Introduction: The gold centrifugal concentrator operates at high speed, generating a strong “G” force that can separate small gravity recovery gold (less than 50 microns). It can also recover the tailings of gold, chromite, scheelite, and other heavy minerals to maximize the use of mineral concentrate. Due to its low cost and excellent recovery of fine minerals, the application of centrifugal concentrators is increasingly important worldwide.

Advantages:

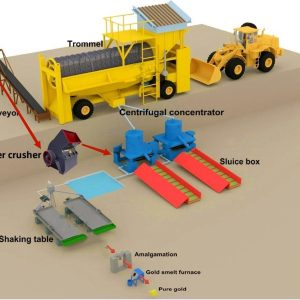

Often used in alluvial gold processing plants in conjunction with gold trommel scrubbers, trommel screens, shaking tables, sluice boxes, and other beneficiation equipment.

Efficiently recovers fine gold from alluvial gold ores at a low cost.

Provides continuous output of concentrate and tailings with high yield, recovery rate, and enrichment ratio.

Features low production cost, good wear resistance of parts, simple maintenance,

compact design,

small footprint,

and easy integration into existing concentrator processes.

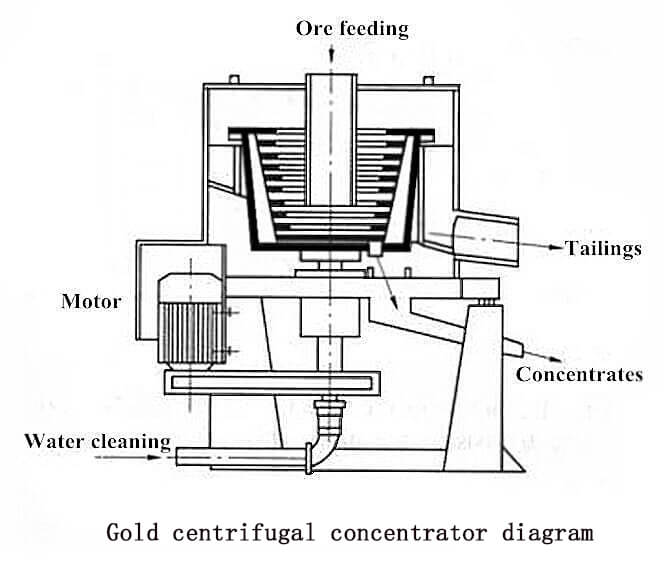

Working Principle Of Centrifugal Concentrator:

The gold centrifugal concentrator is a device that enhances gravity separation. The feed slurry enters a rotating drum where the impeller creates a high-gradient centrifugal field. Ore particles flow along the inner wall of the rotor and continuously layer and deposit on the smooth interior surface.

Lighter particles outside the bed are removed from the rotor assembly due to their lower specific gravity or smaller size. Heavy particles remain in the concentration zone where they are cleaned using fluidized water. A spinning rotor throws feed into the center against the walls of a bowl. Light and fine particles are carried out with tailings while heavy and coarse particles are collected and removed. These units can operate as batch or continuous systems industrially by intermittently opening pores to collect concentrate.

|

Model

|

Capacity (t/hr)

|

Feeding Size(mm)

|

Feeding Density(%)

|

Power Requirement

(kw) |

Cone Rotate Speed

|

Water Required(m3/h)

|

Dimension(mm)

|

|

STLB20

|

<0.6

|

<3.0

|

0-50

|

0.75

|

800

|

2-3

|

800*560*710

|

|

STLB30

|

2.0-3.0

|

<3.0

|

0-50

|

1.5

|

600

|

3-5

|

1280*1030*1135

|

|

STLB60

|

8-12

|

<5.0

|

0-50

|

4

|

460

|

8-12

|

1850*1550*1600

|

|

STLB80

|

40-45

|

<6.0

|

0-50

|

11

|

400

|

30-36

|

2300*1800*2200

|

|

STLB100

|

80-120

|

<6.0

|

0-50

|

18.5

|

360

|

60-80

|

2400*2400*2250

|