Gold-sulfur separation is a common process used in the extraction and refining of gold deposits. It involves separating gold and sulfur from ores that contain both elements. Below are some standard methods for gold-sulfur separation.

Gold-Sulfur Separation Method

Thermal treatment is typically the initial step in separating gold from sulfur. This involves subjecting the ore to high temperatures, causing sulfides to break down into sulfur gas (hydrogen disulfide or hydrogen sulfide gas) and metals.

Oxidation can convert sulfides in certain gold ores into oxides or sulfates, effectively separating sulfur from gold. This can be achieved using oxidizing agents like oxygen or chemicals.

Flotation is a physical method used to separate gold from mixtures containing gold ore. During flotation, the finely crushed ore is mixed with water and a special chemical that causes gold particles to attach to bubbles and rise to the surface while impurities such as sulfur sink.

Dissolution and Extraction involve dissolving the ore in an acidic or alkaline solution to isolate sulfur while selectively extracting gold using solvent extraction.

An atmosphere furnace is often employed during the process of separating gold from sulfur. It heats the ore and controls the atmosphere for effective decomposition of sulfur and extraction of gold.

Please note that specific methods for gold-sulfur separation may vary depending on factors such as ore type, concentration of gold, and physical properties of the ore. Different ores and process conditions may require different separation techniques. Additionally, strict environmental protection measures are usually necessary during this process to minimize negative impacts on the environment. Therefore, it is important to adhere to relevant regulations and standards when mining and processing gold.

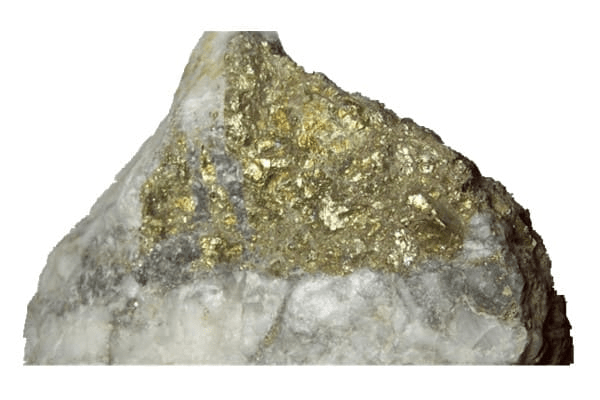

Pyrite

Pyrite is a common mineral in my country that contains significant reserves of gold. In non-ferrous metal beneficiation processes, pyrite concentrate is commonly referred to as sulfur concentrate. Gold within pyrite exists mainly in microscopic, submicroscopic, and lattice forms, making it challenging to extract from these ores. As China’s easily processed metallurgical reserves continue declining, efficient extraction of refractory (difficult-to-process)gold ores has become a major issue facing the gold industry today.

Pyrite Processing Plant

Ore information: The mineral ores contain 35.68% sulfur, 29.24% iron, and 3.65g/t gold, with high extraction value.

Based on phase analysis, the gold in the ore mainly exists as gold sulfide, gold oxide, and gold silicate. We need to disrupt the pyrite crystal structure in the sample to fully expose the gold mineral before we can recover it.

Pretreatment Process

The pretreatment process for pyrite involves oxidative roasting-acid dissolution, wet acidic oxidative decomposition, and wet alkaline oxidative decomposition. After pretreating the sulfur concentrate, a cyanide agent is used to extract gold from the resulting gold concentrate.

Optimal Conditions for Oxidation Roasting-Acid Dissolution

The optimal conditions for oxidation roasting-acid dissolution are:

Roasting temperature: 700°C; roasting time: 3 hours.

Acid dissolution at room temperature; liquid-to-solid ratio of 2ml/g; stirring; sulfuric acid dosage equivalent to 20% of the mass of roasted residue; acid dissolution time of 8 hours.

Under these optimal conditions, the average yield of gold concentrate is 52.4%, with all gold concentrated into it and a gold grade reaching up to 6.79g/t. We used this gold concentrate as a sample for leaching tests using a cyanide leaching agent. The optimal leaching conditions were: normal temperature; leaching agent dosage of 0.04%; leaching time of12h; liquid-to-solid ratio of3ml/g;pH valueof11 ;stirring speedof400r/min.Undertheseoptimalleachingconditions,theaverageleachingrateofAuinthegoldconcentrateafteroxidationroastingandaciddissolutiontreatmentwas89 .6%.

Optimal Conditions for Wet Acid Oxidation Decomposition

The optimal conditions for the wet acid oxidation decomposition test are:

Sample grinding fineness of 95%-200 mesh; Fe3+ dosage at 50% of theoretical dosage; hydrogen peroxide dosage at 120% of theoretical dosage; sulfuric acid dosage at 100% of theoretical dosage. Reaction temperature: 95°C; reaction time:8hours ;liquid-to-solid ratio :6ml/g ;stirring speed :400r/min . Under these optimal conditions, gold concentrate with a gold grade above9g/t was obtained. Under optimal leaching conditions, the average Au leaching rate was87.4%.

Optimal Conditions for Wet Alkaline Oxidation Decomposition

The optimal conditions for the wet alkaline oxidation decomposition test are:

Stirring and aeration reaction at room temperature for7days ;sample grinding finenessof95%-200mesh ;NaOHdosageat100%oftheoreticaldosage ;liquid-to-solidratioof3ml/g.Undertheseoptimalconditions,theaverage recoveryrateforgoldconcentratewas96.35%,andtheaveragegoldgradewas6.71g/t.Underoptimalleachingconditions,theAuleachingratewas82.2%.