Advantages

The mercury amalgamation machine, also known as a gold mercury amalgamator or mercury amalgamation drum, is commonly used in small and medium-sized placer gold panning to extract gold from placer gold.

The mercury mixing cylinder is widely used in gold concentrators as internal mercury mixing equipment. It effectively treats the gold-bearing heavy sand of placer gold mines and the gravity separation gold concentrate of vein gold mines. The recovery rate of mixed mercury-gold in the mixing cylinder can exceed 98%, making it an efficient internal mixing equipment.

Features

High recovery ratio exceeding 98% with low loss rate of mercury.

Newly designed automatic gold amalgamator driven by a motor.

Stepper motor for easier operation.

Stainless iron tank for extended service life and conservation of mercury.

Neat and clean structure design.

Easy to carry and remove.

Highly efficient with recyclable Hg usage.

Simple operation, high efficiency, better results when combined with a mercury amalgamating shaker.

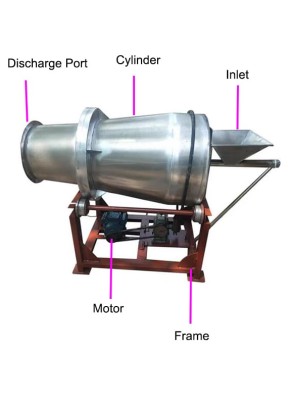

Product Structure

【Mercury Amalgamator Structure】

The barrel is usually made of stainless steel. Its inner and outer are all polished. Thus no dead space & easy to rinse thoroughly. It contains 3 ports, partly for feeding, maintenance, and discharging.

【Mercury Amalgamator Working Principle】

The mercury amalgamation cylinder is tilted at a certain angle to the horizontal. The cylinder has a feed port, and a mesh plate separates the lower end from the amalgam storage chamber. The mercury paste storage room also has an angle with the horizontal. There is an automatic ore separation valve at the lower end and an ore discharge port at a certain height on the end face. Pipes are used to connect the cylinders quickly. A hydraulic mercury capture and recovery device is also installed at the tailings discharge end of the two amalgam storage rooms. Microcomputer time control is adopted to control the inlet and outlet solenoid valves according to predetermined procedures to realize continuous and fully automatic mercury amalgamation operations. It is an ideal equipment for gold selection.

Technical Parameters

| Model | Capacity (t/h) | Feeding Size (mm) | Motor Power(kw) | Reducer | Weight (kg) | Size L*W*H (mm) |

| 0.5 | 0.5 | ≤15 | 0.75kw *4 Level | 60-10 | 105 | 1000*1000*650 |

| 1 | 1 | ≤15 | 1.5kw *4 Level | 23-1.5 | 250 | 1400*1500*1000 |

| 2 | 2 | ≤15 | 1.5kw *4 Level | 23-1.5 | 300 | 1500*1800*1000 |