Placer mining is commonly employed for precious metal deposits, especially gold, and gemstones. These valuable resources are frequently discovered in alluvial deposits, which consist of sand and gravel found in modern or ancient stream beds, or sometimes glacial deposits. Due to the heavier density of gems and heavy metals like gold compared to sand, they tend to gather at the bottom of placer deposits. It should be noted that these metal or gemstone concentrations make up only a small fraction of the overall deposit as they have been transported by stream flow from their original source such as a vein.

The word “placer” comes from the Spanish word “placer,” which means shoal or alluvial/sand deposit. It originates from “plassa” (place) in Medieval Latin, the root of the English words “place” and “plaza.” In Spanish, it directly refers to a sand or gravel deposit formed by alluvial or glacial processes.

An area well protected from water flow is an excellent location for finding gold. Gold, which is very dense, is often found in stream beds. Different types of gold deposits are handled differently. Prospectors are attracted to placer deposits because they have low costs. Gold can be found in various places, including residual, alluvial, and bench deposits.

Residual

Residual deposits are more common where rocks have undergone weathering without the presence of water. These deposits have not yet been washed away or moved. Residual deposits typically occur at the site of the lode and undergo rock weathering.

Alluvial

Alluvial or eluvial deposits are the most common type of placer gold and tend to be the richest. They consist of pieces of gold that have been carried away from the lode by water force and deposited in sediment near or within watercourses. As a result, they are mostly found in valleys or flood plains.

Bench

Bench deposits form when gold reaches a stream bed. High accumulations of gold in old stream beds are referred to as bench deposits. They can be found on higher slopes that drain into valleys and sometimes even on mountaintops far from other water sources. Many miners nowadays focus their activities on bench deposits.

Deep leads

Deep leads form when former stream beds become covered by later sediments or igneous rock resulting from volcanic eruptions. Examples exist in Australian goldfields such as Gulgong and Creswick.

Accessing the gravel containing gold requires shafts and drives similar to underground mining techniques but it is typically processed like alluvial gold.[6][7] In some cases, heat associated with igneous lava flows altered the gravel containing gold so that it needed to be crushed before extracting the precious metal; Forest Reefs in Australia provides an example of this kind deep lead.[8]

Methods

Various methods are used for mining placer gold and gems both for extracting the minerals from the ground and separating them from non-gold or non-gem materials.

Panning

Gold panning in Korea, c. 1900

Main article: Gold panning

The simplest technique for extracting gold from placer ore is panning. This technique dates back to at least the Roman Empire.[9] In panning, a portion of mined ore is placed in a large metal or plastic pan along with a generous amount of water. The mixture is then agitated so that the gold particles, being denser than other materials, settle to the bottom of the pan. The lighter gangue material such as sand, mud, and gravel are washed over the side of the pan, leaving behind the gold. Once a placer deposit is discovered through gold panning, miners usually switch to equipment that can process larger volumes of sand and gravel more efficiently. While gold panning was commonly used during the California gold rush,[10] it is now rarely employed for profit since even an experienced prospector can only process approximately one cubic yard of material every 10 hours of work.

Methods

Various methods are employed to extract placer gold and gems, both in terms of mineral extraction from the ground and separation from non-gold or non-gem materials.

Panning

Gold panning in Korea, c. 1900

Main article: Gold panning

The simplest technique for extracting gold from placer ore is panning. This method can be traced back to at least the Roman Empire.[9] In panning, a portion of mined ore is placed in a large metal or plastic pan along with a generous amount of water. The mixture is then agitated so that the denser gold particles settle to the bottom while lighter gangue materials like sand, mud, and gravel are washed over the side of the pan. This leaves behind the gold. Once a placer deposit is discovered through gold panning, miners typically switch to equipment that can process larger volumes of sand and gravel more efficiently. While gold panning was commonly used during the California gold rush,[10] it is now rarely employed for profit since even an experienced prospector can only process approximately one cubic yard of material every 10 hours of work.

Rocker

A rocker box, also known as a “cradle,” can process more material than a gold pan but is still limited compared to other placer mining methods. It can only handle about 3 or 4 yards of gravel per day.[11] Unlike a sluice box, it is portable and requires less infrastructure. The rocker box sits on rockers that separate the gold, earning it the nickname “rocking the golden baby.” A typical rocker box measures approximately 42 inches long, 16 inches wide, and 12 inches deep with a removable tray at the top for placing gold.[12] While popular during the early gold rush in North America, its usage declined as other methods capable of handling larger volumes became more common.[11]

Sluice Box

For information about sluices in general, see sluice. For Sluice Boxes State Park in Montana, see Sluice Box.

Gold specks (small) and pebbles (large) caught by riffles in a sluice box

A modern metal sluice box with riffles at its base to catch settling gold particles

The same principle can be applied on a larger scale by constructing a short sluice box with barriers called riffles along the bottom. These riffles trap heavier gold particles while water washes away other materials along the box. This method is better suited for using shovels or similar tools to feed ore into the device. Sluice boxes can range from just a few feet to over ten feet long (commonly referred to as a “Long Tom” if over six feet). Although they can handle larger volumes of material compared to simpler methods like rocker boxes or gold panning, their efficiency may suffer since conventional sluice boxes typically recover only around 40% of processed gold.[13]

Placer mines in Park County, Colorado during the 1870s featuring an extended sluice box.[14]

During the California gold rush, sluice boxes were extensively used for larger-scale operations. As streams became depleted, variations of the sluice box such as the grizzly and undercurrent were developed. The grizzly consists of parallel bars placed at a 45-degree angle over the main sluice box to filter out larger materials. The undercurrent variant includes additional auxiliary sluice boxes where initial material filtration occurs before traveling through a trough into the primary sluice box for further filtering. Both the grizzly and undercurrent designs aim to increase efficiency and are often used in combination.[11]

Dry Washing

For more information about drywashing, see Drywasher.

Sluicing is only effective in areas with sufficient water supply and impractical in arid regions. Alternative methods that utilize air blowing to separate gold from sand have been developed. One common method is Mexican dry washing, which involves placing gravel on a riffle board with a bellows underneath it. The bellows blows air through the board to remove lighter materials while retaining heavier gold.[15] Using this technique, approximately 1 1/2 to 4 cubic yards of gravel can be processed per day with a maximum efficiency of 80%.[16] Another form of dry washing is called “winnowing.” This method was commonly employed by Spanish miners in America and only requires a blanket and a screened box. Material passes through the box so that only finer particles remain on top of the blanket. The material on the blanket is then tossed into the air, allowing any breeze to blow away lighter materials while leaving behind gold particles. Although simple and requiring minimal equipment, this method is slow compared to other techniques.

Gold Panning

In gold panning, mined ore is placed in a large metal or plastic pan along with ample water and agitated so that denser gold particles settle at the bottom while lighter gangue materials like sand, mud, and gravel are washed over the pan’s edge. Once a placer deposit is discovered through gold panning, miners typically switch to equipment that can process larger volumes of sand and gravel more efficiently. While gold panning was commonly used during the California gold rush,[10] it is now rarely employed for profit since even experienced prospectors can only process approximately one cubic yard of material in 10 hours of work.

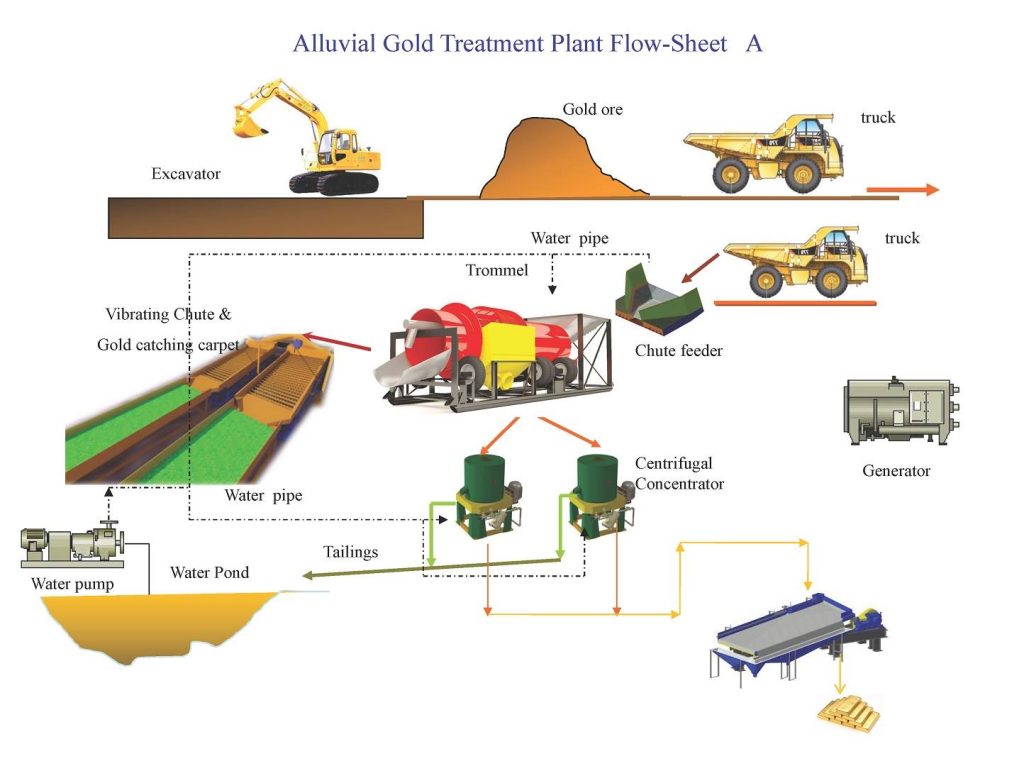

Trommel

A trommel is a rotating metal tube with a screen at one end. Inside the tube, there are lifter bars that help separate valuable minerals from the ore. The ore is fed into the elevated end of the trommel and water, often under pressure, is used to wash away the minerals. The screened ore can then be further concentrated using smaller devices like sluices and jigs. Any larger pieces of ore that don’t pass through the screen are carried away by a conveyor.

Gold dredge

Mechanical dredges are used for large-scale sifting of placer gold from alluvial deposits. These dredges were originally big boats capable of processing large amounts of material. However, as easily accessible gold has become depleted, smaller and more maneuverable dredges have become more common. These smaller dredges use pumps to suck up water and gravel through long hoses, allowing for separation of gold using traditional methods like sluice boxes.

Underground mining

In areas where the ground is permanently frozen, such as Siberia, Alaska, and Yukon, underground mining may be done on placer deposits. Since frozen ground cannot be mined by hand due to its hardness, historically fires were built to thaw it before digging began. Later methods involved blasting jets of steam into frozen deposits.

Deep leads in underground mining are accessed using techniques similar to conventional underground mining.

Environmental effects

While not mandatory, process water can be continuously recycled in modern placer mining operations and reclaimed after extraction of sought-after minerals (known as “tailings”). Although these recycling and reclamation processes are more common today, they’re still not universally practiced.

View of Las Médulas

In ancient times when process water wasn’t typically recycled and spent ore wasn’t reclaimed either; remains from Roman alluvial gold mines at Las Médulas justify their designation as UNESCO World Heritage sites due to their spectacular nature. Pliny the Elder described Roman miners’ methods in his work Naturalis Historia, published around 77 AD. He witnessed large-scale hydraulic mining of placer deposits and noted that the local lake Carucedo had been heavily silted by these mining techniques.

Environmental activists criticize hydraulic mining as environmentally destructive due to the significant amount of silt it adds to previously clear streams (also known as the “Dahlonega Method”). Most placer mines today use settling ponds to ensure sufficient water for their sluicing operations.

In California, from 1853 to 1884, “hydraulicking” removed a massive amount of material from gold fields. This material was carried downstream and raised the level of certain areas in Central Valley by about seven feet. It also settled in long bars up to 20 feet thick in parts of San Francisco Bay. The opposition group called themselves the “Anti-Debris Association.” In January 1884, the North Bloomfield Mining and Gravel Company case banned flushing debris into streams, effectively ending hydraulic mining mania in California’s gold country.