Alluvial and rock gold beneficiation methods are crucial for maximizing the extraction and recovery of gold from different ores. These methods utilize physical, chemical, and mechanical processes to separate gold particles from surrounding impurities.

Alluvial Gold Beneficiation Methods

Placer or alluvial gold is commonly found as fine particles in geological settings like rivers, river beds, gravel, and dunes. Due to its high density, these gold particles usually settle at the sediment’s bottom. Alluvial gold tends to be coarse with different particle sizes and can be easily separated using physical techniques such as gravity beneficiation, screening, and washing.

Gravity Separation: Alluvial gold, which is generally heavier, can be separated using gravity separation equipment such as shaking tables, spiral chutes, jig separators, centrifugal concentrators, etc. These devices separate placer gold from other impurities.

Flotation: If alluvial gold contains sulfide minerals, flotation can be employed. In this process, alluvial gold is immersed in water containing a foaming agent and then the gold particles are separated from impurities by the action of bubbles.

Screening and Washing: Alluvial gold is typically found in river beds, river banks or sand dunes. The most common method involves collecting placer gold deposited on river beds through open pit mining. This usually entails using tools like gold pans, skips or sand separators to screen, wash and settle the gold particles.

Cyanidation: Certain chemical methods can extract gold from alluvial deposits. However, these methods require specialized knowledge and equipment and must be carried out with caution.

Rock Gold Beneficiation Methods

Rock gold is a type of ore that is found in hard rock formations, existing as fine grains, tiny particles, or refinements. It is commonly discovered within veins, gangue, and sulfide minerals. The attachment between gold particles and rocks is highly robust, necessitating more intricate extraction techniques. These methods typically involve a combination of chemical and physical processes such as crushing, grinding, cyanide leaching, oxide ore leaching, carbon leaching, etc. This complexity arises from the fact that the gold particles in rock gold are usually smaller and require multiple processing steps for complete extraction.

Crushing and Grinding: Rock gold is often found in hard rock formations, requiring the initial step of grinding and breaking the rock to release the gold ore.

Gravity separation: Similar to placer gold, rock gold can also be separated initially through gravity separation. This can be accomplished using equipment such as vibration tables, centrifuges, spiral chutes, and others.

Flotation: The flotation method is applicable when the rock gold ore contains sulfide minerals. It typically involves grinding the rock gold ore and then using flotation equipment to separate the gold ore.

Cyanidation method: Cyanidation can also be used for rock gold ores that contain sulfur minerals. This process entails exposing the gold ore to a cyanide solution in order to dissolve the gold, followed by extracting it from the solution through electrolysis or adsorption processes.

Carbon leaching (CIP): Gold carbon-in-pulp is a commonly employed extraction method that involves contacting activated carbon with gold, adsorbing it from a solution containing dissolved gold onto the carbon material, and subsequently extracting the capturedgold fromthe carbon.

Gold Beneficiation Plant

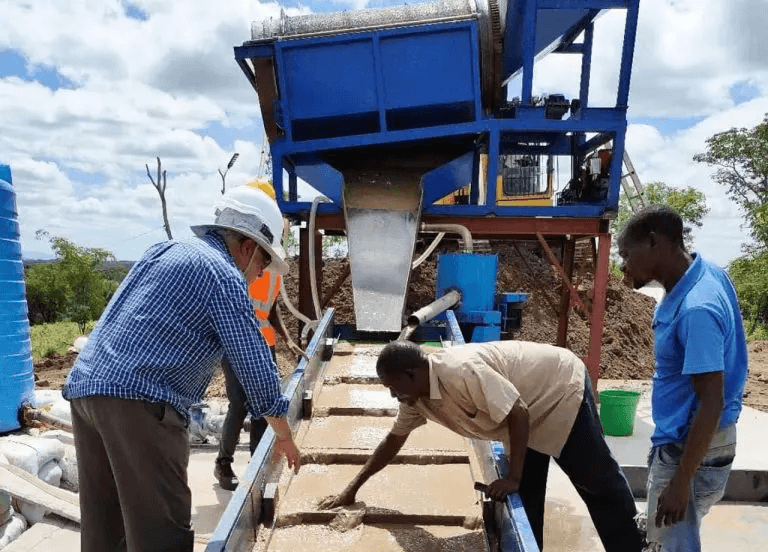

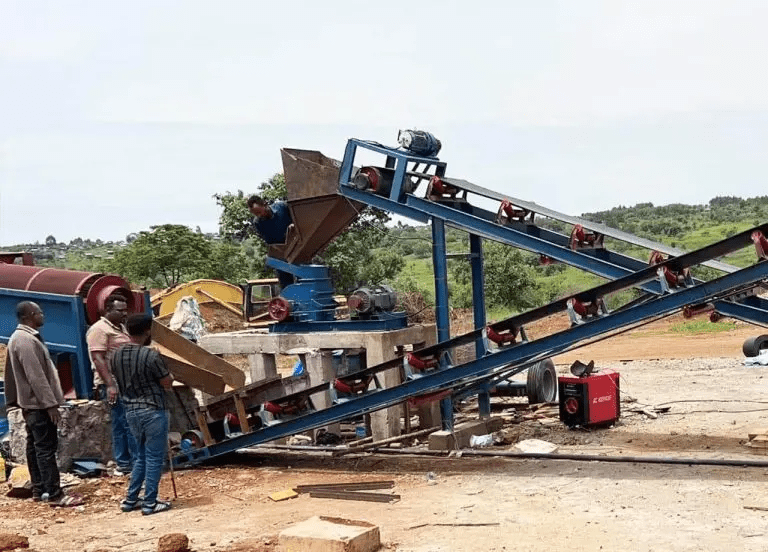

50 TPH Alluvial Gold And Rock Gold Processing Plant at CONGO DRC

If you are interested in ordering, please contact us

PHONE NUMBER

+86-15836546239(WhatsApp)