Gold gravity separation is a highly effective extraction method that relies on the physical properties of gold, such as its density, specific gravity, size, and shape, to separate it from other minerals.

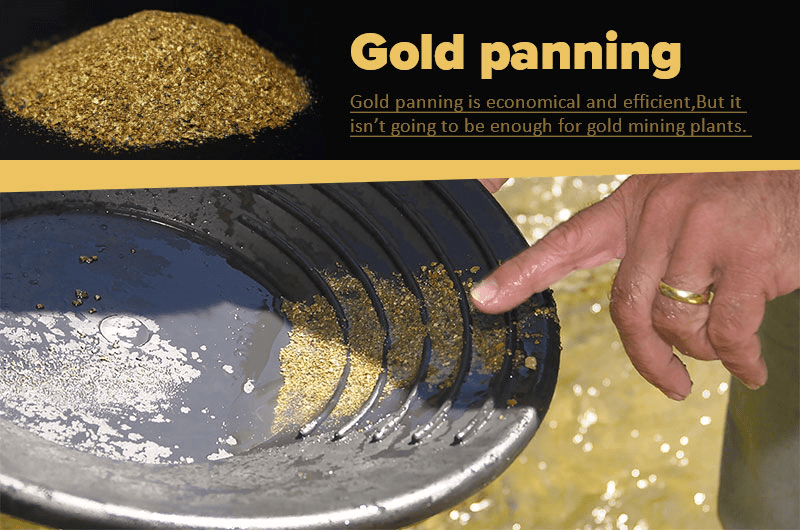

Panning for gold is a basic and straightforward gravity separation method used to extract gold from placer deposits. To do this, scoop placer gold ores into a pan and gently agitate them in water until the gold settles at the bottom of the pan.

Gold panning is cost-effective and efficient for amateur gold miners, but it falls short for larger-scale gold mining operations. Specialized equipment like shaking tables, spiral chutes, and jigs are commonly used to capture substantial quantities of both coarse and fine gold in a faster and more efficient manner.

Shaking table

A shaking table, also referred to as a gold shaker table, is a piece of gravity separation equipment. It utilizes the specific gravity difference between gold and waste minerals, along with the alternating movement of the bed surface and transverse oblique water flow through riffles or notches, in order to separate gold from waste minerals.

What are they good at:

Gold shaker tables excel in sorting fine-grained minerals. They come with varying effective recovery particle sizes to accommodate ores of different sizes. Shaker tables designed for coarse ores have a maximum feed particle size of 2mm, while those for fine ores have a limit of 0.5mm, and for slime, it is 0.15mm.

Gold shaker tables find frequent application in concentration processes.

What we love:

- It has high separation efficiency.

- The operation is simple, and it can be operated automatically after installation and debugging.

- It requires no reagents, making it environmentally friendly and cost-effective.

- It has multiple models available to process gold ore with different particle sizes.

We don’t like this as much:

- Compared to spiral chutes and jig machines, it has a smaller processing capacity and occupies more space.

- It requires high assembling accuracy.

- Since the shaker table is mostly fixed on the cement floor or steel channel, it is inconvenient to move.

Price:

For large and medium-sized gold processing plants, at least one large shaker table is needed to increase the gold recovery rate. The price of such a table starts at $1500.

For small gold processing plants, a mini shaker table can be used for as little as $400.

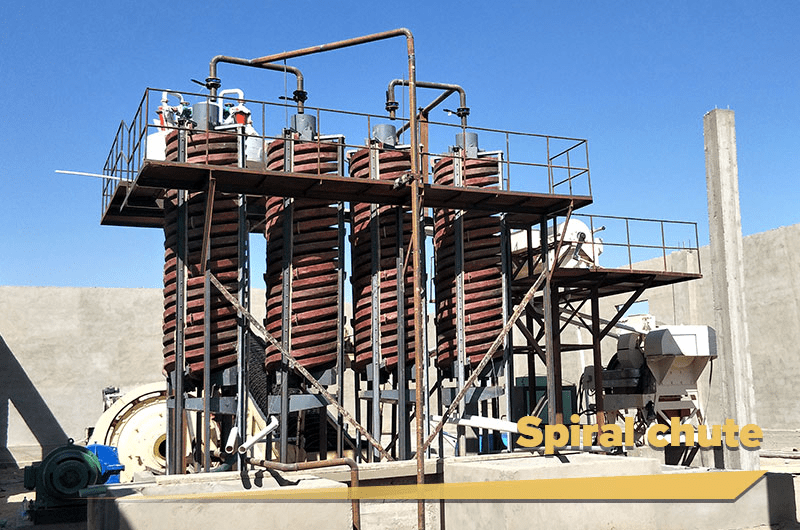

Spiral chute

A spiral chute, also known as a gold spiral separator or spiral concentrator, separates minerals with different specific gravity based on how they move in response to gravity, centrifugal force, and other forces in the fluid medium.

What is it good at:

The spiral separator is ideal for processing alluvial gold ore, particularly when the gold ore has a high degree of individual particle separation and a flat shape. Additionally, it excels in handling fine gold ore with particle sizes ranging from 0.003-0.6mm and low mud content.

Spiral chutes are commonly employed for preliminary concentration purposes.

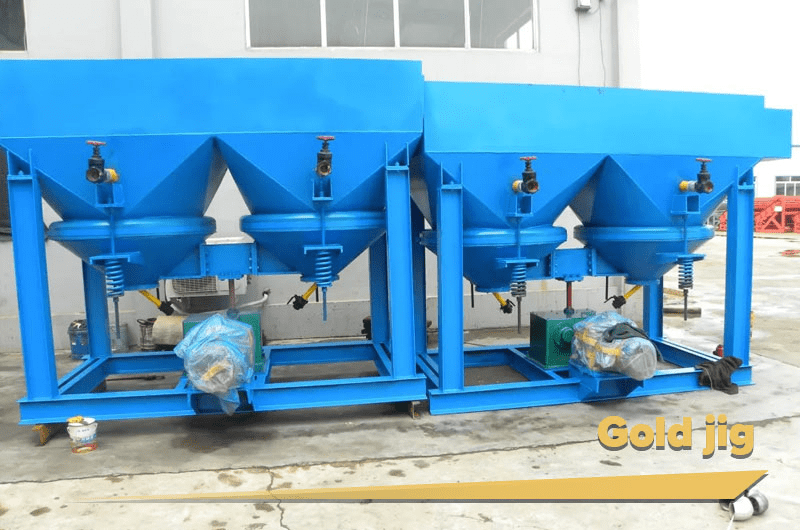

Gold jig

Jig Concentrator is an effective machine that uses gravity separation based on the density difference of ore materials. It is mainly used for processing placer gold, coltan, tungsten, tin, and other minerals. The higher the density difference, the better the jigging separation effect.

There are different types of jig concentrators available: eccentric jig concentrator (plunger jig and diaphragm jig), hydraulic jigger, movable sieve jig, air pulsating jig, and trapezoid jig. The diaphragm jig has high beneficiation efficiency and can process coarse particle ores such as tungsten and tin with a particle size ranging from 0.5 mm to 16 mm.

The trapezoidal jig has a large processing capacity and can handle particles ranging from 50 mm to 0.25 mm. It has been widely used in tungsten, tin, and iron ore dressing plants. Depending on the beneficiation medium used, mineral jigs are divided into hydraulic jigs and dry jigs; dry material feeding yields better results.

The GUOGAO sawtooth jig machine uses water as the medium for fine gold recovery with low water consumption and continuous operation.

Before using the sawtooth jig machine: feed by belt conveyor or slurry pump automatically based on height difference or gravity flow. After using the sawtooth gig machine: separate gold concentrate onto a gold shaker table while sending tailings to a sluice box.

GUOGAO is a manufacturer of various types of mineral processing equipment including fixed jigs and mobile jigs machines customized according to your requirements. JXSC has been focusing on gravity separation techniques in mineral processing for decades offering more gravity separator machines such as spiral chutes,jigger machines (mineraljig concentrators),shaker tables,and centrifugal concentrators.