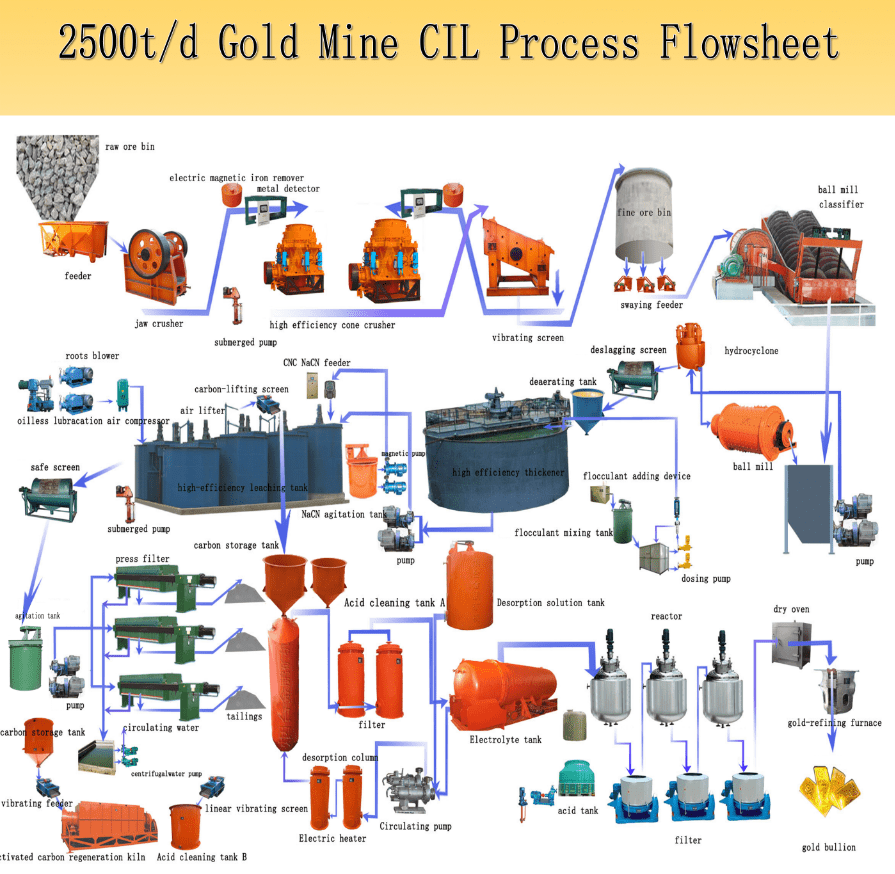

【Process Introduction】

The Gold CIL (Carbon in Leach) Process is a highly efficient method for extracting and recovering gold from its ore. By simultaneously cyaniding and carbon leaching crushed gold ore slurry, the CIL process reduces the cost of gold mining operations and increases the recovery rate to an impressive 99%. It has become the preferred choice for modern gold mining and beneficiation plant design.

【Application】

CIL is primarily used for processing high-grade gold ores (above 1g/t) as well as those with a large volume of associated minerals such as silver, platinum, copper, etc. The CIL process demonstrates superior performance in extracting these minerals simultaneously. Additionally, GUOGAO Dressing Test Center can assist you with component testing of your ores.

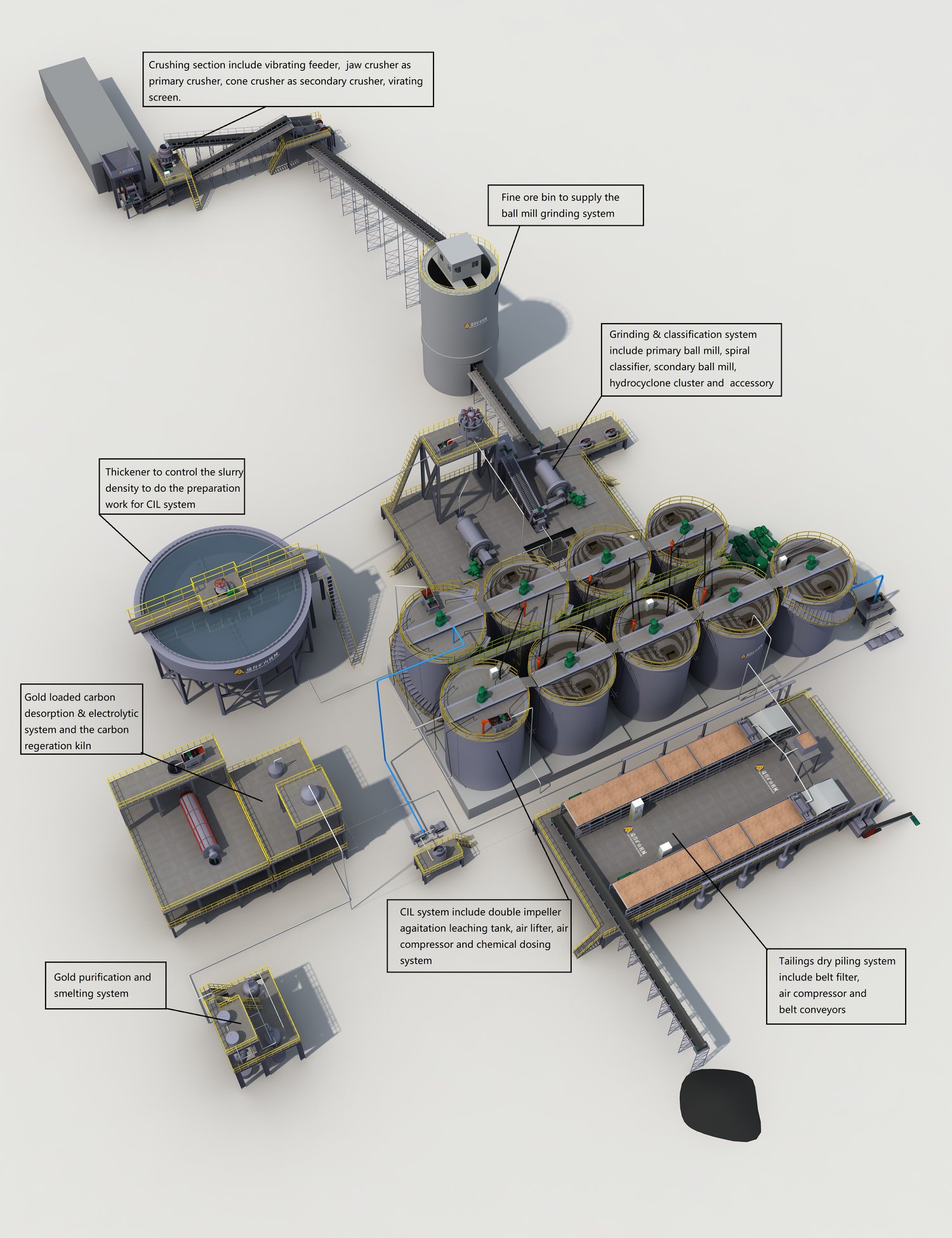

【Flow Design Equipments】

Leaching Agitation Tanks

After crushing and comminution, add the gold ore slurry to 9 leaching agitation tanks. Pour cyanide solution into the first 2 tanks and activated carbon into the following 7 tanks for reverse-absorption process. This design reduces the time that gold stays in the cyanide pregnant solution and allows for earlier recovery of gold, resulting in a faster return on investment compared to other designs.

Filter Press and Vibrating Screen are required for the reverse-transmission process of gold ore slurry.

Press Filter

GUOGAO has designed a system that minimizes carbon loss during transmission. It reduces gold losses and makes maintenance of the processing line easier.

After carbon leaching and elution of gold, NaCN and NaOH solutions are used at high temperatures to remove gold from loaded carbon. The loaded solution then passes through an electrowinning cell where metals attach to cathodes.

Desorption Electrolysis System

GUOGAO’s Desorption Electrolysis System successfully combines these steps into one processing unit, resulting in highly pure gold and other valuable metals being obtained through this process.

【What We Do】

With a track record dating back to 1997, GUOGAO has established itself as a reputable leader in the field of mineral processing technology. By setting up over 50+ gold CIL plants worldwide, we have consistently delivered substantial profits to mine owners. Our comprehensive services include Whole Line Plant & Design Personnel Training, Equipment Procurement, and Construction from ore extraction to pure gold production. For more information about our EPC Service

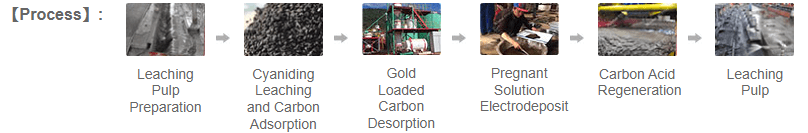

1. Leaching Pulp Preparation

Equipment: GUOGAO Efficient Leaching Agitation Tank

Procedure: Add the gold ore slurry to 9 leaching agitation tanks. Pour cyanide solution into the first 2 tanks and activate carbon in the remaining 7 tanks for reverse-absorption process (number of tanks depends on capacity size).

Advantages of leaching pulp in GUOGAO gold CIL process:

Significantly reduces number of leaching tanks; Shortens time for gold to stay in cyanide pregnant solution; Reduces capital backlog during gold staying process, enabling quick acquisition of gold and fast capital return.

2.Cyanide Leaching and Carbon Adsorption

Equipment: Washing Thickener

Material: GUOGAO special coconut shell activated carbon

Material features: GUOGAO special coconut shell activated carbon has small pores, high reactivity, wear resistance, and renewability. It increases the adsorption speed by 30%.

Advantages of carbon adsorption in GUOGAO gold CIL process:

GUOGAO special coconut shell activated carbon greatly improves gold recovery from associated metals, significantly enhancing economic benefits and production efficiency. The continuous discharging feature of GUOGAO washing thickener reduces multiple cycles of hydrothermal gold recycling at an early stage. It extends pulp concentration time and increases leaching rate. Additionally, GUOGAO washing thickener achieves countercurrent washing with a large volume and high efficiency.

3.Carbon Acid Regeneration

Equipment: GUOGAO Hydraulic Filter Press, High Frequency Dewatering Screen

Advantages of carbon acid regeneration in the GUOGAO gold CIL process:

– Minimizes gold losses during transmission, reducing both processing line maintenance and gold losses.

4.Pulp Agitation

Equipment: GUOGAO Central Air Lifter

Advantages of pulp agitation in the GUOGAO gold CIL process:

– Fast pulp conveyance, resulting in shorter cycles.

– 70% reduction in power consumption.

– Even suspension of solid materials.

– Low wear on activated carbon.

– High rate of gold recovery.

5.Gold Loaded Carbon Desorption

Equipment: GUOGAO Desorption Electrolysis System

Advantages of GUOGAO’s desorption electrolysis system in the gold CIL process:

The system utilizes high-temperature and high-pressure desorption (150℃, 0.5Mpa) to efficiently desorb 99% of gold within 2-6 hours. The pregnant solution contains high concentrations of gold and silver cyanide complex ions, with fewer impurity ions. By employing GUOGAO’s efficient, low-powered, and fast desorption electrolysis system, solid gold with high purity can be obtained safely and economically.

Application

The gold CIL process is mainly used for low-grade oxide ore with silver, as it is more economical and beneficial.

Process introduction carbon in leach gold processing

The CIL process mainly includes decontamination, pre-leaching concentration, leaching and adsorption, desorption and electrowinning, hydrometallurgy, activated carbon regeneration, tailings filtration, wastewater treatment, etc.

1. Decontaminate impurities: Remove impurities such as fine particles before cyanide adsorption to prevent them from adsorbing gold from the slurry or blocking the carbon separator.

2. Pre-leaching concentration: Usually dewater the slurry through a thickener before leaching to achieve a suitable leaching concentration. The concentration can affect the leaching time and the floatation of activated carbon.

3. Leaching and adsorption: Transfer the decontaminated and concentrated slurry into high-efficiency leaching tanks (usually 5-8 tanks). Add cyanide solution to the first two tanks and add activated carbon to the remaining five tanks. The activated carbon absorbs gold particles to become loaded gold carbon which is then separated from the slurry using an air lifter and lifting screen.

4. Desorption and electrowinning: Desorb gold from activated carbon in a closed system under high temperature and pressure conditions. Electrowin liquid gold. Main equipment includes desorption column, acid tank heater filter ,desorption tank ,electrowinning tank etc .

5.Smelting : After acid washing and decontamination,gold ingot will be smelted . Using hydrometallurgical method,the purity of gold could reach 99.99%.

6.Application of regenerated activated carbon : Acid washes are performed on desorbed activated carbons to remove accumulated carbonate.After multiple uses,the carbons need heating activation for regeneration.Then they can be recycled.Main equipment includes regenerated tank ,water quenching tank ,fine carbon separation screen.

Tips: You can bookmark this webpage or search for it on Google using the following keywords: carbon in leach (CIL), gold recovery process, crushing gold ore, CIL mining, sale of gold tailings, CIP equipment, gold crusher machine, carbon in pulp (CIP) process, gold recovery from mine tailings, CIP gold process, carbon in leach for gold extraction, carbon in pulp for gold extraction, crusher for gold mining operations, CIL plant operation and maintenance procedures for extracting gold through the carbon-in-leach method. Additionally: operating a CIP plant to extract and recover dissolved precious metals such as silver and copper; heap leaching of cobalt-bearing ores; cyanide-based methods used in iron ore processing; crushing rocks containing high-grade deposits of precious metals like platinum and palladium; trading activities related to the extraction of valuable minerals from mines located within Gabon’s borders; establishing a facility dedicated to recovering precious metals from low-grade ores using bioleaching techniques; constructing a mineral processing plant capable of handling various types of raw materials including rock containing significant amounts of manganese oxide.