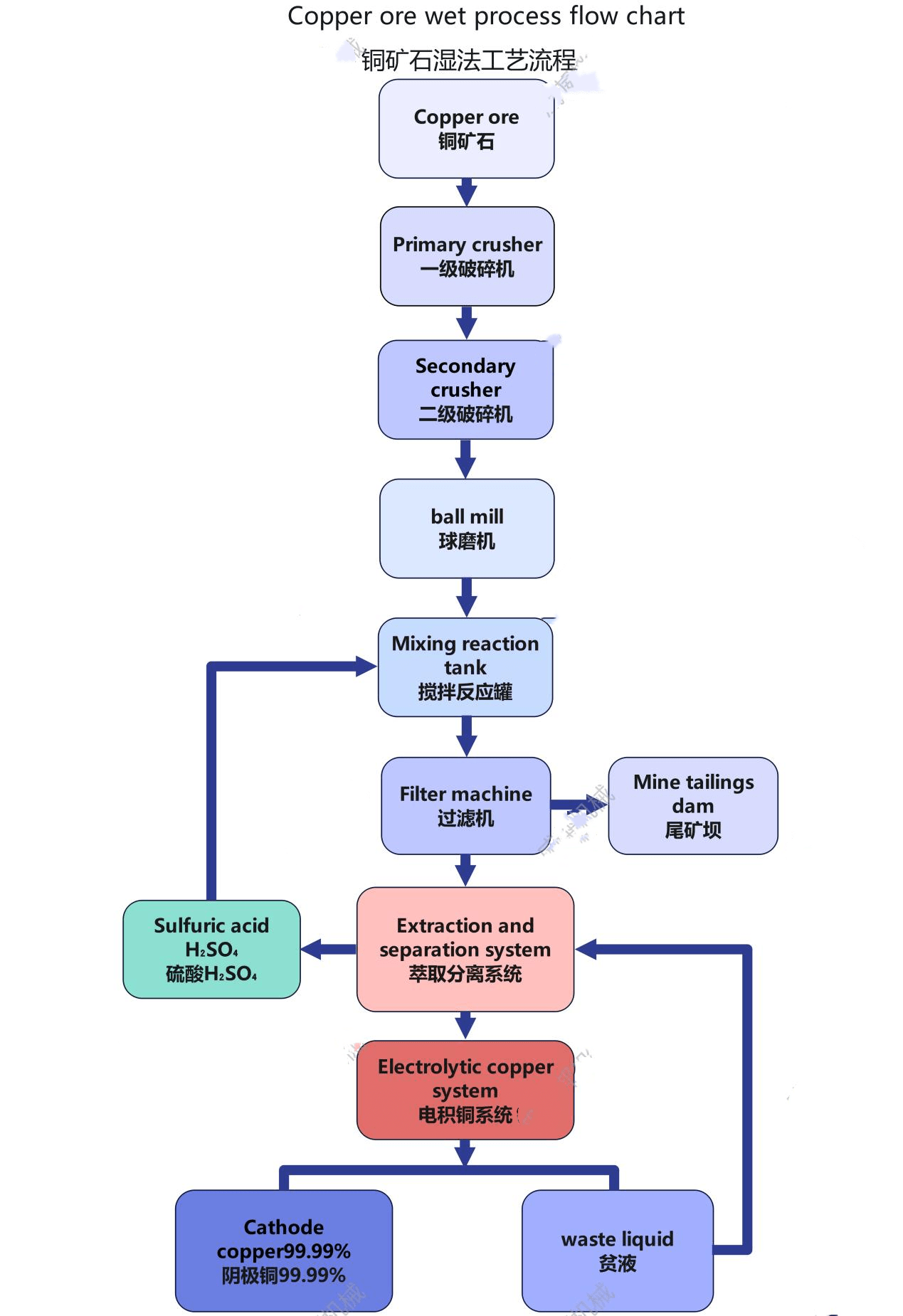

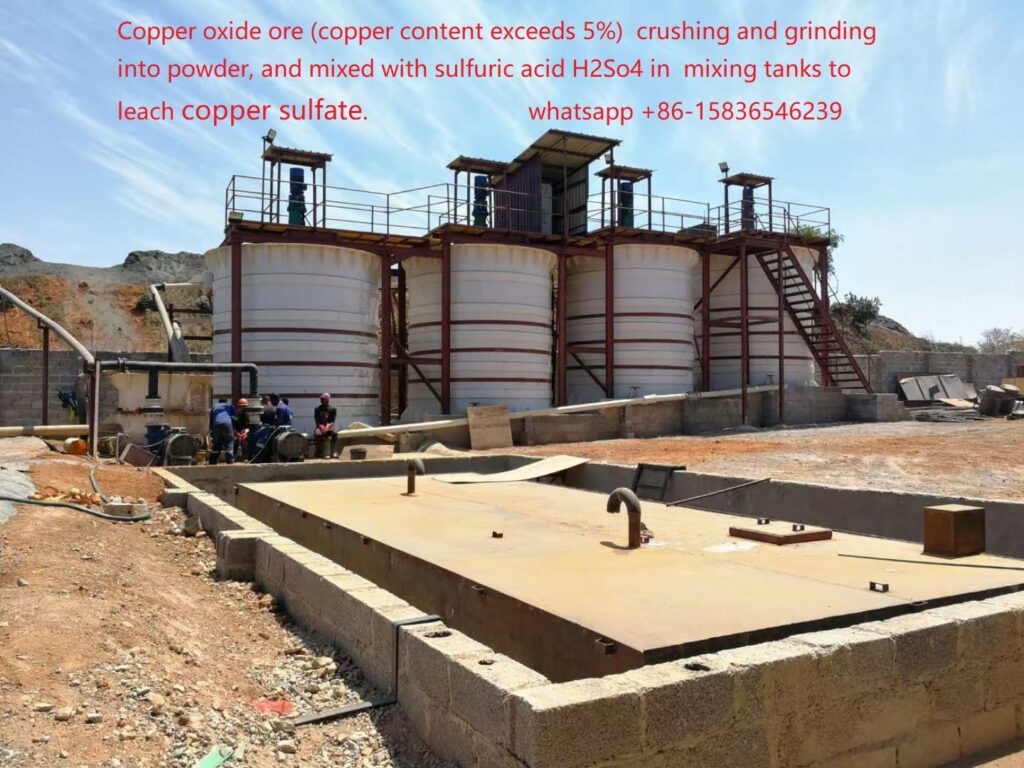

1 step, Cruhsing&Grinding copper oxide (3% Cu Above) to powder

2step, Copper oxide powder and sulfuric acid are mixed and extracted to form copper sulfate.

3step, Copper sulfate is put into the electrode plate.

4step, The electrolytic reaction produces cathode copper.

5step, The sulfuric acid is recovered and recycled.