Gold CIP/CIL Processing Plant

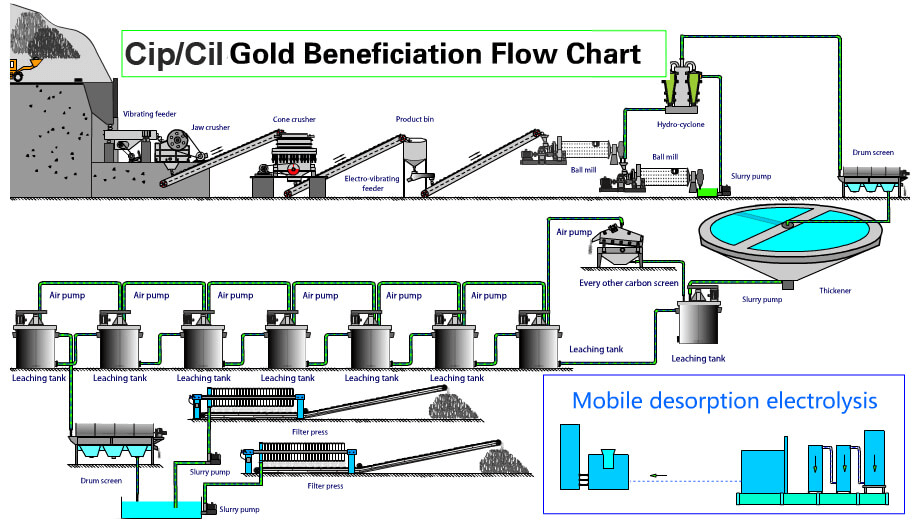

The gold CIP/CIL processing plant is a non-filtering cyanide pulp process that uses activated carbon to directly adsorb and recover gold from cyanide pulp, including seven stages: preparation of leaching pulp, cyanide leaching, activated carbon adsorption, desorption of gold loaded carbon, preparation of gold slime by electric shock, recycling of gold removal carbon and treatment of leaching pulp.

Cyanide Carbon Leaching Process Introduction

The cyanidation carbon leaching process is mainly a high recovery mineral processing flow for gold ore.

The earliest introduction to China was in the 1980s when it was first used in gold mines in Lingbao City, Henan Province, China. In the early days, sodium cyanide was mainly used for gold extraction in the cyanidation carbon pulp process, but with increasingly stringent environmental policies, sodium cyanide has gradually been replaced by environmentally friendly gold extraction agents.

The cyanidation carbon leaching process generally includes four parts: crushing, grinding, cyanidation, and activated carbon adsorption. The crushing and grinding are usually carried out in the same workshop, while cyanidation and activated carbon adsorption usually require a larger site and a better ventilation environment.

Cyanide Carbon Leaching Process flow

Pulp impurity removal

Before adsorption of cyanide pulp, wood chips and other impurities shall be treated to prevent gold and activated carbon in wood chips adsorption pulp from mixing into rich carbon, and prevent wood chips from blocking the carbon-separation screen.

Leaching and adsorption

Add activated carbon into the leaching tank. The activated carbon adsorbs the gold in the pulp to become gold loaded carbon. After adsorption, the activated carbon and pulp are separated by carbon extraction sieve.

Desorption electrolysis

Gold loaded carbon can be rapidly desorbed and electrolyzed into gold mud and lean carbon under the conditions of high temperature and high pressure in a closed system.

Smelt

After simple pickling and removal of impurities, the obtained gold mud can directly smelt gold ingots.

Main Machine :Vibrating feeder, Jaw crusher, Ball mill,Cone crusher, Hydrocyclone Mix tank,Carry carbon screen,Carbon-separation screen, Desorption electrolysis

For the cyanidation process, it is only when the grinding particle size reaches at least 70-80% 200 mesh that the cyanidation process may not be affected. In the cyanidation process, we also divide the cyanidation process into CIL and CIP based on the different adsorption sequences of activated carbon. CIL refers to the simultaneous leaching and adsorption of activated carbon, while CIP refers to the first leaching followed by adsorption. After doing many cyanidation projects, we found that CIL’s combination of leaching and adsorption is more conducive to actual production activities.

From a technical perspective, compared to gravity separation and flotation, the cyanidation carbon leaching process has the highest recovery rate for gold ore, with a recovery rate of no less than 90%.

From an economic perspective, compared to gravity separation and flotation, the cost of the cyanidation carbon leaching process is also the highest.

What is the difference between CIP and CIL?

CIP(Carbon in Pulp)

Main steps: impurity removal from ore pulp, leaching and adsorption, desorption electrolysis, and smelting.

Application: Flotation of gold concentrate or amalgamation, gravity separation of tailings, argillaceous oxide ore.

Advantages: convenient site selection.

CIL(Carbon In Leach)

Main steps: crushing, grinding, leaching, desorption electrolysis, tailings dehydration

Advantages: low investment, low cost, short infrastructure time, few production links, and small floor space.

How to Distinguish Between CIP and CIL?

CIP (Carbon In Pulp), that is, gold extraction by carbon pulp method. It is a non-filtering cyanide carbon slurry process that directly uses activated carbon to absorb and recover gold from cyanide pulp. It mainly includes seven operation stages: preparation of leaching pulp, cyanide leaching, activated carbon adsorption, gold-loaded carbon desorption, gold mud obtained by electric shock, recirculation of gold-removed carbon, and treatment of leaching pulp.

CIL (Carbon In Leach), that is, carbon leaching method for gold extraction. It is a process in which activated carbon is added to ore pulp while leaching and adsorption are carried out at the same time. Simplifies the leaching and cyanidation of the CIP process.

Gold Extraction Process as Follows

Raw material preparation-Cyanide leaching-Solid-Liquid separation-Extraction of gold from cyanide or cyanide pulp-Smelting to get gold ingot.

Summary

Currently, globally, the cyanidation carbon leaching process has gradually become the preferred process for most gold mine owners when processing gold, because it has better recovery rates and is more inclusive of the properties of different gold mines. However, considering the cost, many gold mine owners prefer to use small processing capacity for ore processing first, and then expand the processing capacity when good results can be obtained.