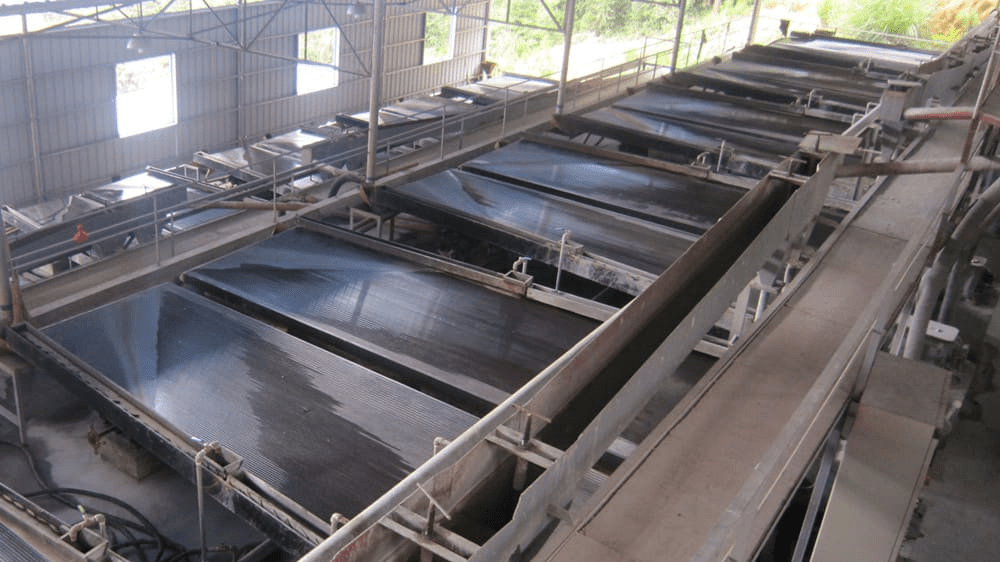

A 6-S shaking table, also referred to as a 6S shaker table, is utilized in mineral processing and various industries for gravity separation of materials based on density and particle size. It employs reciprocating motion to separate materials according to their density. The table surface contains riffles or grooves along with a shaking mechanism that generates vibrations. In the following section, we will address nine frequently asked questions about the 6-S shaking table, covering topics such as adjusting stroke and stroke times, determining the lateral slope of the bed surface and its relation to flushing water quantity, managing feeding concentration and volume in relation to processing capacity, as well as installation and debugging procedures for the shaking table.

- How to Adjust Stroke?

When you rotate the stroke adjustment handwheel clockwise, the adjustment slider rises and reduces the stroke. When you rotate it counterclockwise, the adjustment slider falls and increases the stroke. Once you have determined the stroke adjustment, tighten the fixing bolt at the bottom of the stroke handheel. Remember to adjust the spring adjusting bolt at the rear of gearbox accordingly when adjusting stroke to prevent damage caused by loose or tight parts.

- How to Adjust Stroke Times?

Replace motor pulley.

- How to Match Stroke And Stroke?

Match large strokes with small strokes and small strokes with large strokes. For coarse-grained ore processing, a thick bed requires a larger stroke but fewer strokes. Conversely, for fines and slimes processing, a smaller bed thickness requires a smaller stroke but more strokes.

- What is The Relationship Between The Lateral Slope of The Bed And The Amount of Flushing Water?

Increasing both lateral slope and flushing water amount can accelerate lateral movement speed of ore particles; however, increasing flushing water amount also enhances selective separation effect. Generally, roughing or sweeping operations adopt “big slope and small water,” while selection operations adopt “small slope and large water.”

5.What is The Relationship Between Feeding Concentration, Feeding Volume And Processing Capacity?

Feeding volume affects pulp flow rate on bed surface: increased feed volume leads to decreased concentrate recovery and increased tailings losses.

Higher feeding concentration results in thicker solid material layer which slows down stratification speed leading to lower concentrate recovery rate; more metals enter medium ore.

Controlling feed volume during production while appropriately increasing feeding concentration can improve processing capacity; however, maintaining uniformity in feeding concentration,volume,and flushing water volume is crucial as it directly impacts distribution.

6.How to Install 6-S Shaking Table?

Install fixed bracket according to set longitudinal slope.

Place bed head and machine foot on bracket (slope adjustment handwheel should be set in feeding direction).

Ensure center point of second machine foot and three points on bedside linkage seat are aligned.

Correct position where four-bed support plate connectors of second machine feet engage with bed and fix bolts.

Pour appropriate amount of lubricating oil into connector.

Position support plates in four connectors towards concentrate.

Smoothly place bed surface on machine foot support plate, correct contact position between support plate and bed surface base.

Rotate pulley of transmission box by hand to retract reciprocating rod into box to endpoint; move front of bed so that four support plates of machine feet stand upright. Connect traction rod of bed surface with linkage seat of bed head in straight line, tighten bolts to secure.

7.How to Measure Bed Slope?

Accurately measure required height difference between two ends of transparent plastic tube filled with clean water and horizontal line. This will give you the desired slope.

8.How to Set The Bed Surface’s Horizontal (slope) Height Difference?

After setting predetermined height difference between left and right sides, use slope adjustment handwheel on machine foot for fine adjustment. Clockwise rotation raises the bed surface towards ore feeding direction; counterclockwise rotation raises it towards tailings side. For fine adjustment of longitudinal slope, adjust connection box on machine foot support plate: loosen channel steel bolts first, then turn screws on side of connection box to raise or lower body for adjusting longitudinal slope. Once slope is determined, tighten channel steel fixing bolts.

9.How to Debug Shaking Tables?

Before starting, lubricate all parts by injecting oil into bottom plate bearing seat.

When starting, ensure pulley runs clockwise; if reversed, adjust power wiring accordingly.

During installation and debugging process, avoid pressing spring too tightly in transmission case; slightly loosen it so there’s a slight impact sound during operation. Gradually tighten rear bolts until sound disappears without making spring too loose or tight.

Fine-tune slope and adjust ore-feeding concentration, volume, and flushing water according to mineral movement conditions on bed surface (appropriate flushing water volume is indicated by thin water layer on mineral surface).