Copper mines refer to all available natural mineral aggregates containing copper. High-grade copper concentrate can be obtained by coarse grinding, roughing, scavenging of copper ore, followed by grinding and concentrating of the coarse concentrate.

Classification of copper ore

The beneficiation process needs to be customized due to the different types and nature of the ore. The specific process for selecting copper ore depends mainly on the material composition, structure, and occurrence state of copper in the original ore.

In general, copper ore can be categorized into three groups: copper sulfide ore, copper oxide ore, and natural copper.

| Types | Minerals |

| Copper sulfide ore | chalcopyrite, bornite and chalcocite, etc. |

| Copper oxide ore | cuprite, malachite, azurite, silicon malachite, etc. |

| Natural copper | little natural copper in nature |

Methods for copper ore beneficiation

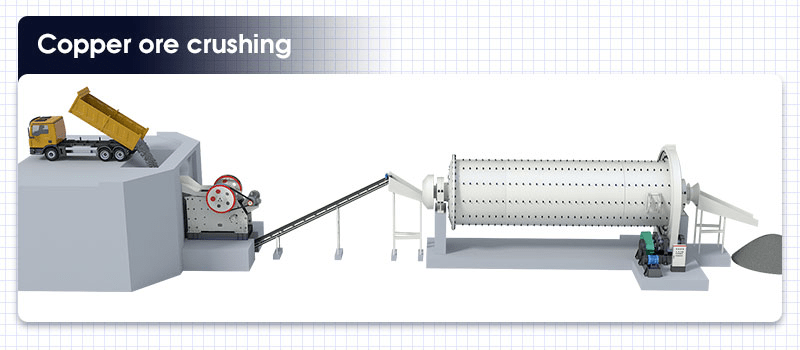

Crushing and grinding are necessary steps prior to the beneficiation of copper ores. The bulk ores undergo crushing, typically by a jaw crusher or cone crusher, reducing them to approximately 12cm in size. Subsequently, the crushed materials are transferred to grinding equipment where the final particle size of the copper ore is reduced to 0.15-0.2mm.

Copper ore crushing process

1. Copper sulfide ore beneficiation methods

Copper sulfide ores can be categorized as single copper ore, copper sulfur ore, copper-molybdenum deposit, copper nickel, carrollite, and others. Generally speaking, only flotation is applicable for their separation.

Virtually all copper sulphide ores contain iron-bearing sulfides. Therefore, the flotation of copper sulfide essentially involves separating it from iron sulfide. The typical iron sulfide minerals found in copper ore are pyrite and pyrrhotite.

Chalcopyrite: a kind of copper oxide ore

The main factors that affect the flotation of copper-bearing pyrite are:

- Disseminated grain size and symbiotic relationship between copper and iron sulfide. Generally, pyrite has a coarse grain size, while copper ore, especially secondary copper sulfide, is closely associated with pyrite. Only when the copper ore is finely ground can it be separated from pyrite. This characteristic can be utilized to select mixed concentrates of copper and sulfur, discard the tailings, and then grind and separate the mixed concentrate.

- The influence of secondary copper sulfide minerals. When the content of secondary copper sulfide minerals is high, the presence of copper ions in the slurry will increase. This will activate the pyrite and make Cu-S separation more difficult.

- The influence of pyrrhotite. A high content of pyrrhotite will affect the flotation process of copper sulfide minerals. Pyrrhotite oxidation consumes oxygen in the pulp, which can prevent initial flotation of copper minerals in severe cases. Increasing inflation can help improve this issue.

There are three common flotation processes:

Preferential flotation

Typically, copper is floated first, followed by sulfur. The dense massive copper-bearing pyrite contains a significant amount of pyrite and requires high alkalinity (free CaO content > 600-800g/m3) and a large dosage of xanthine to suppress it. The tailings mainly consist of pyrite with few gangues, resulting in sulfur concentrates.

Preferential flotation of copper sulfide ore beneficaition

For disseminated copper-sulfur ore, we use the preferential flotation process and re-float the sulfur in the tailings. To reduce sulfuric acid consumption during flotation and ensure safe operation, it is recommended to use low alkalinity conditions as much as possible.

Bulk flotation

It is more advantageous for copper sulfur ore with lower sulfur content and easily floatable copper. First, carry out bulk flotation in weakly alkaline pulp, then add lime to separate copper and sulfur in highly alkaline pulp.

Semi-preferential bulk separation flotation

In semi-preferential bulk separation flotation, collectors such as Z-200, OSN-43 or ester-105 with good selectivity are used to float copper minerals first. The resulting copper concentrate undergoes copper-sulfur bulk flotation, followed by separation flotation of floating copper and suppression of sulfur.

Semi-preferential bulk-separation flotation of copper sulfide ore beneficiation

It avoids the inhibition of easily floating copper under high lime consumption and does not require a large amount of sulfuric acid-activated pyrite. It has reasonable structure, stable operation, good index, and early recovery of target minerals.

The floatability of copper sulfide minerals:

Minerals without iron, such as chalcopyrite and covellite, have similar floatability with weak inhibitory effects from cyanide and lime.

Iron-bearing copper minerals like chalcopyrite and porphyry are easily inhibited by cyanide and lime in alkaline media.

The xanthate collector primarily chemisorbs with Cu (2+) cations. Minerals containing more Cu (2+) on their surface have a strong interaction with xanthate. The order of effectiveness is: chalcocite > covellite > porphyrite > chalcopyrite.

Factors such as crystal size, mosaic size, original or secondary nature also affect the floatability of copper sulfide minerals. Minerals with fine crystals and mosaic sizes are difficult to float. Secondary copper sulfide ore oxidizes easily and is more challenging to float compared to original copper ore.

For grinding and flotation processes, it is advantageous to adopt stage grinding and flotation for refractory copper ore. This includes re-grinding and re-separation of coarse concentrate, re-grinding and re-separation of bulk concentrate, as well as separate treatment for medium-grade ore.

2.Methods for Beneficiating Copper Oxide Ore

Copper oxide (CuO) is not soluble in water, ethanol, or acidic solutions but can dissolve slowly in ammonia solution and react with alkalis. The main beneficiation methods for oxidized copper ore are gravity separation, magnetic separation (for more information, refer to the details on copper ore processing plant), flotation, and chemical beneficiation.

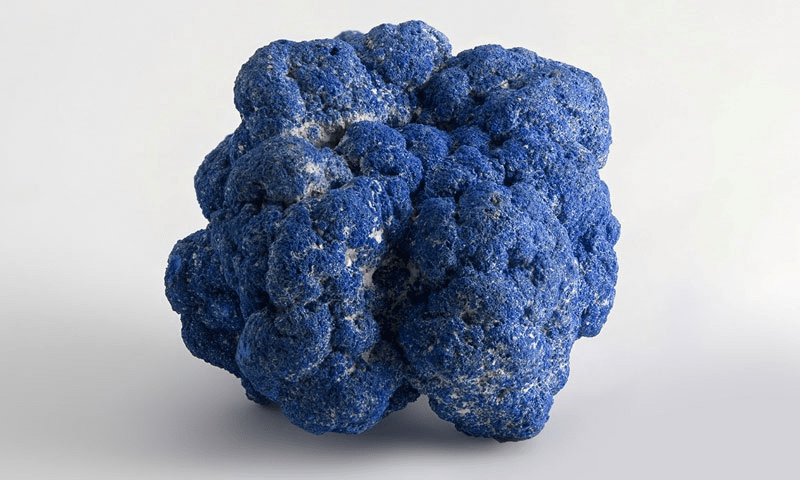

Azurite: a kind of copper oxide ore

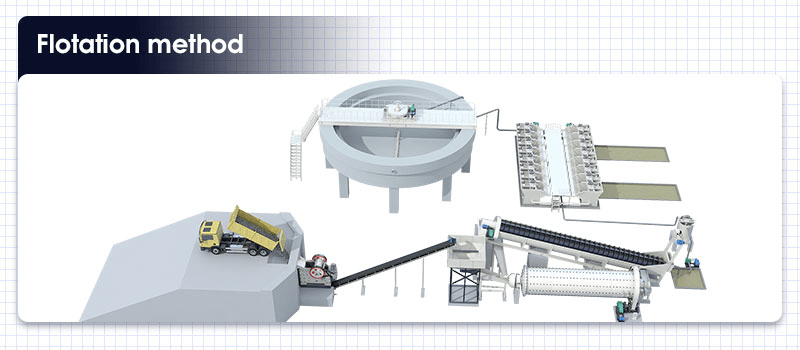

Flotation Method

Flotation is a commonly used technique in mineral processing for copper oxide ores. Depending on the properties of the copper oxide ores, various methods are employed, including sulphidizing flotation, fatty acid flotation, amine flotation, emulsion flotation, and chelating agent-neutral oil flotation.

Flotation method of copper oxide ore

- Sulphidizing flotation

The oxidized ore is vulcanized by adding a vulcanizing agent, and then flotation is carried out using the standard reagents for copper sulphide flotation.

Application scope: primarily malachite, azurite, and atacamite.

Process flow: The dosage of sodium sulfide can reach 1-2kg/t during vulcanization. Since the film produced by vulcanization is not stable and easily falls off after vigorous stirring, sodium sulfide should be added in batches as it is prone to oxidation.

Additionally, malachite and azurite have relatively fast vulcanization speeds. Therefore, the vulcanizing agent can be directly added to the first flotation cell without prior stirring. Adjusting the amount of vulcanizing agent according to foam state is necessary.

Reagent usage:

When there is excessive mud in the sludge: water glass must be added.

Collector: butyl xanthine or a mixture of butyl xanthine with aerofloat.

Flotation pulp pH value: approximately 9.

Improving flotation index: ammonium sulfate, sulfuric acid, etc.

- Flotation with Fatty Acids

Fatty acids and their soaps are primarily used as collectors in fatty acid flotation, also known as direct flotation. During the process, water glass (gangue inhibitor), phosphate, and sodium carbonate (slurry regulator) are typically added.

Application: Suitable for copper oxide minerals with non-carbonate gangue.

There is a practice of combining vulcanization and fatty acid methods. First, float the copper sulfide and a portion of the copper oxide using sodium sulfide and xanthate, then float the remaining copper oxide using fatty acid.

For example, at the Nchanga processing plant in Zambia, ore containing 4.7% copper achieved a copper content of 50% to 55% through flotation by adding 500g/t of lime (pH 9 to 9.5), 10g/t of cresol (foaming agent), 60g/t of ethylxanthate, 35g/t of amyl xanthate, 1kg/t of sodium sulfide, 40g/t of palmitic acid, and 75g/t of fuel oil.

- Amine Flotation

Amines are mainly used as collectors in this method. It can be applied not only for separating copper oxide but also for beneficiation processes involving lead and zinc minerals.

Application: Suitable for malachite, azurite, chlorchlorite ores etc.

The premise of amine flotation is to first find effective inhibitors for gangue minerals such as seaweed powder or polyacrylic acid.

- Emulsion Flotation

This method involves sulfurizing the copper oxide mineral first before adding an accessory ingredient to create a stable oil-wet surface on which neutral oil emulsion is applied to cover the mineral surface resulting in strong hydrophobic floating state. This allows firm attachment between minerals and foams facilitating separation.

Emulsion flotation includes three aspects:

- Use selective copper accessory ingredients such as benzotriazole, mercaptobenzothiazole, diphenyl guanidine, etc.

- Add non-polar oil emulsion to enhance mineral and foam adhesion.

- Utilize selective inhibitors like acrylic polymers and sodium silicate.

- Chelating Agent-Neutral Oil Flotation

This method utilizes a mixture of chelating agent and neutral oil as a collector for flotation.

Application: Suitable for refractory copper oxide minerals (e.g., silicon malachite).

It not only exhibits high selectivity and collecting efficiency but also ensures high sorting accuracy while reducing reagent consumption. Chelating agents also possess selective inhibition effects.

However, the cost of chelating agents is relatively high. Currently used chelating agents include polyamine and condensation of organic halides, among others.

In the flotation of copper ore, several issues need to be addressed:

Various factors should be considered in the flotation process of copper ore, including the duration of vulcanization, whether sodium sulfide should be added incrementally or all at once, and the proportion of chemicals used. Here is a brief overview.

Vulcanization time: Different ores require different vulcanization times. Generally, shorter durations are preferred. The optimal vulcanization time ranges from 1 to 3 minutes. Beyond 6 minutes, both recovery rate and concentrate grade decrease.

Incremental addition of sodium sulfide: In concentrator operations, the roughing stage typically lasts around ten minutes. However, when dealing with ore containing significant amounts of carbonaceous gangue that causes rapid disappearance of divalent sulfur ions in slurry, adding sodium sulfide incrementally yields better results than a single addition.

Proportional addition of sodium sulfide: Copper oxide tends to float at a slower pace in liquid form. Reducing the number of mineral cycles during flotation can lead to higher recovery rates. Therefore, studying the distribution ratio of sodium sulfide among different stages is crucial for capturing minerals at their optimal timing.

Chemical beneficiation:

The chemical beneficiation method is commonly employed for refractory copper oxide and mixed copper ores. When faced with high-copper-content oxide minerals characterized by fine mosaic size and abundant sludge formation, chemical beneficiation proves more effective than flotation due to separation difficulties.

This approach offers numerous advantages such as simple process flow, low investment requirements, minimal energy consumption and pollution levels along with low production costs.

Chemical beneficiation of copper oxide ore

Acid leaching, precipitation, flotation

Application: Malachite, cuprite, tenorite, copper mine tailings, etc., excluding copper ore with calcium magnesium carbonate gangue.

Firstly, the ore is ground and then leached with a dilute solution of sulfuric acid ranging from 0.5% to 3%. (For difficult-to-leach ores, heating to 45-70°C during leaching may be necessary).

The oxidation of copper minerals dissolves to produce copper sulfate which is subsequently replaced by iron filings to precipitate metallic copper.

Finally, float the metallic copper and insoluble copper sulfide minerals in sulfuric acid to obtain copper concentrate.

Ammonia leaching

Application: Oxidized copper ore containing calcium and magnesium carbonate gangue minerals.

A solution of ammonia and ammonium carbonate at a concentration of 12.5% was used as the solvent for leaching at a temperature of 150℃ and pressure between 1925175~2026500Pa for 2.5 hours. The mother liquor can be distilled using steam at 90℃ to separate ammonia and carbon dioxide. Copper is precipitated from the solution as black copper oxide powder.

Flotation – magnetic – metallurgy

Due to some loosely combined copper oxide minerals with iron or manganese, it is challenging to separate them solely through magnetic separation; however, flotation achieves good separation results.

Therefore, flotation is employed for obtaining high-grade concentrates while magnetic separation is used for tailings before proceeding with wet smelting. This process effectively combines flotation, magnetic separation, and wet smelting resulting in significantly increased recovery rates and reduced beneficiation costs.

These are several common beneficiation methods for treating copper oxide minerals. For selecting appropriate methods tailored specifically for each case involving such minerals it’s advisable to conduct professional beneficiation tests based on comprehensive reports.

Copper ore dressing equipment

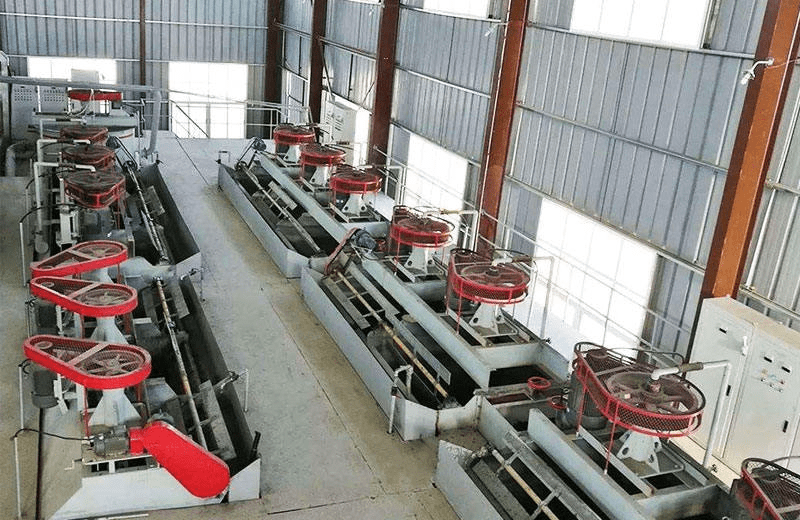

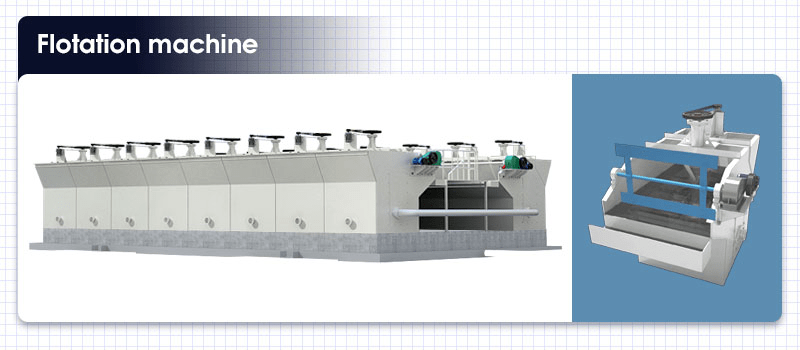

- Flotation machine

Flotation is the most commonly used method in copper mining. The copper ore pulp is stirred and aerated, causing the ore particles to stick to the foam created by various flotation agents. The foams rise and form a layer of mineralized foam, which is then scraped off or overflowed by a scraper. All these flotation processes are carried out in the flotation machine. (Contact Manufacturer)

Flotation machine for copper ore dressing

Advantages of Copper Ore Flotation Machine Performance

The copper flotation machine enhances the collision likelihood between coarse particles and foams, improving the mineralization effect of coarse particles. This reduces material mismatch and boosts concentrate recovery rate.

Moreover, the copper mine flotation machine exhibits excellent stability, eliminating the need for a special foundation during installation. This saves manpower, energy, and materials in the installation process.

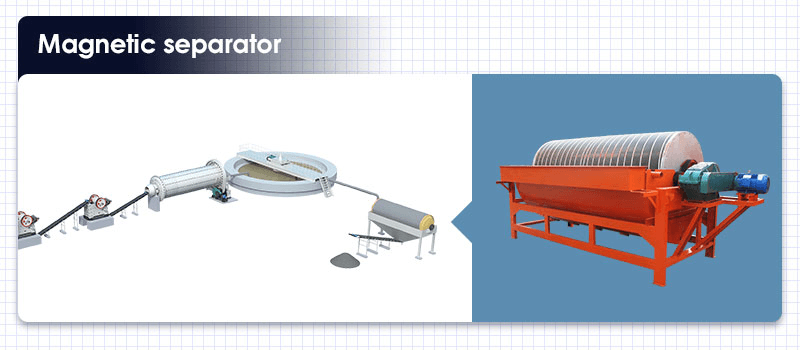

- Magnetic Separator

The magnetic separator is used to extract valuable magnetic minerals from copper ore, enhancing the quality of the ore and maximizing resource utilization while minimizing waste.

Magnetic separator for copper ore dressing

Performance advantages of magnetic separator:

(1) Advanced technology

The internal magnetic system of the drum utilizes a short circuit design to eliminate magnetic resistance at high speeds, preventing the stainless-steel drum from generating excessive heat and prolonging the lifespan of the magnetic block.

(2) Superior material selection

With its dynamic magnetic system design, the roller does not adhere to materials, facilitating efficient sorting. The selected grade can be increased by 3-6 times, reaching over 65%.

Author : Jordan Last Updated : Mar 13, 2023

All available copper-bearing natural mineral aggregates are called copper mines. The high-grade copper concentrate can be obtained by the coarse grinding, roughing, scavenging of copper ore, then grinding and concentrating of coarse concentrate.

Classification of copper ore

Due to the different types of ore, the nature of the ore is also different, so the beneficiation process needs to be customized. The specific process for selecting copper ore depends mainly on the material composition, structure and copper occurrence state of the original copper ore.

Generally speaking, copper ore can be divided into three categories: copper sulfide ore, copper oxide ore and natural copper.

Types Minerals

Copper sulfide ore chalcopyrite, bornite and chalcocite, etc.

Copper oxide ore cuprite, malachite, azurite, silicon malachite, etc.

Natural copper little natural copper in nature

Copper ore beneficiation methods

Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 0.15-0.2mm.

Copper ore crushing process

Copper ore crushing process

- Beneficiation methods of copper sulfide ore

Copper sulfide can be divided into single copper ore, copper sulfur ore, copper-molybdenum deposit, copper nickel, carrollite and so on. Basically, only flotation can be considered in its separation.

Almost all copper sulphide ores contain iron-bearing sulfides, so in a sense, the flotation of copper sulfide is essentially the separation of copper sulfide from iron sulfide. The common iron sulfide minerals in copper ore are pyrite and pyrrhotite.

Chalcopyrite a kind of copper oxide ore

Chalcopyrite: a kind of copper oxide ore

The main factors affecting the flotation of copper-bearing pyrite:

Disseminated grain size and symbiotic relationship of copper and iron sulfide. Generally, pyrite has a coarse grain size, while copper ore, especially secondary copper sulfide, is closely associated with pyrite. Only when the copper ore is finely ground can it be dissociated from pyrite. This characteristic can be used to select copper-sulphur mixed concentrates, discard the tailings, and then grind and separate the mixed concentrate.

The influence of secondary copper sulfide minerals. When the secondary copper sulfide mineral content is high, the copper ions in the slurry will increase, which will activate the pyrite and increase the difficulty of Cu-S separation.

The influence of pyrrhotite. The high content of pyrrhotite will affect the flotation of copper sulfide. Pyrrhotite oxidation will consume the consumption of oxygen in the pulp. In severe cases, the copper minerals do not float at the beginning of flotation. This can be improved by increasing inflation.

There are three common flotation processes:

Preferential flotation

Generally, copper is floated firstly and then sulfur. The content of pyrite in dense massive copper-bearing pyrite is quite high and high alkalinity (free CaO content> 600~800g/m3) and high dosage of xanthine are often used to suppress the pyrite. There is mainly pyrite in its tailings with few gangues, so the tailings are sulfur concentrates.

Preferential flotation of copper sulfide ore beneficaition

Preferential flotation of copper sulfide ore beneficaition

For the disseminated copper-sulfur ore, the preferential flotation process is adopted, and the sulphur in the tailings must be re-floated. To reduce the consumption of sulfuric acid during the floatation and ensure safe operation, the process condition of low alkalinity should be adopted as far as possible.

Bulk-separating flotation

It is more advantageous for copper sulfur ore containing less sulfur with copper easy to be floated. Carry out the bulk flotation firstly in the weakly alkaline pulp and then add lime to the mixed concentrate to separate the copper and sulfur in the highly alkaline pulp.

Semi-preferential bulk-separation flotation

In semi-preferential bulk-separation flotation, Z-200, OSN-43 or ester-105 with good selectivity are used as collectors to float copper minerals firstly. The copper concentrate is then subjected to copper-sulfur bulk flotation and the obtained copper-sulfur mixed concentrate is subjected to separation flotation of floating copper and suppressing sulfur.

Semi-preferential bulk-separation flotation of copper sulfide ore beneficiation

Semi-preferential bulk-separation flotation of copper sulfide ore beneficiation

It avoids the inhibition of the easily floating copper under high lime consumption and does not require a large amount of sulfuric acid-activated pyrite. It has the characteristics of reasonable structure, stable operation, a good index and early recovery of target minerals.

The floatability of copper sulfide minerals :

All minerals that do not contain iron, such as chalcopyrite and covellite, have similar floatability and the inhibitory effect of cyanide and lime on them is weak.

All iron-bearing copper minerals, such as chalcopyrite and porphyry, are easily inhibited by cyanide and lime in alkaline media.

The xanthate collector mainly plays the role of chemisorption together with the cation Cu (2 +), so minerals whose surface contains more Cu (2 +) minerals have a strong effect with the xanthate. The order of the effect is: chalcocite > covellite > porphyrite> chalcopyrite.

The floatability of copper sulfide minerals is also affected by factors such as crystal size, mosaic size, being original or secondary. The minerals with fine crystal and mosaic size are difficult to float. Secondary copper sulfide ore is easy to oxidize and more difficult to float than original copper ore.

As for the grinding and floating process, it is more advantageous to adopt the stage grinding and floating process for refractory copper ore, such as the re-grinding and re-separation of coarse concentrate, re-grinding and re-separation of bulk concentrate, and separate treatment of medium ore.

- Beneficiation methods of copper oxide ore

Copper oxide (CuO) is insoluble in water, ethanol, soluble acid, ammonium chloride and potassium cyanide solutions. It can react with alkali when slowly dissolving in ammonia solution. The beneficiation methods of oxidized copper ore mainly include gravity separatio, magnetic separation (see details on copper ore processing plant), flotation and chemical beneficiation.

Azurite a kind of copper oxide ore

Azurite: a kind of copper oxide ore

Flotation method

Flotation is one of the commonly used mineral processing techniques for copper oxide ores. According to the different properties of copper oxide ores, there are sulphidizing flotation, fatty acid flotation, amine flotation, emulsion flotation and chelating agent-neutral oil flotation method.

Flotation method of copper oxide ore

Flotation method of copper oxide ore

- Sulphidizing flotation

The oxidized ore is vulcanized by adding vulcanizing agent and then the flotation is carried out with the ordinary reagents of copper sulphide flotation.

Scope of application: mainly malachite, azurite and atacamite.

Process flow: The dosage of sodium sulfide can reach 1~2kg/t during vulcanization. Because the film produced by vulcanization is not stable and is easy to fall off after vigorous stirring, and sodium sulfide itself is easily oxidized, sodium sulfide should be added in batches.

Besides, the vulcanization speed of malachite and azurite is relatively fast, so the vulcanizing agent can be directly added to the first flotation cell with no need to stir in advance during vulcanization and adjust the amount of vulcanizing agent according to the foam state.

Use of reagents:

When there is much mud in the sludge: water glass must be added.

Collector: butyl xanthine, or butyl xanthine mixed with aerofloat.

The PH value of flotation pulp: around 9.

Improve the flotation index: ammonium sulfate, sulfuric acid, etc.

- Fatty acid flotation

Fatty acids and their soaps are mainly used as collectors of fatty acid floatation, also known as direct flotation. During flotation, water glass (gangue inhibitor), phosphate, and sodium carbonate (slurry regulator) are also usually added.

Scope of application: copper oxide mineral whose gangue is not carbonate.

There is a practice of mixing vulcanization and fatty acid methods. Firstly float the copper sulfide and part of the copper oxide with sodium sulfide and xanthate, and then float the residual copper oxide with fatty acid.

For example, the ore in the Nchanga processing plant in Zambia contains 4.7% copper. The copper content achieved to 50% ~ 55% through flotation by adding 500g/t of lime (pH 9 ~ 9.5), 10g/t of cresol (foaming agent), 60g/t of ethylxanthate, 35g/t of amyl xanthate, 1kg/t of sodium sulfide, 40g/t of palmitic acid and 75g/t of fuel oil.

- Amine flotation

Amines are mainly used as collectors in this method. It can be used not only for the separation of copper oxide, but also for the beneficiation of copper oxide, lead, and zinc minerals.

Scope of application: malachite, azurite and chlorchlorite, etc.

The premise of amine flotation method is to firstly find effective inhibitors of gangue, such as seaweed powder, polyacrylic acid, etc.

- Emulsion flotation

It is mainly to sulfurize the copper oxide mineral firstly and then add the copper accessory ingredient to create a stable oil-wet surface. Then, the neutral oil emulsion is used to cover the mineral surface, resulting in a strong hydrophobic floating state. In this way, the mineral can be attached to the foams firmly to complete the separation.

Emulsion flotation includes three aspects:

1Use the selective copper accessory ingredients, including benzotriazole, mercaptobenzothiazole, diphenyl guanidine, etc.

2Add non-polar oil emulsion to improve the adhesion of minerals and foams.

3Use selective inhibitors such as acrylic polymers and sodium silicate.

- Chelating agent-neutral oil flotation

It completes the flotation by using the mixture of the chelating agent and neutral oil as a collector.

Scope of application: refractory copper oxide (such as silicon malachite)

It not only has high selectivity and collecting effect, but also can guarantee high sorting index and reduce the consumption of reagents. Chelating agents also have selective inhibition effect.

However, the cost of chelating agents is relatively high. Currently, the chelating agents used include polyamine and condensation of organic halides, etc.

Problems should be noticed in the flotation of copper ore:

Many problems should be paid attention to in the flotation of copper ore, such as the length of the vulcanization time, whether to add sodium sulphide in batches and the proportion of chemicals. Here is a brief introduction.

The vulcanization time. Different ores require different vulcanization times. Generally speaking, it should be short rather than longer. The suitable vulcanization time is 1 to 3 minutes. After 6 minutes, the recovery rate and concentrate grade will decrease.

Add sodium sulfide in batches. The roughing time for processing the ore in the concentrator is about ten minutes, while the ore contains a large amount of carbonaceous gangue and the divalent sulfur ions disappear quickly in the slurry. So the effect of adding sodium sulfide in batches is better than that of adding it once.

Add sodium sulfide proportionally. Generally, copper oxide floats in the liquid at a slower speed, and reduce the number of cycles of the mineral in the flotation process can obtain a higher recovery rate. It is of great significance to study the distribution ratio of sodium sulfide among different operations to catch the mineral at the right time.

Chemical beneficiation

The chemical beneficiation method is often used for refractory copper oxide and mixed copper. For some copper oxide minerals with high copper content, fine mosaic size and rich sludge, the chemical beneficiation method will be used to obtain good indicators because the flotation method is difficult to realize the separation.

It has many advantages such as simple process flow, low investment, low energy consumption, light pollution and low production cost.

Chemical beneficiation of copper oxide ore

Chemical beneficiation of copper oxide ore

Acid leaching—precipitation—flotation

Scope of application: malachite, cuprite, tenorite, copper mine tailings, etc., except copper ore containing calcium magnesium carbonate gangue.

The ore is first leached with a 0.5% to 3% sulfuric acid dilute solution after being ground. (For some ore that is difficult to be leached, it needs to be heated to 45 to 70° C during leaching).

The oxidation of copper mineral dissolves to generate copper sulphate that will be replaced with iron filings to restore copper ions to metallic copper for precipitation.

Finally, float the metallic copper and copper sulfide minerals insoluble in sulfuric acid to obtain copper concentrate.

Ammonia leaching

Scope of application: oxidized copper ore containing calcium and magnesium carbonate gangue minerals

The solution of ammonia and ammonium carbonate in a concentration of 12.5% was used as the solvent to leach for 2.5h at a temperature of 150℃, a pressure of 1925175~2026500Pa. The mother liquor can be distilled by steam at 90℃ to separate ammonia and carbon dioxide. Copper, on the other hand, is precipitated from the solution as black copper oxide powder.

Floatation – magnetic – metallurgy

Because some copper oxide minerals are not tightly combined with iron, manganese, etc., it is difficult to separate them by using the magnetic separation method alone, and flotation has a good separation effect.

Therefore, the flotation method is used to obtain high-grade concentrates, the magnetic separation is for tailings and wet smelting is carried out finally. This process combines flotation, magnetic and wet smelting very well, which greatly increases the recovery rate and reduces the beneficiation cost.

The above are several common beneficiation methods for copper oxide minerals. For the selection of copper oxide minerals, it is best to conduct a professional beneficiation test and customize the process according to the report.

Copper ore dressing equipment

- Flotation machine

Flotation is the most widely used method in copper mine production. The copper ore pulp is stirred and aerated, and the ore particles adhere to the foams under the action of various flotation agents. The foams rise to form a mineralized foam layer, which is scraped or overflowed by the scraper. This series of flotation processes are all completed in the flotation machine. (Contact Manufacturer)

Flotation machine for copper ore dressing

Flotation machine for copper ore dressing

Performance advantages of copper ore flotation machine

The copper flotation machine increases the collision probability of coarse particles and foams, improves the mineralization effect of coarse particles, reduces the mismatch of materials and improves the recovery rate of concentrate.

The copper mine flotation machine itself has good stability, so no special foundation is required for installation, saving manpower, energy and materials during installation.

- Magnetic separator

Magnetic separator can recover useful magnetic minerals contained in copper ore. It can improve the taste of ore and the utilization rate of resources, and reduce the waste of resources.

Magnetic separator for copper ore dressing

Magnetic separator for copper ore dressing

Performance advantages of magnetic separator:

(1) High technology

The internal magnetic system of the barrel adopts a short circuit design to ensure that the barrel skin has no magnetic resistance at high speeds, and the stainless-steel barrel skin does not generate high temperatures, extending the life of the magnetic block.

(2) High taste in the selection

Since it adopts a dynamic magnetic system design, the roller does not stick to the material, which is conducive to material sorting. The selected grade can be increased by 3-6 times to more than 65%.

- Jigger

Copper mines are generally purified by flotation, but for the beneficiation of copper minerals with coarser grain size and higher density, the pre-selection by the gravity separation method will greatly reduce the cost and achieve flotation indicators.

Jigger for copper ore dressing

Jigger for copper ore dressing

Performance advantage of jigger

The jigger can be used to select both fine and coarse materials with the upper limit of its feeding grain size of 6-12 mm.

Large processing capacity and wide selection range.

- Shaking table

The shaking table is suitable for beneficiation of copper ore and can be used in different operation modes such as coarse separation, concentration and scavenging.

Shaking table for copper ore beneficiation

Performance advantages of shaking table

Compared with the traditional process, the shaker has the advantages of no use of reagents, low energy consumption and easy management.

Low investment cost.

Copper ore beneficiation plant

Below is a typical copper ore beneficiation plant in South Africa. It mainly uses the copper-lead bulk flotation separation method, which helps obtain copper and lead concrentrate.