What is Fluorite?

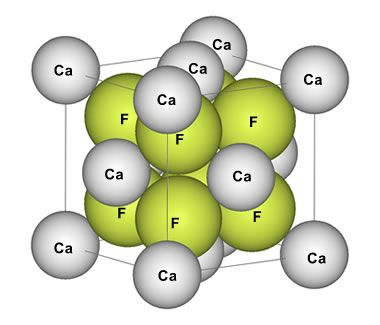

Fluorite, composed of calcium and fluorine (CaF2), is a significant industrial mineral. It finds application in various chemical, metallurgical, and ceramic processes. Exceptionally transparent and colorful specimens are either cut into gemstones or used for ornamental purposes.

ADVERTISEMENT

Fluorite forms through hydrothermal processes in vein deposits. In these rocks, it frequently occurs as a gangue mineral alongside metallic ores. Additionally, it can be found within fractures and cavities of certain limestones and dolomites. As a widely distributed rock-forming mineral, fluorite is commonly encountered across different regions worldwide. Within the mining industry, it is often referred to as “fluorspar.”

Physical Properties of Fluorite

Fluorite can be easily identified by considering its cleavage, hardness, and specific gravity. It is the only common mineral that exhibits perfect cleavage in four directions, often resulting in octahedral-shaped fragments. Additionally, it ranks a four on the Mohs Hardness Scale. Lastly, fluorite has a specific gravity of 3.2, which is noticeably higher than that of most other minerals.

While color alone may not provide reliable information for identifying minerals, the distinct purple, green, and yellow translucent-to-transparent appearance of fluorite serves as an immediate visual indicator for this mineral.

Fluorescence

In 1852, George Gabriel Stokes discovered that specimens of fluorite can emit a blue glow when exposed to light, which he described as “beyond the violet end of the spectrum.” He named this phenomenon “fluorescence” after the mineral fluorite. The term became widely accepted in various fields such as mineralogy, gemology, biology, optics, commercial lighting, and others. (Refer to the photo pair for an example of fluorescence in tumbled stones.)

Fluorite typically emits a blue-violet color under short-wave ultraviolet and long-wave ultraviolet light. Some specimens may emit a cream or white color instead. Not all specimens exhibit fluorescence. It is believed that fluorescence in fluorite occurs due to small amounts of yttrium, europium, samarium or other elements substituting calcium within its mineral structure.

| Physical Properties of Fluorite | |

| Chemical Classification | Halide |

| Color | Typically purple, green, and yellow. Also colorless, blue, red, and black. |

| Streak | White |

| Luster | Vitreous |

| Diaphaneity | Transparent to translucent |

| Cleavage | Four directions of perfect cleavage |

| Mohs Hardness | 4 |

| Specific Gravity | 3.2 |

| Diagnostic Properties | Cleavage, hardness, specific gravity, color |

| Chemical Composition | CaF2 |

| Crystal System | Isometric |

| Uses | Numerous uses in the metallurgical, ceramics, and chemical industries. A source of fluorine, hydrofluoric acid, metallurgical flux. High-clarity pieces are used to make lenses for microscopes, telescopes, and cameras. |

luorite Occurrence

Most fluorite occurs as vein fillings in rocks that have been subjected to hydrothermal activity. These veins often contain metallic ores which can include sulfides of tin, silver, lead, zinc, copper, and other metals.

Fluorite is also found in the fractures and vugs of some limestones and dolomites. Fluorite can be massive, granular, or euhedral as octahedral or cubic crystals. Fluorite is a common mineral in hydrothermal and carbonate rocks worldwide

Uses of Fluorite

Fluorite has a wide variety of uses. The primary uses are in the metallurgical, ceramics, and chemical industries; however, optical, lapidary, and other uses are also important.

Fluorspar, the name used for fluorite when it is sold as a bulk material or in processed form, is sold in three different grades (acid, ceramic, and metallurgical).

Acid Grade Fluorspar

Acid grade fluorspar is a high-purity material used by the chemical industry. It contains over 97% CaF2. Most of the fluorspar consumed in the United States is acid grade even if it is used in lower grade applications. It is used mainly in the chemical industry to manufacture hydrofluoric acid (HF). The HF is then used to manufacture a variety of products which include: fluorocarbon chemicals, foam blowing agents, refrigerants, and a variety of fluoride chemicals.

Ceramic Grade Fluorspar

Ceramic grade fluorspar typically contains 85% to 96% CaF2. This material is widely utilized in the manufacturing of specialty glass, ceramics, and enamelware. It is employed for creating glazes and surface treatments that result in hard glossy surfaces, opalescent appearances, and various other attractive or durable features on consumer glass objects. The non-stick cooking surface known as Teflon is produced using fluorine derived from fluorite.

Metallurgical Grade Fluorspar

Metallurgical grade fluorspar generally contains 60% to 85% CaF2. This material finds extensive use in the production of iron, steel, and other metals. It acts as a flux that eliminates impurities like sulfur and phosphorous from molten metal while enhancing slag fluidity. Approximately 20 to 60 pounds of fluorspar are used per ton of metal produced. In the United States, many metal producers employ fluorspar exceeding metallurgical grade standards.

Optical Grade Fluorite

Fluorite specimens with excellent optical clarity are utilized as lenses. With its low refractive index and dispersion, fluorite lenses produce incredibly sharp images. Nowadays, instead of using natural fluorite crystals, high-purity fluorite is melted and combined with other materials to create synthetic “fluorite” lenses of even higher quality. These lenses are employed in optical equipment like microscopes, telescopes, and cameras.

Lapidary Grade Fluorite

Fluorite specimens with remarkable color and clarity are commonly used by lapidaries for cutting gemstones and crafting ornamental objects. High-quality fluorites make stunning faceted stones; however, due to their softness and susceptibility to cleaving, these stones are either sold as collector’s items or used in jewelry that won’t be exposed to impact or abrasion. Fluorite is also carved into decorative objects such as figurines and vases. These pieces often undergo treatment with a coating or impregnation to enhance stability and protect against scratches.

Fluorite Production in the United States

Deposits of minable fluorite exist in the United States; however, nearly all of the fluorite consumed in the United States is imported. The primary countries that supplied fluorite to the United States in 2011 were China, Mexico, Mongolia, and South Africa. All of this fluorite is imported because production costs in the United States are so high that the material can be produced in these other countries and shipped directly to customers in the United States at a lower cost.

In 2011 several companies were producing and selling synthetic fluorite as a byproduct of their phosphoric acid production, petroleum processing, or uranium processing activities. A limestone producer in Illinois was also recovering and selling small amounts of fluorite from their quarry. That company is developing an underground mine to exploit a large vein of fluorite which they hope will be in production in 2013.