Gold mining process

Gold serves as a unique currency for reserves and investments, while also playing a crucial role in various industries such as jewelry, electronics, modern communications, aerospace, and more. The value of gold acts as an incentive for individuals to engage in prospecting, mining, and processing of gold ore with the aim of extracting greater quantities. Consequently, the requirement arises for specialized equipment specifically designed for mineral processing within the realm of gold mining.

GUOGAO company is dedicated to offering gold miners efficient and durable equipment for gold mining, covering the entire process from crushing and grinding to gravity separation and flotation, enabling them to achieve a high rate of gold recovery.

Whether you are extracting alluvial gold, placer gold, quartz-based gold ore, or separating gold from lithium, silver, iron, copper, cobalt, or lead; you require equipment for gold beneficiation (commonly referred to as gold recovery equipment). Gravity-based gold recovery equipment, along with flotation equipment and magnetic separators specifically designed for processing gold are commonly used.

Gravity Gold Recovery Equipment

Shaking Table

The shaking table, also known as a gold recovery table or gold separation table, is the most effective equipment for recovering fine gold.

It can process various types of gold, including gold ore in quartz rock, gold stones, and placer gold.

The shaking table has a feeding particle size range of 3mm-0.019mm on average.

Gold beneficiation using this equipment is stable and reliable, with clearly visible distribution of the ore belt.

It requires no chemicals and consumes less electricity, resulting in lower operation costs.

Additionally, it can be utilized for dredging operations in Gold Wash Plants and Gravity Separation Plants.

Centrifugal concentrator

The Gold Centrifugal Concentrator is a highly efficient gravity separation equipment widely used in the mining industry, particularly for placer gold, fine-grain rock gold, and other precious minerals.

【Modes】

(1) Timed automatic discharge centrifuge: customizable with higher efficiency but at a higher price.

(2) Non-automatic discharge centrifuge: commonly used and readily available. It requires manual intervention to stop operation and remove the gold concentrate after a few hours of use. We offer both industrial and laboratory types of small centrifuges.

(3) Customized fixed or mobile concentrators (mobile gold wash plant typically equipped with portable trommel screen, portable gold centrifuge, portable gold shaker table, etc.)

【Brand】 Knelson Concentrator; GUOGAO gold concentrator is an excellent alternative to Knelson Concentrator due to its affordable price, complete models, and wide capacity range.

【Related Product】

Feeding: slurry pump or gravity flow based on height difference.

After using the gold centrifuge: tailings go into sluice box; concentrate goes into shaker table or amalgamator.

【Gold Concentrator VS Jig Concentrator】 The centrifugal gold concentrator is easier to adjust and provides safer handling of the extracted gold. However, it can only remove the concentrated gold after continuous operation for 4-6 hours.

Jig Concentrator

The Jig Concentrator is an effective machine that uses gravity separation based on the density difference of ore materials. It is mainly used for processing placer gold, coltan, tungsten, tin, and other minerals. The higher the density difference, the better the jigging separation effect.

There are different types of jig concentrators available: eccentric jig concentrator (plunger jig and diaphragm jig), hydraulic jigger, movable sieve jig, air pulsating jig, and trapezoid jig. The diaphragm jig has high beneficiation efficiency and can process coarse particle ores such as tungsten and tin with a particle size ranging from 0.5 mm to 16 mm.

The trapezoidal jig has a large processing capacity and can handle particles ranging from 50 mm to 0.25 mm. It has been widely used in tungsten, tin, and iron ore dressing plants. Depending on the beneficiation medium used, mineral jigs are divided into hydraulic jigs and dry jigs; dry material feeding yields better results.

The GUOGAO sawtooth jig machine uses water as the medium for fine gold recovery with low water consumption and continuous operation.

Before using the sawtooth jig machine: feed by belt conveyor or slurry pump automatically based on height difference or gravity flow. After using the sawtooth gig machine: separate gold concentrate onto a gold shaker table while sending tailings to a sluice box.

GUOGAO is a manufacturer of various types of mineral processing equipment including fixed jigs and mobile jigs machines customized according to your requirements. JXSC has been focusing on gravity separation techniques in mineral processing for decades offering more gravity separator machines such as spiral chutes,jigger machines (mineraljig concentrators),shaker tables,and centrifugal concentrators.

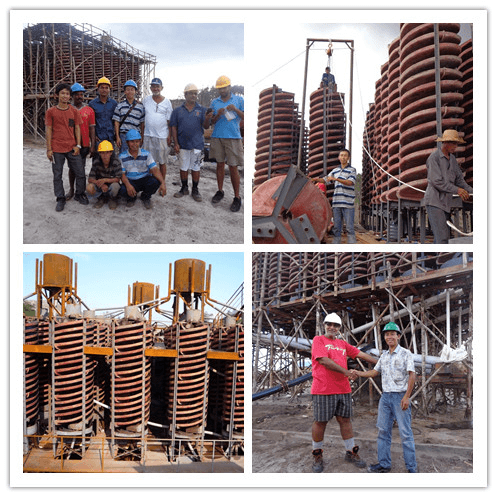

Spiral Chutes

It separates gold by utilizing the difference in specific gravity between gold and other minerals, especially when processing placer gold. Additionally, it is employed for separating iron, tin, wolframite, tantalum, niobium, chromite, rutile, monazite, and more. The material size ranges from 0.6 to 0.03mm. Compared to the gold shaker table, it is lighter and takes up less space which reduces transportation costs.

- It utilizes the specific gravity difference between gold and other minerals to separate gold. It works better when processing placer gold.

- It is also used to separate the iron, tin, wolframite, tantalum, niobium, chromite, rutile, monazite, etc.

- The material size ranges from 0.6-0.03mm.

- Compared with the gold shaker table, it is lighter and occupies a smaller area, reducing the transportation costs.

Gold Flotation Equipment

Gravity separation is not effective for recovering gold ores that are finer than 10 μm. Froth flotation, on the other hand, uses the hydrophobic properties of gold to separate it from gangue minerals and successfully recover fine-grained and ultra-fine-grained gold particles.

Flotation is suitable for processing sulfide-containing gold ore with high floatability, as well as polymetallic gold-bearing ores like gold-copper ore and gold-silver ore.

It is not advisable to use flotation for processing ores larger than 0.2mm in particle size or quartz-gold ores without sulfides.

Gold Magnetic Separator

Gold Ore Milling Machine

Grinding releases more gold from various sources such as quartz and granite gold ore, gold stones, hard rocks containing gold, tailings, and black sand. Insufficient grinding leads to a decrease in the recovery of gold. On the other hand, excessive grinding increases energy consumption, usage of grinding media and reagents, resulting in higher unit costs. Ball mills and wet pan mills are commonly employed for processing gold.

Ball Mill

There are two methods of ball milling: dry grinding and wet grinding. Gold ore grinding plants commonly use wet grinding.

In most cases, the inner surface of the shell is lined with wear-resistant materials to prolong its service life.

To enhance grinding efficiency, a classifier can be added to create a closed circuit and properly adjust the ratio of steel balls.

Wet Pan Mill

The wet pan mill, also known as a gold grinder mill, is a versatile grinding machine used for processing gold, silver, copper, and other ores.

Wet pan mills are an affordable alternative to ball mills and are highly efficient equipment for ore beneficiation in small and medium-sized gold processing plants.

Mercury is commonly added to the wet pan mill to combine with the gold particles, which is why it is often called an amalgamation grinding mill.

Gold sluice box

【Description】A gold sluice box with a mat is a type of equipment used for mineral gravity separation. It is primarily utilized in alluvial gold wash plants, gold dredgers, and open-pit gold mining operations. This equipment plays a crucial role in the process of panning for gold due to its high recovery rate, mature technology, wide application, and economic as well as environmental benefits.

【Types of sluice boxes】There are three types of sluice boxes: stationary sluice boxes, portable sluice boxes, and vibrating gold sluices. They can be further categorized based on their capacity into large-scale sluice boxes used in open-pit mining plants with an ore granularity range of 50-100mm; and small-sized mini gold sluice boxes found on gold dredgers and mobile gold mining plants where the granularity is less than 20mm.

【Related equipment】Preceding the use of a sluice box is the utilization of a gold centrifugal concentrator; following it is the employment of a gold shaker table.

【Sluice mat materials】The materials used for the construction of sluice mats include PE (polyethylene), rubber (both natural rubber and recycled material), plastic, etc.

【Small-sized sluice box】This portable device can be assembled within 30 minutes. It employs gasoline engines to pump placer sand from streams and rivers during shallow water area placer gold washing processes.

【Services offered】(1) Customization options available for both length and width dimensions of the sluice box.

(2) different gold carpet materials and shapes (3) equip metal sluice cap and lock keep gold safe.

Gold Ore Milling Machine

Grinding liberates more gold from gold ore in quartz, gold ore in granite, gold stones, gold hard rocks, tailings and black sand. Insufficient grinding causes a loss in gold recovery. Over-grinding results in higher unit cost in energy, grinding media, and reagent consumption. Commonly used gold mills are ball mills and wet pan mills.

Ball Mill

- Ball milling methods include “dry” and “wet” grinding. Gold ore grinding plants often apply wet grinding.

- In most cases, the inner surface of the shell is coated with wear-resistant linings for longer service life.

- To improve the grinding efficiency, add a classifier to form a closed circuit, ration steel balls reasonably.

Gold Ore Rock Crusher

The primary purpose of the gold ore rock crusher is to crush hard quartz rocks containing gold into smaller pieces, with a particle size of less than one inch, in order to enhance grinding efficiency. Typically, a jaw crusher is selected as the main gold ore crusher, while a hammer crusher serves as the secondary rock crusher for gold.

Jaw Crusher

Jaw crushers are categorized into large (>600mm), medium (300-600mm), and small (<300mm) jaw crushers based on the width of the feeding port.

Jaw plates tend to wear out. Fote utilizes high manganese steel and other wear-resistant materials for jaw plates, extending their lifespan.

Replacing the jaw plates is a simple task. Just remove a few bolts and replace them.

Gold is a special currency for reserves and investment, and it is also an important material for jewelry, electronics, modern communications, aerospace and other sectors. The value of gold motivates people to prospect, mine and process more gold ore to extract more gold. That’s why you need gold mining equipment, more specifically mineral processing equipment.

GUOGAO company is committed to providing gold miners with efficient and robust gold mining equipment starting from crushing, grinding, gravity separation, flotation, helping them get a high gold recovery rate.

Whether you are extracting gold from alluvial gold, placer gold, gold ore in quartz, gold stones, or separating gold from lithium, silver, iron, copper, cobalt and lead, you need gold beneficiation equipment (often called gold recovery equipment). Commonly used are gravity gold recovery equipment, gold flotation equipment, and gold magnetic separator.

Hammer Crusher

There are different types of hammer crushers, with the most commonly used being single rotor and ring hammer crushers.

Various materials are used for the hammerhead depending on the hardness of the rocks. High manganese steel hammerheads are utilized to break hard quartz.

The grate of the small hammer crusher is made of alloy steel material that has high hardness and good wear resistance, which extends its service life.