A ball mill, also known as a ball milling machine, mineral grinding mill, or ore grinding mill, is a grinder that uses balls to reduce the size of materials for processes such as mineral dressing, cement plants, fertilizer plants, etc.

How does a ball mill work?

A ball mill operates based on the principles of impact and attrition.

Add approximately 33% balls into the ball drum. The specific percentage can vary within the range of 30%-45%. As the ball mill rotates, the balls adhere to the inner surface of the drum due to centrifugal force and are lifted on the rising side. When reaching a certain angle, gravity overcomes centrifugal force causing balls to cascade down towards the centerline of the ball mill. This results in impact (balls colliding with ore) and attrition (ore rubbing against other pieces of ore and milling balls), reducing it to the desired size.

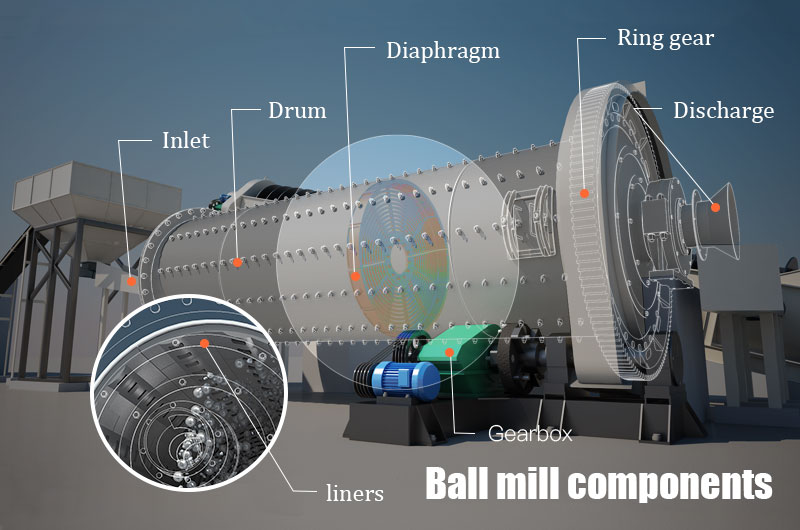

Important parts of a ball mill:

Inlet – Crushed ore is fed into the ball mill through the inlet.

Discharge – Reduced feed exits the mill through the discharge outlet.

Drum – The drum is the cylindrical casing of the ball mill. It is lined with armor (also known as liners) to protect the steel shell from abrasion. There are various types of liners, such as galvanized iron plates, manganese liners, rubber liners, etc. Choose an appropriate liner based on factors like grinding material, output, budget, etc.

Ring Gear – A gear ring installed on the outer periphery of the drum.

Electric Motor – A motor used to rotate the drum. The motor drive train connects to a gearbox and then to a ring gear. Usually equipped with a variable speed drive (VSD) to control the RPM of the ball mill.

Gearbox – Used for speed reduction between the motor and ball mill.

Balls – Also referred to as ball mill media. They can be made of steel balls, ceramic balls, manganese alloy steel balls, etc. The selection of grinding media depends on what material needs to be ground. Ball size also plays an important role in achieving higher grinding efficiency; therefore choose appropriate types and sizes of balls in ratios that include large, medium, and small ones.

Bearings – Small ball mills use anti-friction cylindrical roller bearings while large ones use trunnion bearings and hydrostatic bearings.

Ball mill types

The ball mill can be divided into different types based on the process conditions:

1. Wet ball mill: It grinds the material into a slurry with a certain concentration (usually 60-70%). Wet ball mills are mainly used for mineral beneficiation and typically have single-chamber structures.

2. Dry ball mill: It grinds the material into qualified mineral powder. Dry ball mills are suitable for grinding hard materials such as silica sand, quartz stone, marble, and cement clinker.

The difference between dry ball milling and wet ball milling lies in whether water is added. Adding water makes it wet.

Based on the structure, the ball mill can be categorized as follows:

1. Grid-type ball mill: When a product with a fineness of 0.2-0.3mm and uniformity is required, it is preferable to use a grid-type ball mill.

– It can discharge qualified products promptly, reduce ore over-grinding, and improve grinding efficiency.

– Grid-type ball mills are often used in first-stage grinding systems.

2. Overflow ball mill: This type of ball mill provides fine grinding effects and is suitable for the second stage of two-stage grinding processes.

– The feed particle size is generally less than 0.2mm.

– Its capacity is approximately 15% lower than that of grid-type ball mills with similar specifications due to reduced amount of grinding media.

Mills can also be classified based on their grinding media:

1. Ball mill: Grinding media consists of cast steel balls or forged steel balls.

2. Rod Mill: Grinding media includes cylpebs and rods.

3.Ceramic Ball Mill: The medium used for grinding is ceramic balls.

Lastly, based on the length-to-diameter ratio of the drum:

1.Ball Mill:A typical drum length in this case would be either equal to or 1.5 times greater than the drum diameter.

2.Tube Mill: A mill with a length-to-diameter ratio greater than 1.5 is referred to as a tube mill.

Ball mill application

The ball mill machine is typically used in the comminution stage as a grinding mill to reduce the size of the feed. It can be used for both primary and secondary grinding. In primary grinding, it receives feed from crushers such as jaw crushers. If the ball mill is used for secondary grinding, it receives feed from other grinders, such as rod mills or SAG mills.

Now that we understand that the ball mill is an efficient grinder, what materials can it grind?

Ball mill in mining and mineral processing

Ball mill grinders are commonly employed for grinding various ores, including copper ore, gold ore, iron ore, lead-zinc ore, nickel ore, manganese ore, chrome ore, lithium ore, etc. The role of the ball mill in ore processing is to reduce the size of the particles so that valuable minerals can be extracted more efficiently.

It is also utilized for grinding bentonite, kaolin, barite calcite dolomite mica talc etc.

In terms of mineral processing applications ,ball mills often work alongside other equipment such as crushers flotation machines magnetic separators gravity separation machines.

Ball mill in cement grinding

The main objective of cement ball mills is to grind clinker and gypsum into a finer powder to produce final cement products.

In addition to clinker and gypsum grinding ,ball mills can also be used for grinding other materials like slag pozzolan dolomite fly ash etc.These materials are added to improve properties like strength and durability.

Ball Mill in fertilizer industry

Ball Mills are employed for fine powdering raw materials like phosphate rock limestone and other minerals.They are also utilized for material mixing.For example,a Ball Mill may be used to mix urea with ammonium nitrate creating a fertilizer product

Additionally,Ball Mills efficiently grind coal coke construction materials glass ceramics quartz stone silica sand marble etc

Apart from Grinding,Ball Mill Machines find usage in Mixing Blending Dispersing materials and are popular in Chemical,Pharmaceutical,Food Industries as well as Mining and Mineral Processing.

Ball mill manufacturer: Fote, the best choice for you

With over 40 years of experience in ball mill technology, Fote can manufacture, supply, and export durable and robust ball mill grinders at a lower cost.

Long lifespan and minimal maintenance

To help maximize your business potential, we have designed our ball mills with long-term operation in mind, requiring minimal maintenance.

Our sturdy design ensures extended service life and reduced maintenance needs. Therefore, wearable parts of Fote ball mills are made from high-quality materials to prolong their lifespan. This includes the shell of the ball mill drums, linear components, grinding medium, among others.

Efficient operation through automation

Fote engineers are ready to assist you with circuit control design as well as start-up, operation, and optimization of your milling plant. Automatic operation saves power consumption while increasing capacity by minimizing grinding media and liner wear.

Effective ball bill grinding technology

The screw at the feeding end rotates in the opposite direction to the screw at the discharging end. This design guarantees even feeding speed and uniform discharging. Additionally, an iron remover can be equipped according to your specific requirements.

Adequate parts supply and excellent service.

The ball mills produced by Fote Machinery minimize wear during operation due to exceptional casting processes and heat-treating technologies.

The grinding balls made from high manganese steel exhibit good toughness and manufacturability at a low price point.

Ball mill accessories include big gear wheels,pinions,hollow shafts,rings gears,big ring gears ,steel balls ,compartment boards ,transmissions,bearings,end linings,and more .

Sufficient component supply aims to minimize equipment repair or replacement timeframes.

Fast delivery speed

Even during Covid-19 pandemic restrictions,your products will be delivered promptly as long as trade permission is granted in your country

Below is a list of some customer countries/regions along with their fastest shipping method(s)and approximate delivery times, based on the actual situation.

Parameter

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | As per process conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | As per process conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | As per process conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |

If you are interested in ordering, please contact us