Promising Outlook for Gold

Currently, countries worldwide are gradually recovering from the impact of Covid-19. As the economy enters a phase of recovery, there will be an increase in gold consumption driven by economic prosperity. The recognition of gold as a defensive asset further contributes to a positive outlook for the gold spot market in the future.

Positive Prospects for Gold

According to Markets Insider, international gold prices have experienced a significant upward trend over the past five years. In 2021, gold was reported to be valued at over $1,700 per ounce.

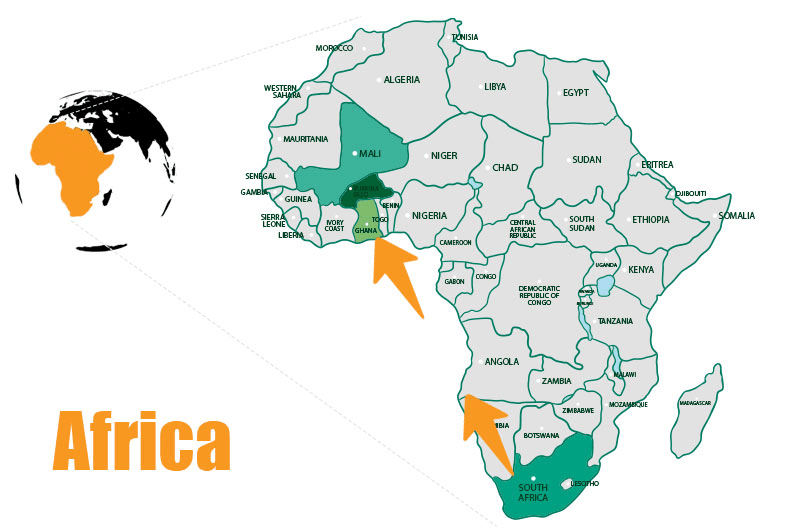

Africa Ranks Third as Largest Gold Producer

With increasing demand for gold, bankers, mining companies, and individuals alike have shown great enthusiasm in seeking this precious metal. Traditionally dominated by South Africa, African gold mining has now shifted its focus to countries such as Ghana, Mali, and Burkina Faso.

Currently, Ghana is a top global gold producer and the largest in Africa, producing approximately 150 metric tons of gold in 2020.

South Africa contributes 4.2% to the world’s precious metal production through its gold mines. South Deep holds the title for being the largest gold mine globally, while Mponeng Mine boasts as the deepest. TauTona Mine also hosts one of the world’s deepest mining operations, competing only with Mponeng Mine.

Gold processing plants in Africa

Do you know which types of gold ore are most popular among Africans? Alluvial gold, placer mine, rock gold, gold sulfide ore, and oxidized gold ore can be processed into valuable items such as gold bars and jewelry.

So, how can we obtain the maximum amount of gold at a lower cost?

- Nigeria 80 TPH alluvial gold & placer mine processing plant

The Nigeria gold processing plant processes mud-containing alluvial and placer gold ores, primarily in particle form. It has a production capacity of 80 t/h. The feed size ranges from 0 to 200 mm, while the size of the placer gold is between 0 and 3 mm.

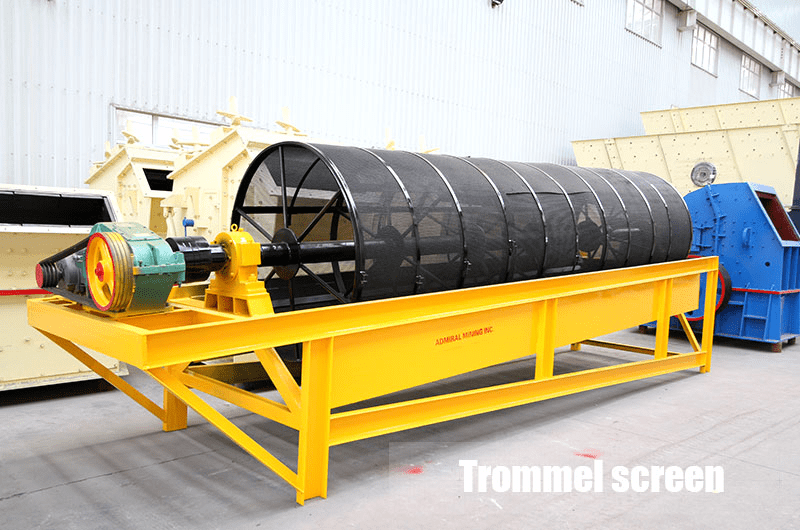

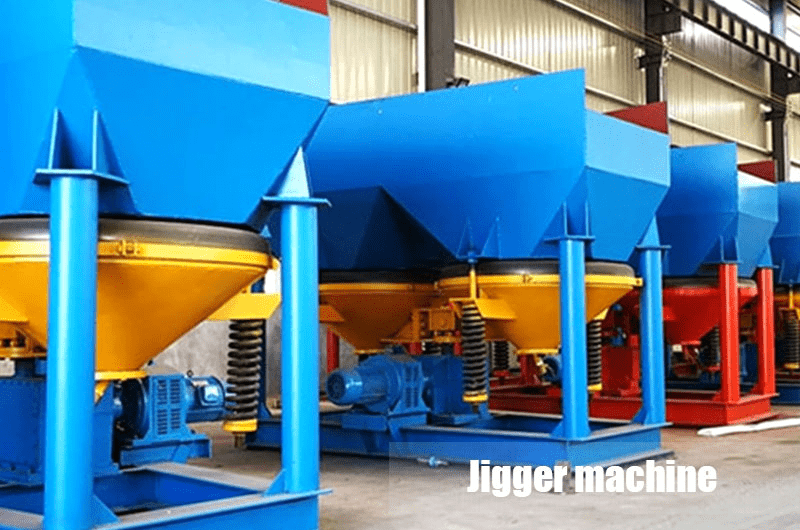

The gold processing plant utilizes the gravity separation method, with equipment consisting of a trommel screen, jigger, and shaking table.

Steps for gold processing:

- Wet crushing and washing

A vibrating feeder feeds large raw gold ore into a trommel screen. The high-pressure water in the drum crushes and washes the ore that contains clay and silt. Coarse ore is discharged from the tail of the screen, while fine ore enters a jigger.

- Beneficiation

The coarse-grained material without gold and the fine-grained material with higher gold content are sent to a jigger for initial sorting and efficient concentration. The valuable concentrate is obtained from the jigger’s tailings.

- Gold Extraction

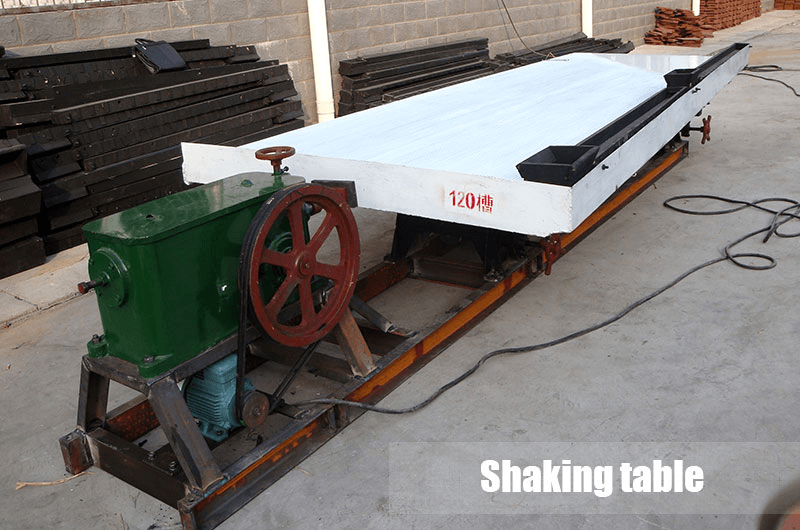

Next, the gold is concentrated using a shaking table to obtain a high-grade gold concentrate.

Fote reviews:

The trommel screen can process soil containing alluvial gold, placer gold, and river mud gold. It is an economical, simple, and efficient method for rapid and large-volume processing.

The jigger is a gravity beneficiation equipment used to recover most useful minerals due to the relatively high density of gold (19.3 grams per cubic centimeter) and the significant density difference between gold and gangue.

The shaking table is highly effective in separating different particle sizes: coarse sand (2-0.5mm), fine sand (0.5-0.074mm), and slime (-0.074mm). Its separation efficiency surpasses that of other fine-grain gravity separation equipment. The shaking table concentrates a substantial amount of gold ore at once, resulting in highly enriched gold concentrate.

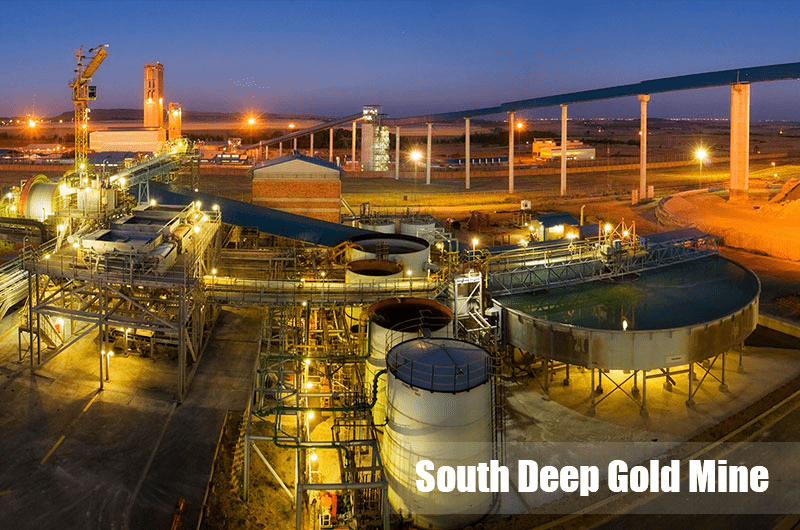

- South Africa 600 TPD low-grade rock gold processing plant

A sulfide gold mine with complex composition undergoes rock-gold processing at a plant in South Africa with a production capacity of 6000 tons/day. The feed size is 100 mm.

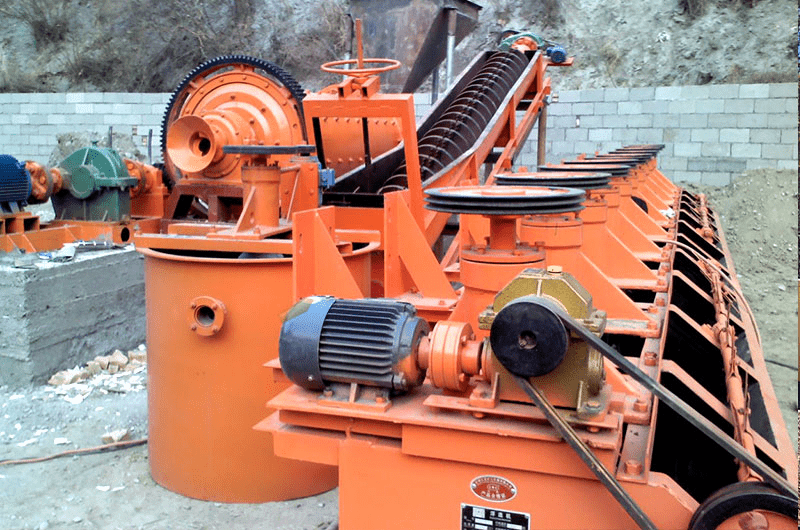

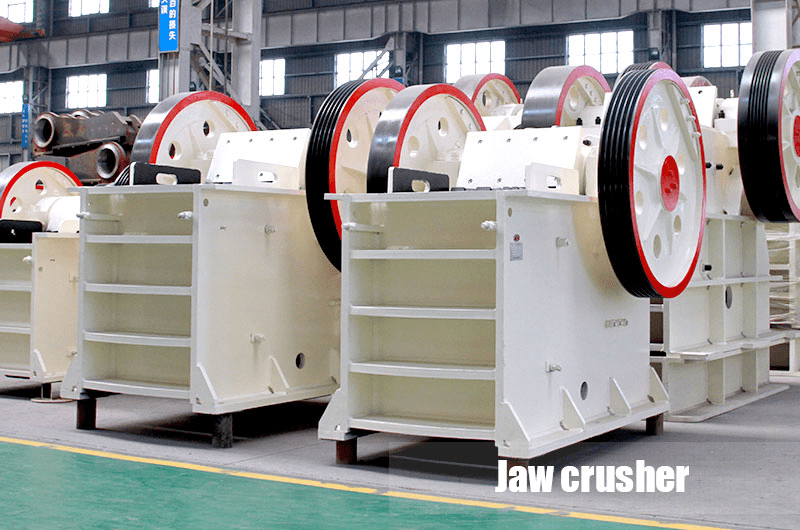

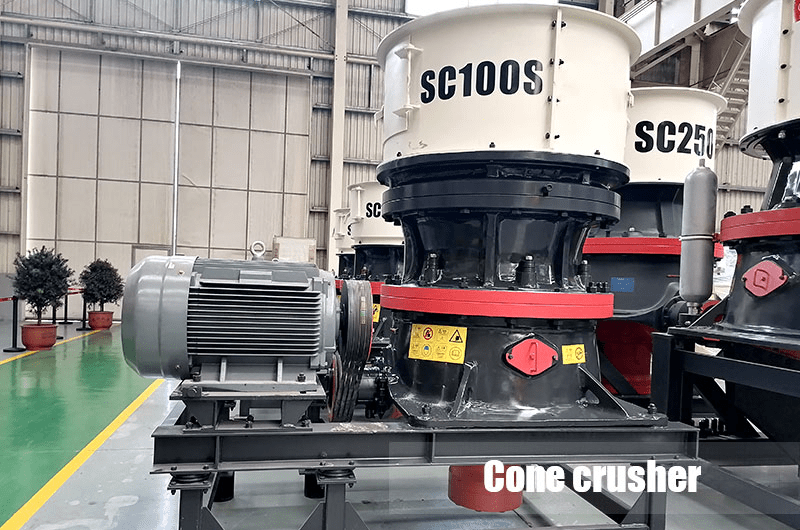

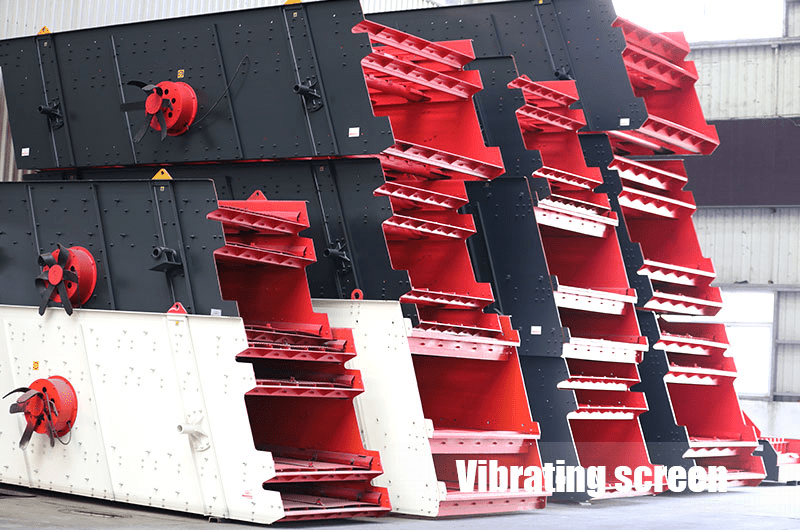

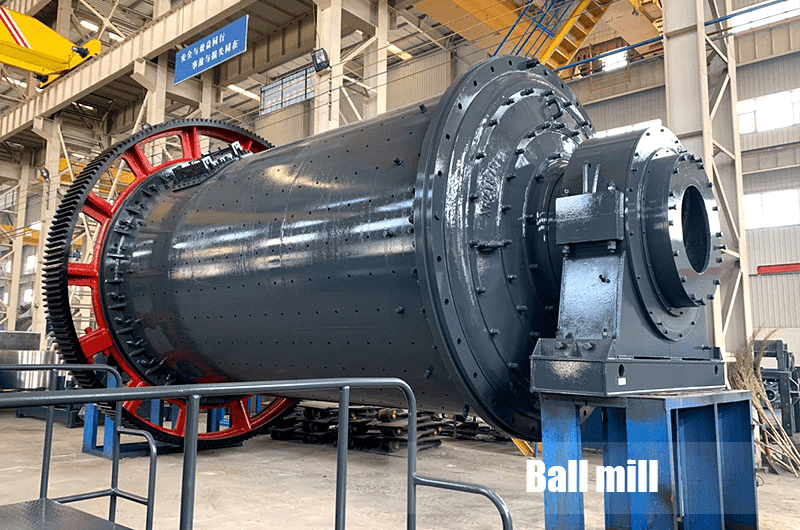

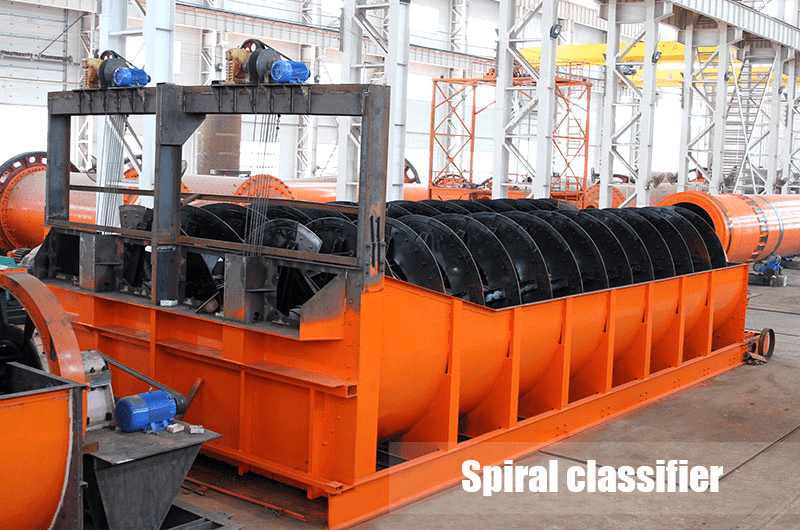

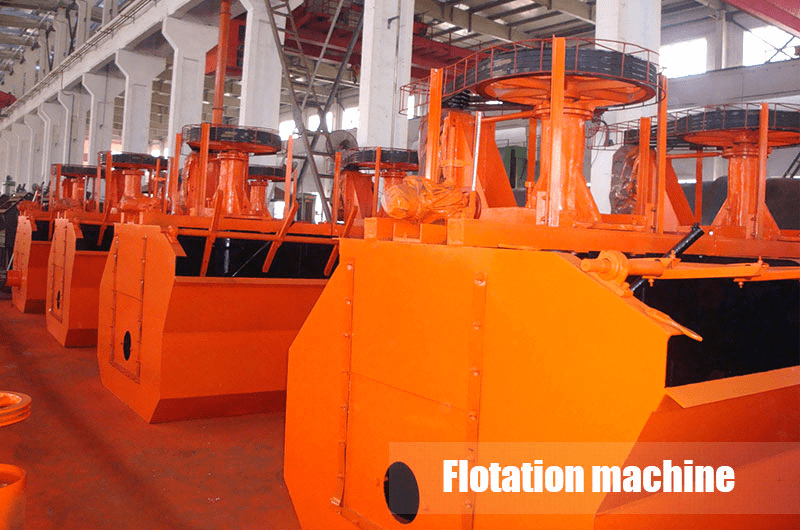

The plant utilizes the flotation method. The equipment setup includes a jaw crusher, cone crusher, vibrating screen, ball mill, spiral classifier, and flotation machine. The ultimate gold recovery rate is approximately 70%.

Steps for gold processing:

- Crushing in two stages

Large gold ore is fed into a jaw crusher for coarse crushing and then enters a cone crusher for fine crushing to eliminate gangue minerals.

- Screening

The crushed gold ore is screened by a vibrating screen

- Grinding

Once screened, the gold ore is fed into a ball mill for grinding, with a required fineness of above 180 mesh.

- Classification

The crushed gold ore is fed into a classifier. The refined gold ore is then directed to the flotation machine, while the remaining unrefined ore undergoes further grinding.

Flotation:

Add reagents to the flotation machine and mix them to obtain a high-grade gold concentrate.

GUOGA reviews:

When the composition of gold ore is complex and gravity separation becomes difficult, flotation is the best option. However, a large amount of capital is required.

During flotation, valuable minerals accumulate as foam on top of the flotation machine. By scraping off these foams, we obtain gold concentrate, while useless minerals sink to the bottom of the tank and are discarded as tailings.

- Tanzania 10 TPH rock gold processing plant

The Tanzanian gold processing plant processes rock gold, which is oxidized ore with very fine particle size. The production capacity is 10 tons per hour and the feed size ranges from 0-125 mm.

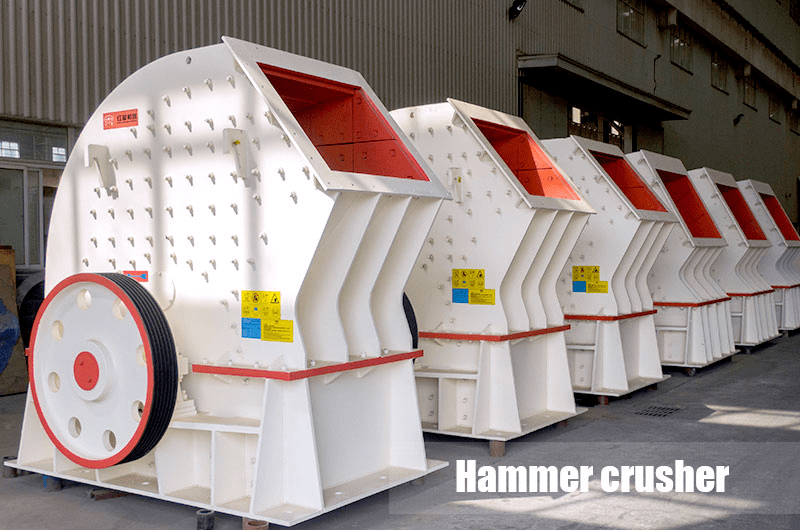

The plant utilizes the gravity method and is equipped with a jaw crusher, hammer crusher, ball mill, and shaking table. As a result, the free gold recovery rate reaches 97%. This plant is highly favored by African gold miners due to its low cost and quick return compared to flotation plants.

Steps for gold processing:

- Crushing in two stages

Firstly, large gold ore is crushed by a jaw crusher and then further crushed by a hammer crusher.

- Grinding

Afterwards, the gold ore is fed into a ball mill to be ground into gold powder, ensuring complete liberation of free gold.

- Gold extraction

Finally, the gold ore is sent to a shaking table where it is recovered and enriched, resulting in the production of gold concentrate.

Additionally, popular methods for extracting gold include the Gold Cyanide Process, Carbon Pulp Gold Extraction Process, and Resin Pulp Gold Extraction Process. These methods are all based on processing ground gold ore.

Gold Cyanide Process: Ground gold mines are treated with a cyanide-containing solution to separate solids from clear solution; precipitation method is used to recover gold from zinc powder solution. Metso offers a leading process for gold cyanidation.

Carbon Pulp Gold Extraction Process (CIP/CIL): This process utilizes activated carbon for recovering gold. Activated coconut carbon is added to the cyanide ore slurry to adsorb dissolved gold which can then be extracted. Mesto also possesses mature CIP/CIL technology.

Resin Pulp Gold Extraction Process: Ion exchange resin can extract gold from pulp as well. This process involves adsorption of solid spherical polystyrene resin beads onto which the gold adheres. SGS is a renowned manufacturer of Resin Pulp Gold Extraction equipment and was recognized as one of Forbes’ best multinational companies in 2017.

Conclusion

Africa boasts abundant reserves of valuable golden resources. To maximize output while minimizing costs, establishing an efficient and effectivegold processing plant becomes crucial.

GUOGAO With over 40 years of experience in manufacturinggold processing equipment,GUOGAO Machinery has successfully assisted African countries such as South Africa,Nigeria,Zambia,Sudan,Ghana,Kenya,and others in setting up large-scale or small-scalegold processing plants.All machines can be tailored according toyour specific requirements